Multi-objective topology optimization design of liquid-based cooling

Feb 1, 2025 · Developing energy storage system based on lithium-ion batteries has become a promising route to mitigate the intermittency of renewable energies and improve their

Get Started

Air and Liquid Cooling Solar Energy Battery storage System

May 23, 2025 · Energy storage temperature control is mainly based on air cooling and liquid cooling. We mainly compare the two from four aspects: battery pack temperature, operating

Get Started

Liquid cooling vs air cooling

Aug 24, 2023 · Temperature has an impact on the performance of the electrochemical energy storage system, such as capacity, safety, and life, so

Get Started

Air Cooling vs. Liquid Cooling of BESS: Which One Should

Aug 15, 2024 · When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling

Get Started

Thermal Management for Energy Storage: Air or

Dec 9, 2024 · Choosing the right cooling technology for Battery Energy Storage Systems (BESS) is crucial for performance and longevity. Explore air vs. liquid

Get Started

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · Although many EV OEMs use liquid cooling as the primary cooling method for their EV battery packages, the air-cooling BTMS is still well adopted in large-scale commercial

Get Started

Air and Liquid Cooling Solar Energy Battery storage System

May 23, 2025 · Comparison of Operating Energy Consumption Between Air Cooling and Liquid Cooling Energy storage temperature control is mainly based on air cooling and liquid cooling.

Get Started

Thermal Management for Energy Storage: Air or

Dec 9, 2024 · Choosing the right cooling technology is a critical decision, with air and liquid cooling being the dominant options. Each comes with its unique

Get Started

Difference Between Liquid and Air Cooling for

Jan 24, 2025 · Discover the key differences between liquid and air cooling for energy storage systems. Learn how each method impacts battery

Get Started

Liquid cooling vs air cooling

Aug 24, 2023 · Liquid cooling vs air cooling technology have their own advantages and disadvantages, and are also suitable for different application scenarios. 1. What is liquid

Get Started

An optimization study on the performance of air-cooling

Jul 1, 2025 · To provide a reference for the optimized design of air-cooling system for energy storage battery packs, and to promote the development and application of thermoelectric

Get Started

Eight Key Differences Between Air Cooling and

Aug 19, 2025 · Liquid cooling systems are also applicable to energy storage systems of diverse scales and types, but they excel in large-scale, high

Get Started

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Air cooling sis suitable for low-C-rate or cost-sensitive systems, while liquid cooling is for high-performance EVs and utility-scale storage

Get Started

A novel battery thermal management system with air–liquid

Jul 15, 2025 · Considering the low heat transfer efficiency of air cooling and the high energy loss of liquid cooling, a novel battery thermal management system (BTMS) coupled forced air

Get Started

A review of battery thermal management systems using liquid cooling

Jan 15, 2024 · Thermal management technologies for lithium-ion batteries primarily encompass air cooling, liquid cooling, heat pipe cooling, and PCM cooling. Air cooling, the earliest

Get Started

Evaluation of a novel indirect liquid-cooling system for energy storage

Feb 15, 2025 · Higher cooling water flow velocity and lower cooling temperature are beneficial for the temperature uniformity of battery pack, with a cooling temperature controlled below 35 °C.

Get Started

Advances in battery thermal management: Current

Aug 1, 2024 · A variety of thermal management techniques are reviewed, including air cooling, liquid cooling, and phase change material (PCM) cooling methods, along with their practical

Get Started

Cooling the Future: Liquid Cooling

Sep 27, 2023 · MeritSun, as a leading lithium battery manufacturer in the industry, employs reliable liquid cooling systems in their commercial and industrial

Get Started

Liquid Cooling in Energy Storage: Innovative Power Solutions

Jul 29, 2024 · Liquid cooling systems use a liquid coolant, typically water or a specialized coolant fluid, to absorb and dissipate heat from the energy storage components. The coolant circulates

Get Started

InnoChill''s Liquid Cooling Solution:

Dec 20, 2024 · Discover how InnoChill''s liquid cooling solution is transforming energy storage systems with superior heat dissipation, improved battery life,

Get Started

Energy storage cooling system

Dec 8, 2024 · Compared with air-cooled systems, liquid cooling systems for electrochemical storage power plants have the following advantages: small footprint, high operating efficiency,

Get Started

Optimized thermal management of a battery energy-storage

Jan 1, 2023 · For various cooling strategies of the battery thermal management, the air-cooling of a battery receives tremendous awareness because of its simplicity and robustness as a

Get Started

A review on the liquid cooling thermal management system

Dec 1, 2024 · Liquid cooling provides up to 3500 times the efficiency of air cooling, resulting in saving up to 40% of energy; liquid cooling without a blower reduces noise levels and is more

Get Started

Liquid Cooling in Energy Storage | EB BLOG

Oct 22, 2024 · Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance

Get Started

A comparative study between air cooling and liquid cooling

Nov 5, 2021 · The parasitic power consumption of the battery thermal management systems is a crucial factor that affects the specific energy of the battery pack. In this paper, a comparative

Get Started

Air Cooling vs. Liquid Cooling: Why Liquid

Feb 8, 2025 · With its superior thermal performance, enhanced energy efficiency, and improved battery longevity, liquid cooling is rapidly becoming the

Get Started

CHOOSING BETWEEN AIR-COOLED AND LIQUID

Jun 8, 2023 · Choosing between air-cooled and liquid-cooled energy storage requires a comprehensive evaluation of cooling requirements, cost

