5243-2025 预制舱式储能电站

Jun 18, 2025 · 预制舱式磷酸铁锂电池储能电站防火规范 Specification for fire protection of prefabricated cabin type lithium iron phosphate battery energy storage power station 2025 - 05

Get Started

预制舱式磷酸铁锂电池储能电站能耗计算研究

Mar 23, 2023 · 摘要: [目的]基于站内能量损耗来源和设备属性详细分类,提出了预制舱式磷酸铁锂电池储能电站能耗计算方法。 [方法]从储能电站的角度论述了预制舱式磷酸铁锂电池储能电站能

Get Started

Thermal runaway and explosion propagation

When the opening pressure of the cabin door increases from 10 to 100 kPa, the peak explosion overpressure increases by 2.15 times. This research can

Get Started

Fire Accident Simulation and Fire Emergency Technology

Sep 26, 2022 · In order to establish a reliable thermal runaway model of lithium battery, an updated dichotomy methodology is proposed-and used to revise the standard heat release

Get Started

Typical fire protection case of lithium iron phosphate battery energy

Jun 30, 2023 · Finally, based on the typical fire fighting system case of prefabricated cabin type lithium iron phosphate battery energy storage system in actual work, the system composition

Get Started

A Collaborative Design and Modularized

Apr 4, 2022 · Research in this paper can be guideline for breakthrough in the key technologies of enhancing the intrinsic safety of lithium-ion battery energy

Get Started

DB34T 5243-2025预制舱式磷酸铁锂电池储能电站防火规范

Jun 30, 2025 · ICS 13.220.20 CCS P 16 34 安 徽 省 地 方 标 准 DB34/T 5243—2025 预制舱式磷酸铁锂电池储能电站防火规范Specification for fire protection of prefabricated cabin type

Get Started

预制舱式磷酸铁锂电池储能电站防火规范(DB34-T 5243-2025)

Jul 1, 2025 · ICS 13.220.20 CCS P 16 34 安 徽 省 地 方 标 准 DB34/T 5243—2025 预制舱式磷酸铁锂电池储能电站防火规范Specification for fire protection of prefabricated cabin type lithium

Get Started

Shanghai Electric Gotion New Energy

Jun 8, 2022 · The energy storage power station adopts electrochemical energy storage technology and uses lithium iron phosphate batteries. The total

Get Started

What is a prefabricated cabin energy storage power station?

Jan 28, 2024 · The emergence of prefabricated cabin energy storage power stations signifies a significant advancement in energy management and sustainability practices. These systems

Get Started

Station-type energy storage cabin

Characteristics of station-type energy storage1. Centralized thermal management, reducing auxiliary power consumption and improving operating efficiency . 2. Easy operation and The

Get Started

fenrg-2022-846741 1..15

Mar 30, 2022 · With the motivation of electricity marketization, the demand for large-capacity electrochemical energy storage technology represented by prefabricated cabin energy storage

Get Started

Key aspects of a 5MWh+ energy storage system

3 days ago · More than a month ago, CATL''s 5MWh EnerD series liquid-cooled energy storage prefabricated cabin system took the lead in successfully

Get Started

Delving into the Fire Safety Standards for Prefabricated Cabin

Jun 16, 2025 · In the rapidly evolving world of energy storage technology, safety remains a paramount concern. The recently issued Jiangsu local standard, DB32-T4682-2024, Technical

Get Started

American energy storage prefabricated cabin

The invention provides a fire early warning method for a prefabricated battery compartment of a lithium iron phosphate energy storage power station, and relates to the field of fire fighting; a

Get Started

Simulation of thermal runaway gas explosion in double-layer

First, the double-layer structure prefabricated cabin energy storage is introduced; then, a simplified model of the double-layer prefabricated cabin energy-storage power station is

Get Started

预制舱式磷酸铁锂电池储能电站能耗计算研究

Mar 23, 2023 · Research on Energy Consumption Calculation of Prefabricated Cabin Type Lithium Iron Phosphate Battery Energy Storage Power Station LI Xuebin,ZHAO Hao,CHEN

Get Started

The first cabin structure''s concrete pouring for China''s

May 15, 2025 · The station includes 80 storage battery cabins with a capacity of 5 MWh each and 40 boost transformer prefabricated cabins with a capacity of 5 MW each. Additionally, a new

Get Started

Frontiers | A Collaborative Design and

Apr 4, 2022 · In order to solve the key technical problems that existing in large-capacity prefabricated cabin type energy storage, and meet the grid energy

Get Started

预制舱式磷酸铁锂电池储能电站防火设计

This paper analyzes and summarizes the characteristics of fire occurrence and development of prefabricated cabin type lithium iron phosphate battery energy storage power station through

Get Started

预制舱式磷酸铁锂电池储能电站能耗计算研究

LI Xuebin, ZHAO Hao, CHEN Shilong. Research on Energy Consumption Calculation of Prefabricated Cabin Type Lithium Iron Phosphate Battery

Get Started

Energy storage battery container prefabricated cabin

Apr 14, 2024 · Abstract: Prefabricated cabin type lithium iron phosphate battery energy storage power station is widely used in China, and its fire safety is the focus of attention at home and

Get Started

预制舱式磷酸铁锂电池储能电站能耗计算研究

Method From the perspective of an energy storage power station, this paper discussed the main factors to be considered in the energy consumption calculation of prefabricated cabin type

Get Started

prefabricated cabin energy storage power station

Fire design of prefabricated cabin type lithium iron phosphate This paper analyzes and summarizes the characteristics of fire occurrence and development of prefabricated cabin type

Get Started

Battery Energy Storage Container: Differences

Sep 12, 2023 · Applications: Versatility of Containers and Prefabricated Cabins Applications of Containers: Battery storage containers are suitable for various

Get Started

A Collaborative Design and Modularized

Apr 4, 2022 · It is necessary to develop a modularized and intelligent integration technology for cabin-type energy storge in MW ∼ GW for the deep

Get Started

Fire design of prefabricated cabin type lithium iron

Mar 15, 2021 · Abstract Abstract: Prefabricated cabin type lithium iron phosphate battery energy storage power station is widely used in China, and its fire safety is the focus of attention at

Get Started

energy storage power cabin

Prefabricated cabin lithium-ion battery energy storage power stations hold immense potential for revolutionizing the energy landscape. However, ensuring their safety is paramount.

