Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Get Started

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

Get Started

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Get Started

Crystalline Silicon Terrestrial Photovoltaic Cells

4 days ago · Executive Summary and standard that applies to photovoltaic (PV) cells. Many PV module manufacturers depend on third party solar cell manufacturers for their supply of silicon

Get Started

Unraveling the pyrolysis behavior and co-pyrolysis

Jan 15, 2025 · The recycling of end-of-life crystalline silicon photovoltaic (PV) modules is essential for sustainable solar energy systems. This study investigates the pyrolysis behavior of

Get Started

Crystalline Silicon Photovoltaics

Mono-crystalline silicon solar cells have higher efficiencies than multi-crystalline silicon solar cells. In crystalline silicon photovoltaics, solar cells are generally connected together and then

Get Started

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The silicon energy bandgap determines the ultimate efficiency of PV cells made from c-Si; this value is 29.4%. As already explained in Section 8.4.2, c-Si solar cells have to be

Get Started

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Thin Film vs. Crystalline Silicon PV Modules The cost per watt of thin-film PV modules is lower than that of crystalline silicon modules. Though

Get Started

Short process recovery of silver and purification mechanism

Apr 15, 2025 · Abstract Photovoltaic (PV) devices, which are representative tools for generating renewable energy, have experienced record growth in terms of installed capacity, with

Get Started

Development of lightweight and flexible crystalline silicon

Oct 15, 2023 · Abstract Lightweight and flexible solar cell modules have great potential to be installed in locations with loading limitations and to expand the photovoltaics market. We used

Get Started

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Technologies based on crystalline silicon (c-Si) dominate the current PV market, and their MSPs are the lowest; the figure only shows the MSP for monocrystalline monofacial

Get Started

Characteristics of Crystalline Silicon PV Modules

Jan 21, 2022 · Monocrystalline silicon solar cells are more efficient than polycrystalline silicon solar cells in terms of power output. In order to increase

Get Started

Onyx Solar, Building Integrated Photovoltaics Solutions

2 days ago · To meet specific requirements, we offer two advanced photovoltaic (PV) glass technologies: amorphous silicon and crystalline silicon, both fully customizable. Our glass can

Get Started

Europe Crystalline Silicon Photovoltaic Glass Market: Market

Jul 8, 2025 · Europe''s focus on innovation drives the adoption of bifacial and anti-reflective coated crystalline silicon photovoltaic glass, optimizing performance in low-light climates and

Get Started

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Get Started

Green solvent hydrothermal recycling of end-of-life crystalline silicon

Jul 1, 2025 · Crystalline silicon PV modules (c-Si PV) typically exhibit service lifetimes of 25 years, with a substantial proportion reaching end-of-life prematurely due to performance degradation

Get Started

Crystalline Silicon Photovoltaics

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable,

Get Started

Delamination of components for recovery of waste crystalline

Jan 15, 2025 · Generally, crystalline silicon PV panels are composed of PV modules and metallic frames. PV modules are formed by lamination of tempered glass, solar cells, ethylene–vinyl

Get Started

Crystalline silicon solar panels photovoltaic

The International Technology Roadmap for Photovoltaic (ITRPV) predicts an upward trend for the shares of crystalline silicon (c-Si) bifacial PV cells and modules in the global PV market in the

Get Started

Crystalline silicon solar cell with an efficiency of 20.05 %

Oct 15, 2024 · A typical c-Si PV module, excluding the aluminum frame and junction box, comprises a laminated structure composed of glass, a crystalline Si solar cell, a Cu ribbon,

Get Started

The research progress on recycling and resource utilization

Jun 15, 2024 · Proposes PV subsidy policies and dynamic standard adjustments. The exponential growth in global photovoltaic installations has led to a continuous increase in photovoltaic (PV)

Get Started

CRYSTALLINE SILICON PHOTOVOLTAIC GLASS

2 days ago · Crystalline silicon photovoltaic glass is recognized for its superior energy output, yielding more energy than amorphous silicon glass under direct

