Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Jul 7, 2025 · 1. Short heat dissipation path, precise temperature control Liquid-cooled systems utilize a CDU (cooling distribution unit) to directly introduce low-temperature coolant into the

Get Started

Optimization of data-center immersion cooling using liquid air energy

Jun 15, 2024 · A mathematical model of data-center immersion cooling using liquid air energy storage is developed to investigate its thermodynamic and economic performance.

Get Started

Exploration on the liquid-based energy storage battery system

Dec 1, 2024 · Lithium-ion batteries are increasingly employed for energy storage systems, yet their applications still face thermal instability and safety issues. This study aims to develop an

Get Started

Energy Storage System Cooling

May 5, 2025 · Depending on the location of the base station, temperatures may range from a high of 50°C to a low of -30°C. The heat generated within the battery cabinet can vary depending

Get Started

Thermal Management Technology of 1MWh BESS Energy Storage System

Dec 27, 2024 · The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

Get Started

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit,

Get Started

Two-phase immersion liquid cooling system for 4680 Li-ion

Sep 10, 2024 · The results indicate that the utilization of two-phase immersion cooling system proved highly efficient in maintaining the cell temperature within the range of 34–35 °C across

Get Started

Liquid-cooling becomes preferred BESS

Jan 21, 2025 · As the industry gets more comfortable with how lithium batteries interact in enclosed spaces, large-scale energy storage system engineers are

Get Started

Thermal management solutions for battery

Jul 25, 2023 · Listen this articleStopPauseResume This article explores how implementing battery energy storage systems (BESS) has revolutionised

Get Started

Liquid cooling design requirements for energy storage

A liquid air-based cooling system applied in data centers should not only meet the maximum cooling requirements of data center but also demonstrate good performance two types of

Get Started

Proceedings of

Oct 31, 2024 · ABSTRACT The lifetime and performance of battery energy storage system depend on the temperature uniformity between batteries. In order to meet the temperature

Get Started

What is Immersion Liquid Cooling Technology in Energy Storage

Dec 11, 2024 · Immersion liquid cooling technology is an efficient method for managing heat in energy storage systems, improving performance, reliability, and space efficiency.

Get Started

Liquid-Cooled Energy Storage System

As the demand for high-capacity, high-power density energy storage grows, liquid-cooled energy storage is becoming an industry trend. Liquid-cooled

Get Started

6 Low-temperature thermal energy storage

Sensible storage of heat and cooling uses a liquid or solid storage medium witht high heat capacity, for example, water or rock. Latent storage uses the phase change of a material to

Get Started

Battery Energy Storage

Active water cooling is the best thermal management method to improve battery pack performance. It is because liquid cooling enables cells to have a more uniform temperature

Get Started

Research on the optimization control strategy of a battery

Feb 28, 2025 · The thermal performance of the system was evaluated through experimental and simulation analyses across various operating conditions and configurations. Results

Get Started

Integrated cooling system with multiple operating modes for temperature

Apr 15, 2025 · Aiming at the problem of insufficient energy saving potential of the existing energy storage liquid cooled air conditioning system, this paper integrates vapor compression

Get Started

Principles of liquid cooling pipeline design

3 days ago · This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection

Get Started

Thermodynamic and economic analyses of liquid air energy storage

Apr 1, 2025 · Moreover, the results indicate that the minimum cost of cold thermal energy storage is 7.4 M€ for the system with quartz as storing material with 24 packed bed tanks. These

Get Started

Field investigation on the performance of a novel hybrid cooling system

Traditional liquid cooling systems of containerized battery energy storage power stations cannot effectively utilize natural cold sources and have poor temperature uniformity. To address these

Get Started

Review on operation control of cold thermal energy storage in cooling

Jun 1, 2025 · Firstly, the composition and principles of cooling systems coupled with CTES are presented. Special attention was paid to cold storage medium of phase change material

Get Started

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Liquid cooling''s rising presence in industrial and commercial energy storage reflects an overall trend toward efficiency, safety, and

Get Started

Field study on the temperature uniformity of containerized

Feb 1, 2025 · The conventional liquid cooling system carries the risk of dew condensation and air cooling has poor thermal management performance for battery energy storage systems. To

Get Started

Thermal Management of Liquid-Cooled Energy

Dec 13, 2024 · However, the normal operating temperature of lithium batteries is between -20~50°C, and the comfortable charging temperature range is

Get Started

What is the temperature range of liquid-cooled energy storage?

