NMC Power Battery Pack-Next Generation Energy Tech. Co.,

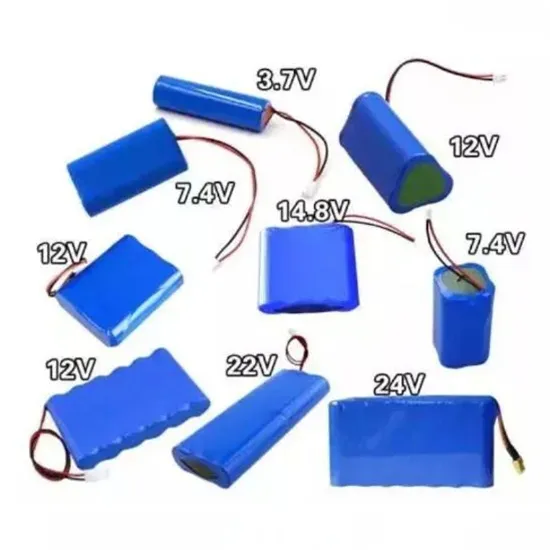

High performance Lithium-Ion NMC battery pack, with a built in battery management system (BMS). Drop-in fitment, enables seamless battery pack installation, providing a direct

Get Started

Optimization Analysis of Power Battery Pack Box

Mar 9, 2023 · The power battery pack module of the target model is composed of 288 single cells, every 12 single cells are combined into an independent battery module in parallel, and a total

Get Started

The 3rd China New Energy Vehicle Battery

With the continuous development of material science and chemical engineering, new materials and structural design will further improve the energy density of

Get Started

Battery Pack & Configuration

Dec 31, 2024 · Battery Pack & Configuration The battery system combines many cells and other control electronics into a full battery to power the EV.

Get Started

EV Battery Pack Design: Structure, Safety

Oct 4, 2024 · The electric vehicle''s power source is the battery pack, of which the battery cell is the smallest component. Currently, the market is dominated by

Get Started

EVs Battery Pack Technology Today and

Oct 12, 2023 · In this blog, we''ll explore the latest advancements in EV battery pack technology and investigate future development trends that are driving the

Get Started

2025 New Energy Battery Module Technology

May 29, 2025 · New energy battery modules, as the core components of new energy vehicles and energy storage systems, directly determine range, safety,

Get Started

Simulation and optimization of a new energy

Aug 26, 2021 · Comparing with traditional vehicles, the new energy vehicles industry should pay more attention to safety of power battery pack structures.

Get Started

New Energy Automation

1 day ago · The FHS power battery module PACK production line offers a complete range of product categories, including CTP series power battery

Get Started

Battery Lab Making Machine,Battery Pack

This lithium ion battery pack assembly line is specifically designed for the manufacturing of battery modules used in electric two wheeler, electric three

Get Started

SIMULATION AND OPTIMIZATION OF A NEW ENERGY

Jan 13, 2024 · With the rapid growth in new energy vehicle industry, more and more new energy vehicle battery packs catch fire or even explode due to the internal short circuit. Comparing with...

Get Started

Lithium-Ion Battery Charging Module Supplier

The Soundon New Energy battery module serves various functions across multiple applications. It is used in electric vehicles, energy storage systems, and uninterruptible power supplies.

Get Started

Research and Application of Flexible Manufacturing Line for Power

Sep 1, 2021 · At present, due to the lack of national mandatory new energy vehicle power battery pack specifications and standards, so each production enterprise is fighting for itself, the size,

Get Started

Sturcture of Battery: From Cell to Module and

Apr 21, 2025 · The Structure of a Battery To review a battery''s structure from a macro-view as a whole pack until the smallest units, which are referred to as

Get Started

[电池扫盲]一文带小白了解电芯(cell),电池模块

Jun 18, 2023 · 随着近几年电动车市场以及储能市场的火热,越来越多的小伙伴加入了电池行业。对于刚入行的小白以及由学术界转入工业界的朋友,难免会对

Get Started

Explore new energy vehicles:Cells, modules and

Mar 20, 2025 · Unlock the secrets of new energy vehicles! Explore how battery cells, modules, and packs power performance, with insights from Guheng

Get Started

Pack/Module EOL Integrated Testing System

Aug 16, 2025 · Pack/Module EOL Integrated Testing System - EST group is a national high-tech enterprise that provides full industry supply chain services for the new energy battery industry.