Get Started

Lamination process and encapsulation materials for

May 21, 2024 · Introduction The majority of today''s crystalline silicon (c-Si) PV modules are manufactured in accordance with a glass-backsheet (GBS) module lay-up: 3.2–4mm glass at

Get Started

Crystalline Silicon PV Module Technology

Jan 1, 2013 · Wafer-based crystalline silicon (c-Si) solar cells require serial interconnection and packaging to render a product with reasonable voltage for outdoor use. This task is

Get Started

Effectively and completely separating the waste crystalline silicon

Jun 22, 2025 · Among various PV modules, crystalline silicon occupies more than 90 % of the market share due to its high power conversion efficiency, good environmental stability, and

Get Started

European Glass-Glass Photovoltaic Modules Are

Sep 23, 2021 · In a new study, researchers at the Fraunhofer Institute for Solar Energy Systems ISE have calculated that silicon photovoltaic modules

Get Started

Sustainable Strategies for Crystalline Solar Cell

Jul 7, 2024 · Solar PV is gaining increasing importance in the worldwide energy industry. Consequently, the global expansion of crystalline photovoltaic power

Get Started

Crystalline Silicon PV Module Field Failures

Jan 1, 2019 · Typical crystalline PV modules are composed of front glass (sometimes transparent fluoropolymers), encapsulant (majority is EVA, other less popular encapsulants include PVB,

Get Started

Slovakia Solar Photovoltaic Glass Market (2024-2030)

Market Forecast By Application (Residential, Non-Residential, Utility), By Type (AR Coated Solar PV Glass, Tempered Solar PV Glass, TCO Coated Solar PV Glass, Others), By End-User

Get Started

Effectively and completely separating the waste crystalline silicon

Jun 22, 2025 · In the industrial processing of silicon-based PV modules, PV glass and fluorinated backsheet are typically removed first using mechanical methods. The remaining module

Get Started

Glass Application in Solar Energy Technology

Apr 28, 2025 · Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass

Get Started

6 FAQs about [Slovakia crystalline silicon photovoltaic module glass]

What is crystalline silicon photovoltaics?

Crystalline silicon photovoltaics is the most widely used photovoltaic technology. Crystalline silicon photovoltaics are modules built using crystalline silicon solar cells (c-Si). These have high efficiency, making crystalline silicon photovoltaics an interesting technology where space is at a premium.

What are the different types of Photovoltaic Glass Technologies?

To meet specific requirements, we offer two advanced photovoltaic (PV) glass technologies: amorphous silicon and crystalline silicon, both fully customizable. Our glass can be customized to block the heat that enters the building and to provide the best insulation, thus avoiding the use of air conditioning and heating.

Is there a new LCI for crystalline silicon PV systems?

In late 2020, IEA PVPS released an updated LCI for PV systems that contains updates for crystalline silicon PV technology reflecting the year 2018, while some information, such as the amounts of auxiliary materials, are still based on 2011 .

What type of glass is used for solar panels?

Crystalline silicon solar cells are connected together and then laminated under toughened or heat strengthened, high transmittance glass to produce reliable, weather resistant photovoltaic modules. The glass type that can be used for this technology is a low iron float glass such as Pilkington Optiwhite™.

Are glass-glass PV modules a good choice?

Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet (a). Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life.

Can a photovoltaic system be installed in a European location?

"If I want to install a photovoltaic system in a European location with average irradiation values, I have a great influence on its climate friendliness with the choice of my PV modules," explains Dr. Holger Neuhaus, Head of Department for Module Technology at Fraunhofer ISE.

