The difference between frequency converter and

Apr 2, 2024 · The inverter with adjustable frequency and voltage of the inverter power supply is called a frequency converter. The waveform output by the

Get Started

Understanding High-Frequency Inverters

Aug 20, 2025 · Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression.

Get Started

High frequency off-grid inverter control

Dec 7, 2024 · High frequency off-grid inverter control Integrated machineIntroductionAn off-grid inverter system is a crucial component of

Get Started

Understanding the Difference Between Low Frequency and

May 15, 2024 · High frequency inverter: High frequency inverters use high-frequency switching technology to chop DC power at high frequency through

Get Started

Learn About High vs. Low Frequency Inverters:

Feb 10, 2025 · High-frequency inverters have a much higher internal switching frequency than conventional low-frequency inverters - typically 20 kHz to 100

Get Started

Inverter Welding Machines: The Ultimate Guide

Sep 9, 2024 · An inverter welding machine utilizes advanced electronic technology to convert incoming AC power into a high-frequency AC current, which is then rectified and filtered to

Get Started

High Frequency Inverter Schematic Circuits

Nov 14, 2020 · High Frequency Inverter Schematic CircuitsHigh frequency inverter schematic circuits are the key components of a wide range of

Get Started

High Frequency Inverter Circuit

Nov 19, 2019 · A high frequency inverter circuit is an electronic circuit that allows for the conversion of DC electricity into AC power with a high frequency, usually around 60 Hz or more.

Get Started

What is the difference between a low frequency inverter and a high

Feb 6, 2025 · High-Frequency Inverter: Operates at much higher frequencies, often reaching tens of kHz or even higher. This allows high-frequency inverters to use smaller magnetic

Get Started

Inversion Methods Explained: High Frequency vs Low Frequency

5 days ago · HF inverters have over twice the number of components and use multiple, smaller transformers. Their application is appropriate for a wide variety of uses like tool battery

Get Started

How to Distinguish High Frequency Inverter and Low Frequency Inverter

Apr 11, 2024 · Low frequency inverters produce less electromagnetic interference, but can only produce lower AC power frequencies, while high frequency inverters can produce higher

Get Started

High-Frequency Inverter: How They Work and

4 days ago · A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency,

Get Started

Inverter Welders Explained: What They Are and

1. What is the difference between an inverter welder and a transformer welder? Inverter welders use electronic circuitry to convert power at a high frequency,

Get Started

The difference between a high and low frequency inverter

High frequency inverters are compact and efficient, making them ideal for applications where space is limited, such as solar power systems and portable devices. Low frequency inverters

Get Started

What is a Frequency Inverter? A Complete Guide to How It

5 days ago · A frequency inverter is an electronic device that converts the fixed frequency and fixed voltage from your electrical supply (e.g.,50Hz or 60Hz,240V or 480V)into a variable

Get Started

6 FAQs about [Is a high frequency machine an inverter ]

What is a high frequency inverter?

The high frequency inverter converts DC power into AC power using electronic components, such as capacitors and inductors. The high frequency output of a high frequency inverter is ideal for powering electronic devices, such as computers and televisions. High frequency inverters typically have an output of 20kHz or higher.

Should I buy a high frequency inverter or low frequency?

If you need to power heavy-duty appliances, such as air conditioners and refrigerators, a low frequency inverter may be the best option. If you need to power electronic devices, such as computers and televisions, a high frequency inverter may be the better option.

How does a power frequency inverter work?

Its working principle is to convert DC power into AC power with the same frequency and phase as the power grid through an internal power conversion circuit. Power frequency inverters mostly use traditional components such as transformers and inductors to convert voltage and current.

What are the advantages of high frequency inverters?

Volume and weight: Since high frequency inverters use high-frequency switching technology and compact circuit design, their size and weight are usually much smaller than power frequency inverters. This gives high frequency inverters significant advantages in mobile power supplies, aerospace, electric vehicles, and other fields.

How do high-frequency inverters work?

These enigmatic devices possess the uncanny ability to transform direct current (DC) into alternating current (AC) at remarkably high frequencies, unlocking a world of boundless possibilities. This comprehensive guide embarks on a quest to unravel the intricacies of high-frequency inverters, peeling back their layers to reveal their inner workings.

Are power frequency inverters good?

In contrast, power frequency inverters can maintain high efficiency and stability under heavy load or overload. Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters.

Related Articles

-

Is a high frequency machine an inverter

Is a high frequency machine an inverter

-

High frequency inverter in Douala Cameroon

High frequency inverter in Douala Cameroon

-

Argentina high frequency inverter manufacturer

Argentina high frequency inverter manufacturer

-

High frequency inverter 100w

High frequency inverter 100w

-

High frequency inverter has high temperature

High frequency inverter has high temperature

-

Algeria High Frequency Inverter

Algeria High Frequency Inverter

-

High Frequency Inverter Manufacturer in Lagos Nigeria

High Frequency Inverter Manufacturer in Lagos Nigeria

-

Iraq high frequency inverter device manufacturer

Iraq high frequency inverter device manufacturer

-

Papua New Guinea high frequency inverter price

Papua New Guinea high frequency inverter price

-

Armenia high frequency sine wave inverter

Armenia high frequency sine wave inverter

Commercial & Industrial Solar Storage Market Growth

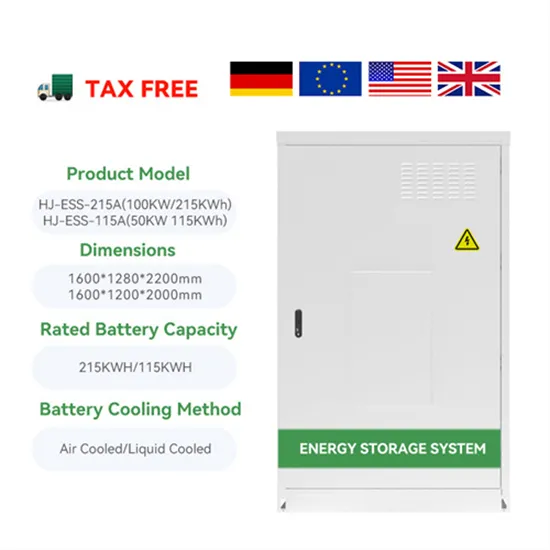

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.