Get Started

Prefabricated Energy Storage System Solution

Prefabricated energy storage systems are a commonly utilized configuration for large-scale energy storage projects, integrating features such as lithium iron phosphate battery packs for

Get Started

prefabricated energy storage cabin and power grid

A prefabricated cabin of an energy storage power station shutter is used for connecting an external energy storage power station, a load end and a power distribution network and

Get Started

Energy storage prefabricated cabin foundation

A pier and beam foundation is a popular and versatile type of foundation for a cabin. There are two type of pier and beam foundations. One is utilizing a cement pad on top of the soil acting

Get Started

the role of energy storage battery prefabricated cabin

Fire design of prefabricated cabin type lithium iron phosphate battery power station. ZHUO Ping1,2, GUO Peng-yu3, LU Shi-chang1,2, WU Jing-yun4. Abstract: Prefabricated cabin type

Get Started

6 FAQs about [Prefabricated cabin lithium battery energy storage power station]

How many MWh can a 20 ft battery storage system produce?

The DC sides of the battery clusters are connected in parallel and then connected to the DC side of the PCS. The energy of a single cabin can reach more than 5MWh. Compared with the mainstream 20-foot 3.72MWh energy storage system, the 20-foot 5MWh energy storage system has a 35% increase in system energy.

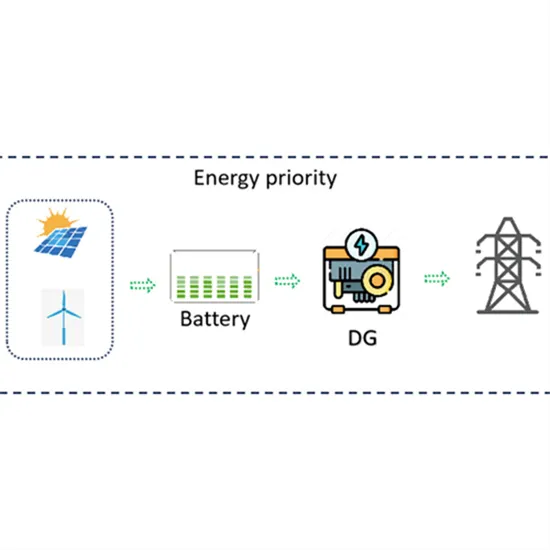

How can energy storage power stations reduce energy consumption?

Taking CATL’s “Ener Series” as an example, the energy of a single cabin has been increased from the existing 3.354MWh to 5.016MWh, and the energy density has been increased by about 50%. This can effectively save floor space and reduce the comprehensive investment cost and station power consumption of energy storage power stations.

How does a 5MWh+ battery cabin work?

According to industry experts, most of the 5MWh+ battery cabins adopt centralized topology and liquid cooling and heat management. There are 12 battery clusters in the whole cabin. The DC sides of the battery clusters are connected in parallel and then connected to the DC side of the PCS. The energy of a single cabin can reach more than 5MWh.

How much energy does a 280ah battery cabin use?

A 20-foot liquid-cooled battery cabin using 280Ah battery cells is installed. Each battery cabin is equipped with 8 to 10 battery clusters. The energy of a single cabin is about 3MWh-3.7MWh. You can click our liquid cooling vs air cooling to get more information about cooling.

Which China Top 10 energy storage system integrator has deployed 5MWh+ batteries?

In fact, with the release of 300Ah+ large-capacity battery cells, members of China top 10 energy storage system integrator have deployed 5MWh+ energy storage battery compartments, such as CATL, Sungrow, CRRC Zhuzhou Institute, TrinaStorage, etc.

What is 5MWh+ energy storage equipment?

5MWh+ energy storage equipment leads to the design of long modules and large packs. The larger packs pose greater challenges to the pack’s structural strength, heat dissipation temperature distribution, and safety design.

Related Articles

-

120W lithium battery energy storage power station

120W lithium battery energy storage power station

-

Does Türkiye have a lithium battery energy storage power station

Does Türkiye have a lithium battery energy storage power station

-

Lithium battery energy storage cost of energy storage power station

Lithium battery energy storage cost of energy storage power station

-

Benin Energy Storage Power Station Lithium Battery

Benin Energy Storage Power Station Lithium Battery

-

Lithium battery supply for Astana energy storage power station

Lithium battery supply for Astana energy storage power station

-

Lithium battery energy storage power station investment

Lithium battery energy storage power station investment

-

Can I buy the new energy storage base station power lithium battery

Can I buy the new energy storage base station power lithium battery

-

Quality inspection of lithium battery energy storage power station

Quality inspection of lithium battery energy storage power station

-

Burundi energy storage power station bans lithium batteries

Burundi energy storage power station bans lithium batteries

-

Taipei Energy Storage Station Lithium Iron Phosphate Battery

Taipei Energy Storage Station Lithium Iron Phosphate Battery

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.