Related Articles

-

Crystalline silicon double glass transparent photovoltaic module

Crystalline silicon double glass transparent photovoltaic module

-

Myanmar crystalline silicon photovoltaic glass

Myanmar crystalline silicon photovoltaic glass

-

Solar photovoltaic module crystalline silicon

Solar photovoltaic module crystalline silicon

-

Crystalline silicon and thin-film architectural photovoltaic glass

Crystalline silicon and thin-film architectural photovoltaic glass

-

Photovoltaic module factory glass

Photovoltaic module factory glass

-

Photovoltaic module glass reflection

Photovoltaic module glass reflection

-

Price of crystalline silicon photovoltaic modules in Mumbai India

Price of crystalline silicon photovoltaic modules in Mumbai India

-

Silicon used in photovoltaic glass

Silicon used in photovoltaic glass

-

Glass and silicon wafers in the photovoltaic industry

Glass and silicon wafers in the photovoltaic industry

-

Mongolia photovoltaic module glass

Mongolia photovoltaic module glass

Commercial & Industrial Solar Storage Market Growth

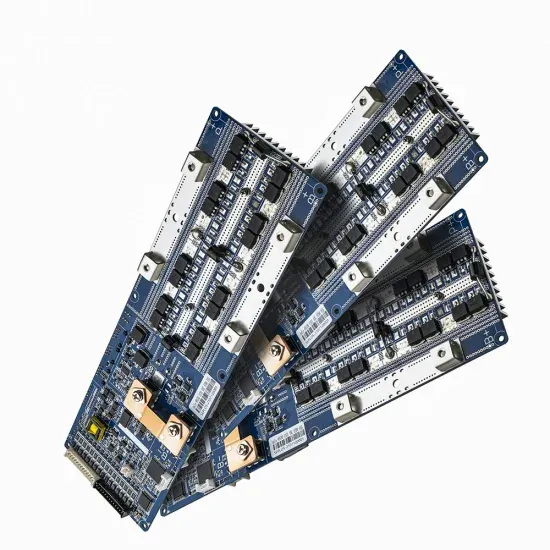

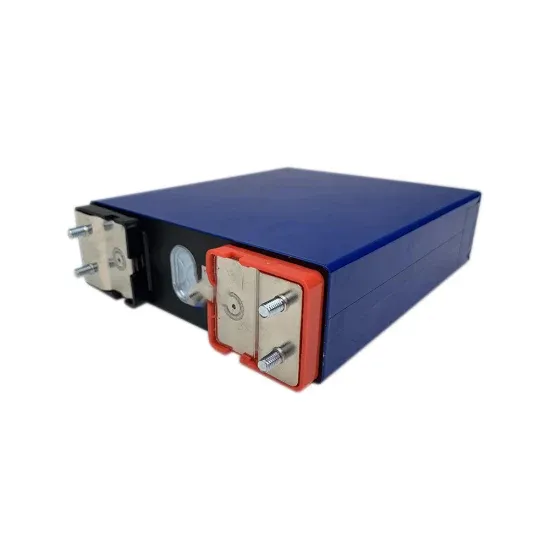

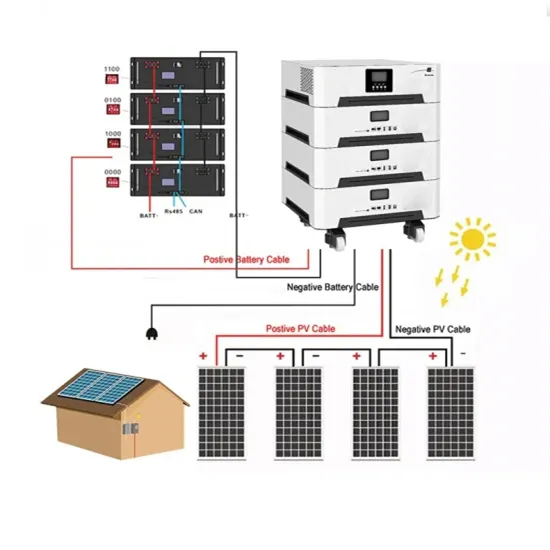

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.