Get Started

Structural Analysis of Battery Pack Box for New

Oct 1, 2022 · The box structure of the power battery pack is an important issue to ensure the safe driving of new energy vehicles, which required relatively better

Get Started

Lithium Battery Module Pack Assembly Line

A Lithium Battery Module PACK Assembly Line is a production line designed to assemble individual lithium battery cells into modules and then further assemble these modules into

Get Started

Optimization and Structural Analysis of

Nov 4, 2024 · The development of new energy vehicles, particularly electric vehicles, is robust, with the power battery pack being a core component of the

Get Started

Enabling New EV Battery Chemistries Through Battery Pack

Jan 7, 2025 · Regardless of the cell-to-pack approach, automakers have been reducing the amount of materials that are used around the battery cells in a bid to increase pack energy

Get Started

EV Battery Pack Design: Structure, Safety

Oct 4, 2024 · Explore structural design and optimization of new energy vehicle battery packs for improved range, safety, and performance.

Get Started

Explore new energy vehicles:Cells, modules and

Mar 20, 2025 · Battery Module: It is composed of multiple units and provides modular management. Battery Pack: A collection of modules, integrated into

Get Started

BATTERT PACK & MODULE ASSEMBLY

New energy battery Pack assembly test line Whole Machine Features: Processing the battery cell first, then put into the pack box The whole line of

Get Started

Battery Cell VS Battery Module VS Battery Pack

Understanding the differences between battery cells, modules, and packs is essential for designing efficient energy storage systems. This article examines

Get Started

New Energy Battery Module Pack Assembly Line | SENFENG

New Energy Battery Module Pack Assembly Line This module pack assembly line is modular-based and compact in structure. Due to its intelligent management, it is totally traceable.

Get Started

Sparking a Second Life of Power Battery PART 3.

Battery pack designs, module connection method and processing technologies differ from modules and battery types, which means that it is impossible to use

Get Started

The Modular Lithium Battery System:

Aug 15, 2025 · Discover The modular Lithium battery system : PowerModule for mid and heavy duty traction, robotics, ESS, and high-capacity applications.

Get Started

10 Most Energy-Efficient Battery Technology For

Mar 7, 2025 · During the initial adoption of power batteries in new energy vehicles, the absence of a unified standard resulted in a wide variety of

Get Started

EVEV Solutions

EV Diagnosis Add-on Kit EV Solutions for Maintenance & Detection LAUNCH New Energy Battery Pack Diagnostic Upgrade Kit comes with battery pack testing cables for various vehicle

Get Started

Battery Cell VS Battery Module VS Battery Pack

Mar 5, 2024 · A battery pack, also known as a battery pack or battery assembly, comprises one or more battery modules or cells arranged in series or parallel

Get Started

6 FAQs about [New energy battery pack module]

What is FHS power battery module pack?

The FHS power battery module PACK production line offers a complete range of product categories, including CTP series power battery module pack intelligent manufacturing solutions, blade power battery module pack intelligent manufacturing solutions, and CTC series intelligent manufacturing solutions.

Can a modular cooling system support the design of a battery pack?

Cicconi et al. (2020) proposed a modular approach to support the design of a battery pack consider-ing Phase-Change Materials in the cooling system, and showed how a single module of cells could be stacked and how the cooling system of each module could be easily connected to each other.

How is the battery pack of a new energy vehicle simulated?

In this paper, the battery pack of a new energy vehicle is studied, modeled and simulated by the finite element method. Hypermesh, ANSYS and other simulation analysis software are used to analyze the static strength and dynamic modal properties.

