Hithium plans 10GWh BESS assembly facility in

Jul 17, 2024 · Hithium has become the latest overseas player to seek to onshore production of battery energy storage system (BESS) equipment and

Get Started

Energy Storage & Conversion Manufacturing

Aug 31, 2023 · Accelerate innovation to manufacture novel energy storage technologies in support of economy-wide decarbonization. Who benefits from the manufacturing innovation?

Get Started

From Raw Materials to Reliable Power: Inside the Energy Storage

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get Started

A Collaborative Design and Modularized

Apr 4, 2022 · With the core objective of improving the long-term performance of cabin-type energy storages, this paper proposes a collaborative design and

Get Started

Prismatic Cell Assembly: The Powerhouse of

Feb 24, 2025 · Prismatic cell assembly is at the forefront of modern energy storage technology, revolutionizing industries with its compact design and high

Get Started

Energy Equipment and Systems

Energyequipsys highlights major theoretical achievements, numerical/computational simulations as well as experimental investigations of the energy production, conversion, and storage

Get Started

Inside the World of Battery Cell Manufacturing

Jun 24, 2024 · This guide to battery cell manufacturing explores the process from procurement to final assembly. We also shed light on the trends shaping the

Get Started

Leading Energy Storage Equipment

Are you looking for reliable and efficient energy storage solutions? Look no further than our high-tech enterprise, a leading innovator in the field of energy storage

Get Started

Cygni Energy opens 4.8GWh BESS assembly plant in

May 1, 2025 · Cygni Energy CEO and founder Venkat Rajaraman (centre) at the new factory. Image: Cygni Energy via X Cygni Energy, a manufacturer of electric vehicle battery packs and

Get Started

Battery energy storage systems | BESS

3 days ago · Battery energy storage (BESS) offer highly efficient and cost-effective energy storage solutions. BESS can be used to balance the electric

Get Started

Module and PACK Line (Energy Storage

The equipment has the advantages of automatic intelligent assembly and production from prismatic aluminum shell cell to module and then to PACK

Get Started

Energy Storage Cabinet Production Line

Aug 18, 2025 · This production line is used for automatic assembly of energy storage cabinets. All single machine equipment and distributed systems

Get Started

Battery gigafactory serving EV and BESS sectors

Aug 23, 2022 · Lithium-ion battery factory serving EV and ESS sectors has opened in New York State which could ramp-up to 38GWh annual production

Get Started

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · Production Line Overview Chisage ESS has been in the field of solar battery for many years and is committed to producing high-quality energy

Get Started

Battery production equipment and services

Jun 14, 2024 · Battery excellence for all manufacturing processes The increasing demand for clean energy is driving substantial growth in the battery industry. The advanced technology

Get Started

About Us

Offering assembly services from components to complete machines, covering various types of automated equipment, industrial robots, and production lines, ensuring equipment stability and

Get Started

2030.3-2016

Sep 30, 2016 · Applications of electric energy storage equipment and systems (ESS) for electric power systems (EPSs) are covered. Testing items and procedures, including type test,

Get Started

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

ETN News | Energy Storage News | Renewable

3 days ago · ETN news is the leading magazine which covers latest energy storage news, renewable energy news, latest hydrogen news and much more.

Get Started

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Introduction Energy storage market is on rise across the world. Every company, new or old, that is in the field of renewables or electric vehicles, is looking for even more

Get Started

What does energy storage equipment manufacturing include?

Oct 7, 2024 · Energy storage equipment manufacturing encompasses various components essential for the development, production, and deployment of systems that store energy. 1.