Jan 12, 2024 · The temperature range for liquid-cooled energy storage systems is typically between -20°C and 60°C, with optimally functioning systems operating around 0°C to 35°C,

Get Started

LIQUID COOLING SOLUTIONS For Battery Energy

Aug 3, 2022 · LIQUID COOLING SOLUTIONS For Battery Energy Storage Systems or operating networks and systems for the Energy industry? If so, consider building t Thermal management

Get Started

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

Get Started

Liquid Cooling System Design, Calculation, and

Aug 19, 2025 · Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal

Get Started

Experimental assessment and comparison of single-phase

Nov 30, 2023 · In summary, the above assessment and comparison suggest that, in the indirect contact mode, the single-phase liquid cooling system with copper foam (SFLC-CF) has the

Get Started

Performance optimization of server water cooling system

Dec 1, 2021 · Finally, the operating conditions of the cooling water were optimized by minimizing the energy consumption of the water-cooled system. In addition, the factors of different safety

Get Started

How liquid-cooled technology unlocks the

There are numerous causes of thermal runaway, including internal cell defects, faulty battery management systems, and environmental contamination. Liquid

Get Started

What Is ESS Liquid Cooling?

2 days ago · Discover the advantages of ESS liquid cooling in energy storage systems. Learn how liquid cooling enhances thermal management, improves efficiency, and extends the lifespan of

Get Started

6 FAQs about [Minimum temperature of energy storage liquid cooling system]

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

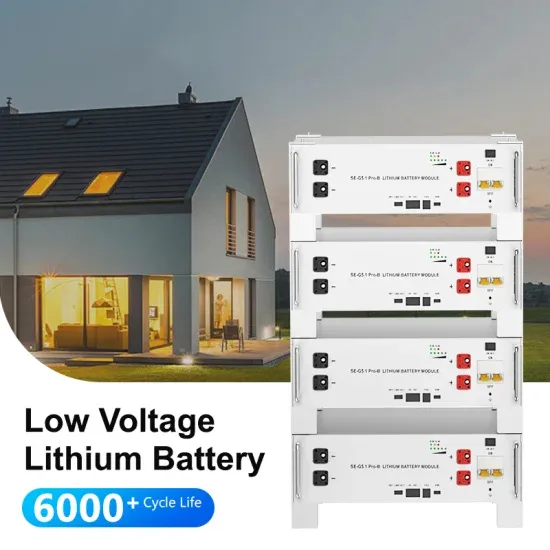

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

What is the operating range of a thermoelectric cooler?

For compressor-based systems, the typical operating range is +20 ̊C to +55 ̊C, allowing thermoelectric coolers to operate in a much larger environmental area. Thermoelectric cooler assemblies feature a solid-state construction, so they do not have compressors or motors.

Related Articles

-

What is the temperature of the energy storage cabinet liquid cooling cabinet

What is the temperature of the energy storage cabinet liquid cooling cabinet

-

Liquid cooling of energy storage battery cabinet

Liquid cooling of energy storage battery cabinet

-

Luxembourg 210 degree liquid cooling energy storage cabinet foreign trade

Luxembourg 210 degree liquid cooling energy storage cabinet foreign trade

-

Liquid Cooling Energy Storage System

Liquid Cooling Energy Storage System

-

Vienna liquid cooling energy storage container installation

Vienna liquid cooling energy storage container installation

-

The prospects of liquid cooling energy storage in Naypyidaw

The prospects of liquid cooling energy storage in Naypyidaw

-

Huawei Liquid Cooling Energy Storage in Dubai UAE

Huawei Liquid Cooling Energy Storage in Dubai UAE

-

Liquid Cooling Energy Storage Cabinet Configuration

Liquid Cooling Energy Storage Cabinet Configuration

-

Dubai Liquid Cooling Energy Storage Container Selling Price

Dubai Liquid Cooling Energy Storage Container Selling Price

-

Sierra Leone Energy Storage Container Liquid Cooling System

Sierra Leone Energy Storage Container Liquid Cooling System

Commercial & Industrial Solar Storage Market Growth

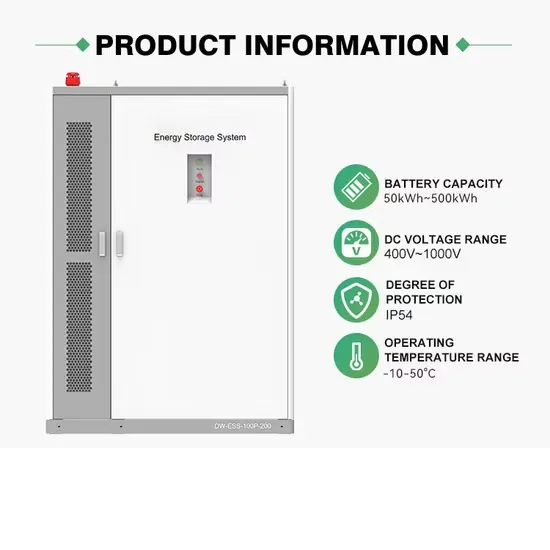

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.