How important is a battery pack for a new energy vehicle?

For new energy vehicles, the key component that affects vehicle safety is the battery pack. As the carrier of the battery, the importance of the battery pack cannot be underestimated. The strength, rigidity, heat dissipation and waterproof of the battery pack body should meet high design requirements (Feng and Hu, 2020).

What are the components of a battery pack?

The main components of the battery pack have six parts. The outside is composed of the housing upper cover, the housing base and the lug connecting pieces. The upper cover and the base are connected by bolts, and the inside is composed of battery modules, fixing plates of battery modules and high liquid cooling plates, etc.

What is a high performance lithium-ion NMC battery pack?

High performance Lithium-Ion NMC battery pack, with a built in battery management system (BMS). Drop-in fitment, enables seamless battery pack installation, providing a direct replacement solution with precise compatibility and minimal modifications to the existing mounting system.

Related Articles

-

New energy vehicle power battery pack price

New energy vehicle power battery pack price

-

New Energy 21V Lithium Battery Pack New Energy

New Energy 21V Lithium Battery Pack New Energy

-

Pack battery factory new energy vehicles

Pack battery factory new energy vehicles

-

Kathmandu New Energy EK Energy Storage Battery

Kathmandu New Energy EK Energy Storage Battery

-

150ah energy storage battery pack price

150ah energy storage battery pack price

-

Can the energy storage cabinet battery be made into a battery pack

Can the energy storage cabinet battery be made into a battery pack

-

New energy plus battery cabinet plus insurance

New energy plus battery cabinet plus insurance

-

How to charge the new energy battery cabinet in Papua New Guinea

How to charge the new energy battery cabinet in Papua New Guinea

-

Nicosia new energy lithium battery bms structure

Nicosia new energy lithium battery bms structure

-

Comparison of domestic new energy battery cabinets

Comparison of domestic new energy battery cabinets

Commercial & Industrial Solar Storage Market Growth

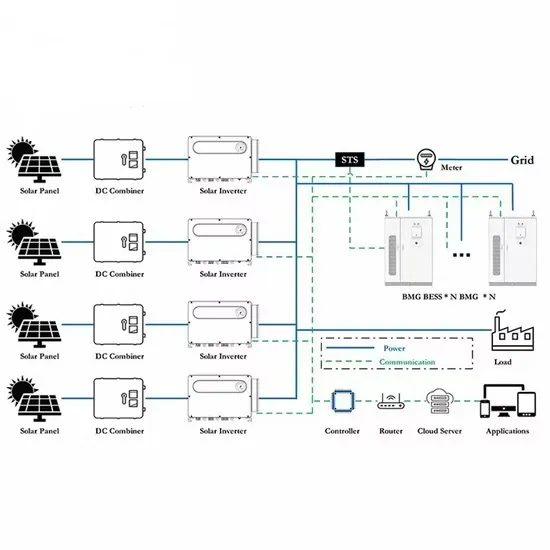

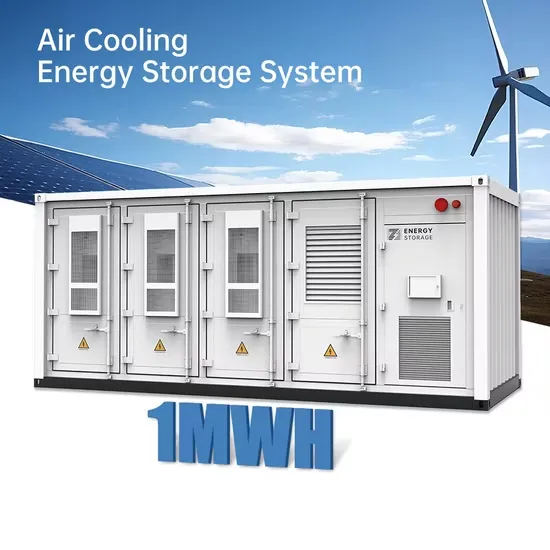

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.