Get Started

Assembly line for battery modules and battery packs

6 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Get Started

Zinc-ion Battery Innovator Enerpoly Acquires Full Cell Production

Jul 15, 2024 · In the latest step towards establishing Europe as an energy storage powerhouse, Enerpoly''s integration of new production capabilities will further enhance its delivery of

Get Started

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Get Started

Energy Storage PCB Assembly Manufacturer | Inverter PCB Assembly

Watch on Energy Storage PCBA Manufacturer With over 15 years of PCBA experience, PCBasic delivers reliable energy storage PCB assembly with precision SMT, DIP, and full testing

Get Started

Eve Energy''s 60GWh Super Energy Storage Plant

Dec 13, 2024 · To solve the challenges that the size of large batteries poses to production lines and manufacturing processes, EVE Energy has specially built

Get Started

Energy Storage – FAPS – Institute for Factory Automation and Production

The research and development of a design suitable for disassembly, detachable contacting methods and automated disassembly processes are important for this. In the "Energy Storage"

Get Started

Factorial Energy Opens Solid-State Battery Plant,

Oct 24, 2023 · With A-Sample battery cells now rolling out to OEMs, Factorial has commenced production at a brand new facility in its home state – quite

Get Started

Energy S.p.A plans 8 GWh battery production

Apr 22, 2025 · Changing electrochemical energy storage regulations will dramatically increase the deployment of Italian BESS, Davide Tinazzi, CEO of

