Charging an inverter charger from another inverter

Oct 24, 2020 · Well I run 2 systems : one, 12v with 2 225ah 6v lead acid batteries with a 2500 watts inverter; the other, 24v with 4 225ah 6v lead acid batteries with a 3000 watts inverter

Get Started

12V To 120V Converter Guide & Types | What You Need To

Jan 11, 2025 · Discover everything you need to know about 12V to 120V converters. From types and functions to installation tips and troubleshooting common issues, this guide will help you

Get Started

12V vs 24V inverter

Oct 22, 2023 · This article introduces how inverter works and compares 12V vs 24V inverter, including the applications, costs, and other differences, also

Get Started

Understanding the Compatibility of 12V Solar Panels with 24V

Apr 7, 2025 · The rise of renewable energy sources has sparked a significant interest in solar power, with many people seeking to harness the sun''s energy for personal and commercial

Get Started

What''s a better plan, 24v direct or 24v inverted to 110v?

Jun 20, 2022 · You could get 10%-20% more use out of your batteries for the DC-only loads versus running those same loads through the inverter. But the gains may be lowered slightly if

Get Started

Can I Run a 12V Inverter on a 24V Battery?

Apr 10, 2025 · It is not feasible to connect a 12V inverter directly to a 24V battery. 12V inverters are designed to accept an input voltage of 12V, while 24V is clearly beyond their operating

Get Started

12V Inverter vs 24V Inverter — What Is The

Dec 11, 2024 · This article will explore the differences between 12v inverter vs 24v inverter, considering factors such as energy loss, battery requirements, and

Get Started

I am ready to convert! From 12 volts to 24

Nov 4, 2023 · If I''m grokking correctly, you''re after the Growatt 3kw 24v AIO, set to SBU and configured to start AC charging at 12.9v. There are 2 screws in the front cover (they''re marked

Get Started

What Is a 12V to 24V Converter?

Nov 8, 2021 · Can You Convert 12V to 24V? Yes! you can step voltage up or down for various uses. It''s possible, using your normal 12V batteries or a

Get Started

24V to 240V Power Inverters | Convert DC to AC

Browse our selection of 24V inverters and inverter/chargers, perfect for converting DC power to 240V/230V AC power. Ideal for trucks, buses and boats.

Get Started

12V VS 24V Inverter: What are the Differences

When it comes to choosing the right inverter for your power needs, understanding the difference between 12V and 24V systems is crucial. Both options have

Get Started

12V vs 24V Inverter: What''s the difference

What''s the Difference Between a 12 and 24 Volt Inverter? The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the

Get Started

How to Charge a 24v System With a 12v Charger

May 31, 2023 · RV, EV, boats or UPS systems use a 24v battery system that is robust to power even industrial tools. Learn how to charge a 24v system.

Get Started

Building or buying a 12V DC to 24V AC inverter

Mar 13, 2025 · Has anyone come across a small 24V inverter device, or can help with a circuit to produce enough 24V AC current from 12V DC to drive up to 8

Get Started

12V vs 24V Inverter:Which is Better for My

Nov 5, 2024 · Q: Can a 24V inverter be connected to a 12V battery? A: A 24V inverter should be connected to a battery system with a 24V output voltage to

Get Started

DC 12V to AC inverter: can make a product to

Jan 26, 2020 · For example, this product https://amzn.to/2RSJmmN can convert DC 12V to AC 110V, or DC 24V to AC 220V; can I have 2 set of 12V batteries in series to get DC 24V, then

Get Started

24v system: series vs. parallel battery options

Jul 13, 2022 · With two 12V batteries, you can disconnect them from each other before moving them. Not so with a pre-assembled 24V battery. To expand the 24V battery, you would add

Get Started

How Do Inverters Work? – JMBatteries

Jul 15, 2025 · Step 3: Voltage Adjustment The raw DC voltage (e.g., 12V, 24V, or 48V from a lithium battery) is stepped up to 120V/240V AC (standard household voltage). Step 4: Power

Get Started

24V solar system

Jun 6, 2022 · With the system you''ve designed, with batteries, solar charging, and inverter/charger at 24V, and using a 24V-12V DC to DC converter at 90+% efficiency to run

Get Started

Can I Connect a 12V Inverter to a 24V Battery Bank

Jun 3, 2025 · Some inverters have built-in protections that might shut them off immediately, but if not, components could burn out, making the inverter unusable. Is a DC-DC converter the best

Get Started

12V vs 24V: What''s the Difference in Battery

Apr 23, 2025 · 2. Common Questions About 12V and 24V Battery Systems Can a 12V Battery System Be Converted to 24V? While two 12V batteries can be

Get Started

Can you run 12V system from 24V battery pack

Feb 4, 2023 · If I run two 12V batteries in series to supply 24V to a 24V inverter, can I run a small 12V rv system (mostly LED lights) tapped off one of the two batteries that is wired in series to