Get Started

Cabinet Air Conditioner for Battery Energy

Aug 19, 2025 · Applications Our Battery Energy Storage System (BESS) Liquid & Air Cooling Solutions are designed for a wide range of applications, ensuring

Get Started

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which Cooling

Jul 23, 2025 · Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance,

Get Started

THERMAL MANAGEMENT FOR ENERGY

Apr 2, 2023 · To maintain the temperature within the container at the normal operating temperature of the battery, current energy storage containers have

Get Started

2.5MW/5MWh Liquid-cooling Energy Storage System

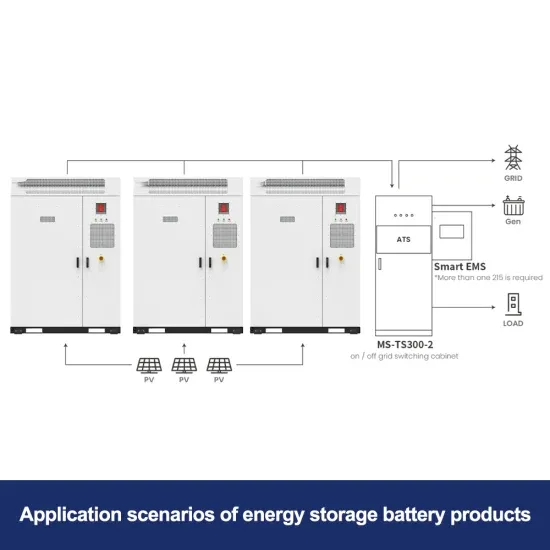

Oct 29, 2024 · 2 Energy Storage System Project 2.1 System Introduction The 2.5MW/5.016MWh battery compartment utilizes a battery cluster with a rated voltage of 1331.2V DC and a design

Get Started

6 FAQs about [Energy storage battery air cooling and liquid cooling]

Which cooling method is best for battery energy storage systems?

When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling and liquid cooling. Each method has its own strengths and weaknesses, making the choice between the two a critical decision for anyone involved in energy storage solutions.

What is an air cooled battery system?

Air-cooled systems use ambient air flow – fans or natural convection – to carry heat away from the cells. They are simple and low-cost, since no coolant, plumbing or pumps are needed. Air cooling avoids leak hazards and extra weight of liquids. As a result, smaller or lower-power battery installations often rely on air-cooled designs.

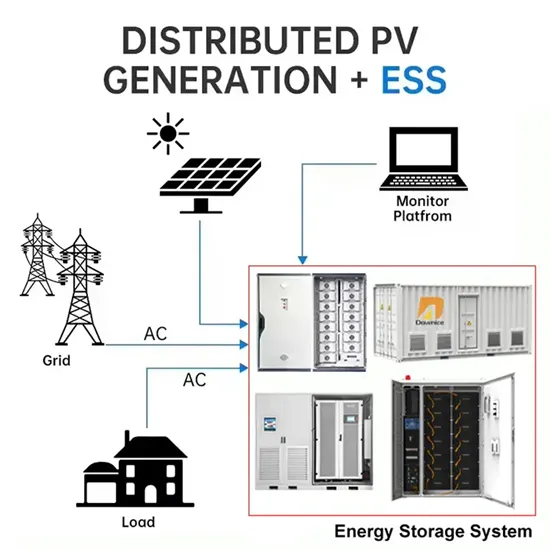

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) are essential for storing energy and ensuring its availability when needed. However, like all electronic systems, batteries generate heat during operation, especially when discharging or charging at high rates. Effective cooling is crucial to maintain the efficiency, safety, and longevity of these systems.

Is liquid-based cooling a viable alternative to forced-air cooling for EV batteries?

As one industry review notes that liquid-based cooling for EV batteries is the technology of choice, which is rapidly taking over from forced-air cooling, as energy and power densities increase. For instance, Tesla’s battery packs circulate a 50/50 ethylene glycol–water mix to cool cells.

How to cool a lithium ion battery?

Air cooling of lithium-ion batteries is achieved by two main methods: Natural Convection Cooling: This method utilises natural air flow for heat dissipation purposes. It is a passive system where ambient air circulates around the battery pack, absorbing and carrying away the heat generated by the battery.

How can a battery pack be cooled?

For example, having inlets and outlets at each end of the battery pack can promote a more uniform air path, thereby effectively cooling the entire battery pack. Adjusting the spacing between battery cells promotes optimal airflow and ensures even cooling of each battery cell.

Related Articles

-

Liquid cooling of energy storage battery cabinet

Liquid cooling of energy storage battery cabinet

-

Liquid Cooling Energy Storage Self-service Battery Cabinet

Liquid Cooling Energy Storage Self-service Battery Cabinet

-

New energy liquid cooling energy storage battery cabinet 80 degrees

New energy liquid cooling energy storage battery cabinet 80 degrees

-

Overseas Liquid Cooling Energy Storage

Overseas Liquid Cooling Energy Storage

-

Energy storage battery air duct

Energy storage battery air duct

-

Ranking of Liquid Cooling Energy Storage Cabinet Companies in South America

Ranking of Liquid Cooling Energy Storage Cabinet Companies in South America

-

Vanadium full liquid flow battery energy storage project

Vanadium full liquid flow battery energy storage project

-

Sierra Leone Energy Storage Container Liquid Cooling System

Sierra Leone Energy Storage Container Liquid Cooling System

-

Liquid cooling energy storage construction in Mombasa Kenya

Liquid cooling energy storage construction in Mombasa Kenya

-

Bogota Liquid Cooling Energy Storage Solution

Bogota Liquid Cooling Energy Storage Solution

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.