Get Started

Related Articles

-

Malawi medical equipment energy storage battery assembly

Malawi medical equipment energy storage battery assembly

-

Industrial and commercial energy storage cabinet production equipment

Industrial and commercial energy storage cabinet production equipment

-

Energy storage equipment production factory

Energy storage equipment production factory

-

Energy storage cabinet production equipment and price

Energy storage cabinet production equipment and price

-

Large-scale energy storage power station production equipment

Large-scale energy storage power station production equipment

-

Commercial energy storage production equipment

Commercial energy storage production equipment

-

What are the energy storage battery production equipment

What are the energy storage battery production equipment

-

What is energy storage power plant production equipment

What is energy storage power plant production equipment

-

Energy storage configuration outdoor cabinet packaging power equipment

Energy storage configuration outdoor cabinet packaging power equipment

-

What are the categories of energy storage equipment

What are the categories of energy storage equipment

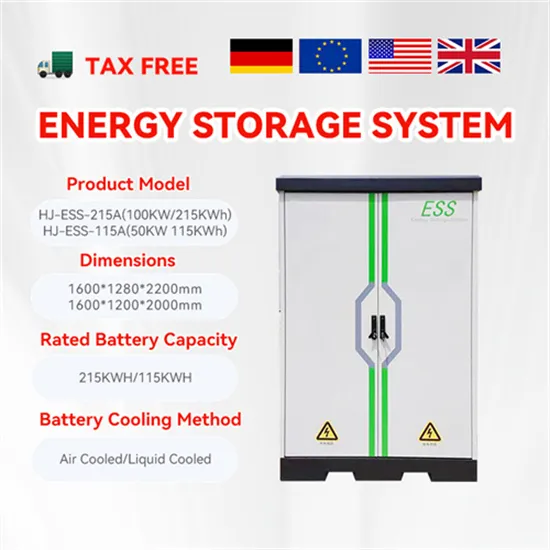

Commercial & Industrial Solar Storage Market Growth

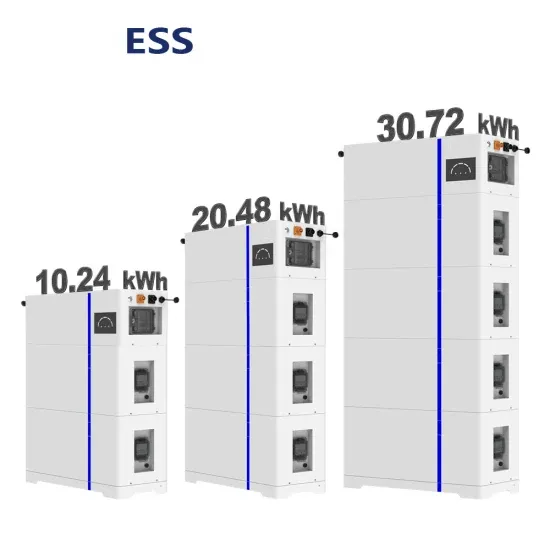

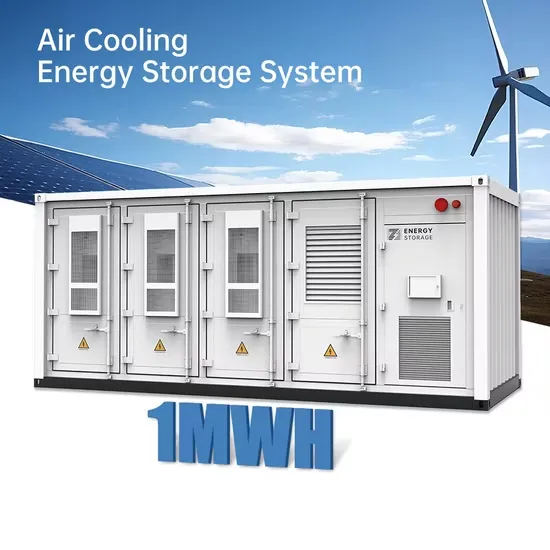

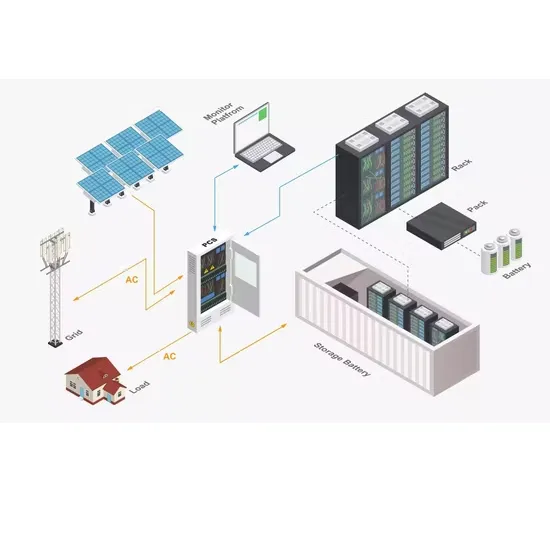

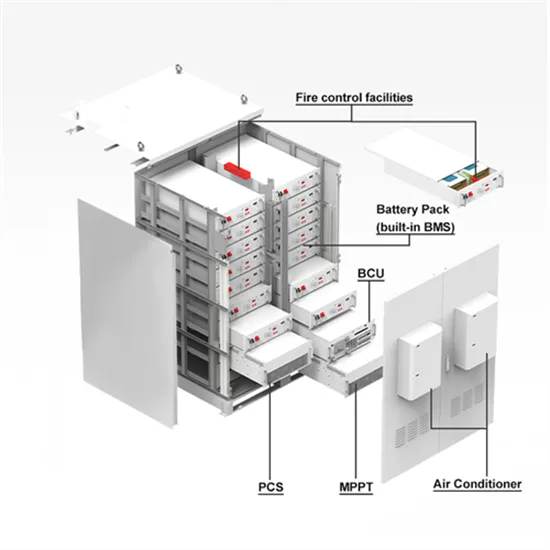

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

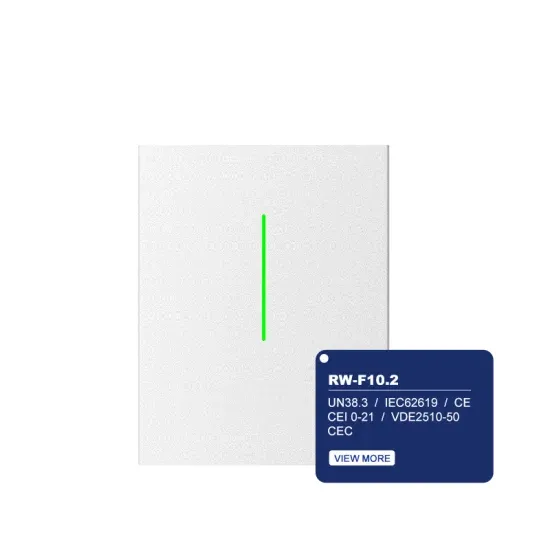

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.