Get Started

24V to 12V DC Converter Circuit [using

Jan 19, 2025 · The DC to DC converter circuit described below can be used to convert a 24 V DC source into a 12 V DC output with high efficiency. Meaning,

Get Started

How To Convert 12V To 24V For Better Efficiency

Apr 13, 2020 · The only way to do what you are suggesting would be to still have a 12v battery/bank attached to the inverter, and use a smaller step down converter simply to charge

Get Started

Can I Run A 12V Inverter On A 24V Battery? Solutions And

Feb 6, 2025 · To use a 12V inverter with a 24V battery, you would need a voltage converter or a different inverter designed for 24V systems. These solutions can help convert the excess

Get Started

12V to 120V Inverter: How It Works & What You

Feb 17, 2025 · A 12V to 120V inverter can convert DC power (12V) into AC power (120V), making it compatible with household appliances. These inverters are

Get Started

12V vs 24V Inverter: What''s the difference

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the

Get Started

Thoughts on using a 24 volt to 12 volt step

Dec 23, 2021 · We recently got our $500 fixer upper pop up camper and our two Enjoybot 100ah 12v batteries. The camper does have a blown power

Get Started

Working Principle of Pure Sine Wave Inverter

Jun 6, 2022 · By varying the width of these pulses, the controller creates a series of pulses that approximate the desired sine wave shape. H-bridge inverter:

Get Started

6 FAQs about [Can the inverter 12v be converted to 24v ]

What is the difference between a 12V and 24V inverter?

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the electricity is converted from DC to AC. So a 12V inverter is designed for 12 volts input from the battery. And a 24V inverter is designed for 24 volts input from the battery.

Can a 12V inverter run on a 24v battery?

If you try to use a 12V inverter on a 24V battery it will be overloaded. Contrastingly, using a 24V inverter with a 12V battery will lead to a lack of electrical force. Knowing your inverter's voltage and what that means is critical in order for everything to run correctly.

What is the difference between 12V and 24v battery systems?

It depends on your system’s size, the quality of the inverter, and your power needs. In general, 24V inverters are better for larger systems, while 12V inverters work well for smaller setups. When choosing between 12V and 24V battery systems, it’s important to understand their differences. Let’s take a look the table below:

Should I convert 12V to 24V?

For example, If you have a 12V, 1200W battery, your rated current is 100A This requires thicker, more expensive wires than a 24V, 1200W counterpart. Therefore, the main advantage of converting 12V to 24V is less current. In effect, a lower current allows the use of thinner wires and leads to more minor system voltage drop.

Should I buy a 24V inverter?

24V Inverters: More efficient in larger systems since they require lower current, reducing energy loss and wire size. This can save energy, extend battery life, and use smaller components. However, the choice isn’t always simple. It depends on your system’s size, the quality of the inverter, and your power needs.

Why is a 24V inverter better than a battery?

This is because 24V inverters are more efficient, which means they lose less energy and cost less to run over time. Additionally, 24V systems need thinner and cheaper wiring because they use less current. However, 24V batteries and some components can be more expensive at the start.

Related Articles

-

Home 12V 24V Inverter

Home 12V 24V Inverter

-

The difference between 12v inverter and 24v

The difference between 12v inverter and 24v

-

Inverter 12v switch 24v price

Inverter 12v switch 24v price

-

62v inverter converted to 12v

62v inverter converted to 12v

-

Does the home inverter have 12v or 24v

Does the home inverter have 12v or 24v

-

Can UPS power supply be converted into 12V inverter

Can UPS power supply be converted into 12V inverter

-

What brand is good for 12v inverter 200v

What brand is good for 12v inverter 200v

-

How much does a 12v to 2400w inverter cost

How much does a 12v to 2400w inverter cost

-

How many watts does a 12v inverter have

How many watts does a 12v inverter have

-

12v battery inverter only

12v battery inverter only

Commercial & Industrial Solar Storage Market Growth

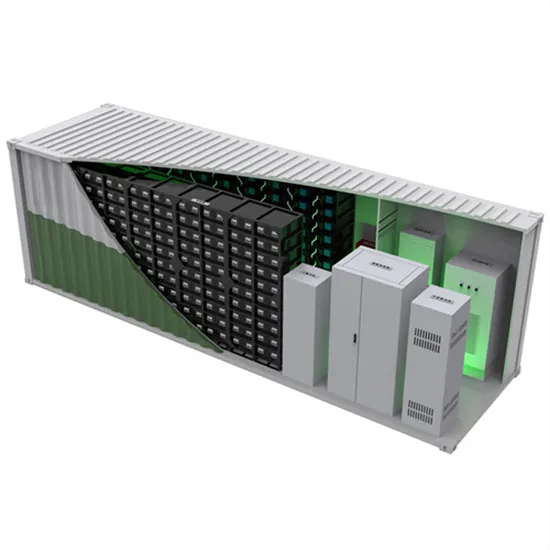

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.