Advances in Multimaterial EV Battery Enclosures

Nov 15, 2021 · Evolving vehicle architectures make composites an attractive material choice for the enclosures of future EVs. The average enclosure weighs 80-150 kg. Complexity in design

Get Started

Battle for the EV Battery Box

Mar 17, 2023 · EV battery enclosures are a hotbed of subsystem design, materials innovation, and vehicle integration. Whether you call them packs, boxes, or trays, the structures that

Get Started

Why Energy Storage Station Chassis Design Is the Backbone

If you''re an engineer, project manager, or renewable energy enthusiast, you''ve probably wondered: "What makes large-scale energy storage systems tick?" Spoiler alert—it''s not just

Get Started

23.custom New Energy Battery Chassis Sheet Metal Parts

23.custom New Energy Battery Chassis Sheet Metal Parts Factory Processing-laser Cutting Bending Baking Paint, Find Complete Details about 23.custom New Energy Battery Chassis

Get Started

New Energy Storage Cabinet Shell Materials: The Unsung Heroes of Power

Jul 1, 2025 · From scorching desert solar farms to humid coastal wind parks, new energy storage cabinet shell materials work overtime to protect those precious lithium-ion batteries. EV

Get Started

Battery Cabinet Composite Materials | HuiJue Group E-Site

As global energy storage deployments surge past 120 GW capacity, battery cabinet composite materials have become the linchpin preventing thermal runaway. Did you know 63% of ESS

Get Started

Cell-to-Chassis Architecture in EVs | Optimizing

The Bedrock cell-to-chassis architecture (Image courtesy of CATL) Cell-to-chassis architecture Moving to cell-to-chassis architecture means significant

Get Started

Innovative Technology

6 days ago · Cell to chassis (CTC) technology integrates the battery cell with the vehicle body, chassis, electric drive, thermal management as well as various

Get Started

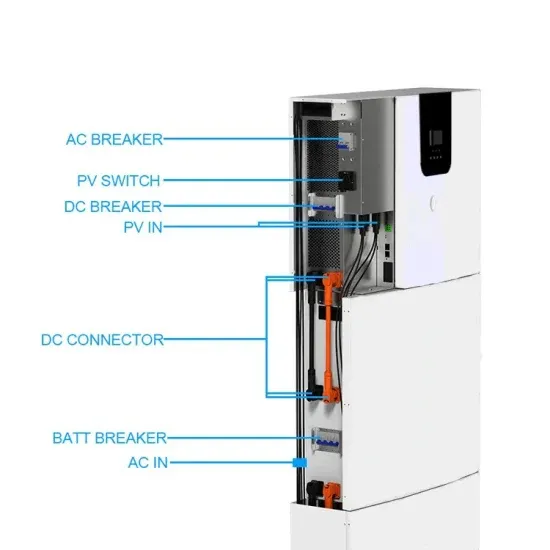

Energy Storage Chassis Wiring: Best Practices for Efficiency

Dec 28, 2024 · The 3-Pronged Challenge of Modern Energy Storage Wiring 1. Space vs. Safety: A Tightrope Walk Modern energy storage chassis pack more power than a Tesla battery pack

Get Started

Structural composition of energy storage cabinet

cabinet for your renewable energy storage needs. Telecom Infrastructure Sabre Industries manufactures thousands of telecommunications towers every year, and upgrad structural

Get Started

BAITU energy storage system-Hydrogen fuel

Guangzhou Baitu New Energy Battery Material Technology Co., Ltd. focuses on lithium-ion batteries energy storage system, Providing one-stop lithium-ion

Get Started

Aluminum profile chassis shell new energy battery aluminum

Aluminum Profile Chassis Shell New Energy Battery Aluminum Shell, Find Complete Details about Aluminum Profile Chassis Shell New Energy Battery Aluminum Shell,Waterproof Black

Get Started

What''s New in Battery Technology 2025

Feb 12, 2025 · The battery revolution is accelerating, driven by rapid advancements in energy density, charging speed, and material sustainability.

Get Started

New Energy Battery Housing Price | Supplier & Manufacturer

New Energy Battery Housing made of 3003 material is an aluminum alloy shell, ideally suited for users requiring durable, corrosion - resistant battery enclosures, such as in energy storage

Get Started

Energy Storage Chassis Standards: What You Need to Know

May 14, 2025 · Why Energy Storage Chassis Standards Matter More Than Ever Let''s face it – energy storage systems aren''t exactly lightweights. These workhorses of the renewable

Get Started

New Energy Battery Box Precision Sheet Metal Processing Home Energy

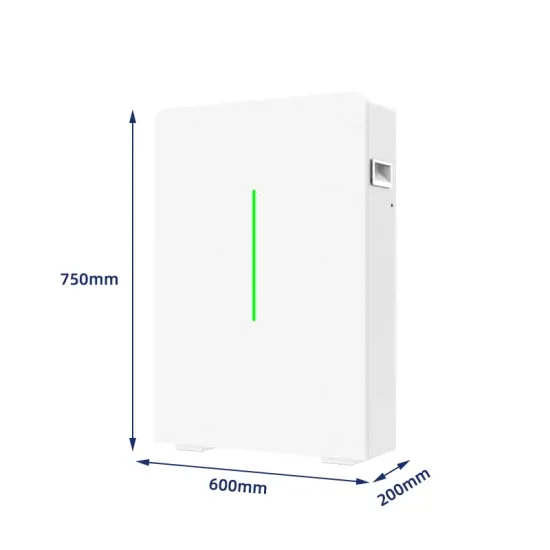

Nov 2, 2024 · New Energy Battery Box Precision Sheet Metal Processing Home Energy Storage Chassis Shell Sheet Metal Processing Finetight Sheet Metal, Find Details and Price about

Get Started

Home Energy Storage Chassis Production: Powering the

Mar 29, 2022 · Let''s be real—when''s the last time you thought about the metal skeleton holding your home battery system together? If you''re like most people, "home energy storage chassis

Get Started

How about new energy storage cabinet | NenPower

Jun 1, 2024 · 1. INNOVATIVE TECHNOLOGY The landscape of energy storage has witnessed a profound transformation, thanks in large part to the advent of new energy storage cabinets.

Get Started

New energy automobile chassis structure

The invention discloses a new energy automobile chassis structure which comprises a chassis body, wherein reinforcing rods are symmetrically arranged on the chassis body, battery

Get Started

Photovoltaic energy storage cabinet chassis sheet metal shell

Nov 21, 2024 · The photovoltaic energy storage market has an unprecedented demand for cabinets, chassis, and sheet metal shells, which are generally used for battery protection and

Get Started

Structural Analysis of Battery Pack Box for New

Oct 1, 2022 · The box structure of the power battery pack is an important issue to ensure the safe driving of new energy vehicles, which required relatively better

Get Started

China''s battery electric vehicles lead the world: achievements

Jun 1, 2022 · As energy shortage, climate change, and pollutant emissions have posed significant challenges to the sustainable development of the world automotive industry, the development

Get Started

Custom New Energy Battery Chassis Sheet Metal Parts Metal

Jul 25, 2025 · Custom New Energy Battery Chassis Sheet Metal Parts Metal Frame Fabrication, Find Details and Price about Spare Parts Metal Box Fabrication from Custom New Energy

Get Started

CN109103377A

New-energy automobile power battery cabinet and its forming method, the present invention relates to new energy resource power battery accessories field more particularly to new

Get Started

Unveiling New Energy Vehicle Chassis Technology

Jan 31, 2025 · The adoption of newenergy vehicles (NEVs) is reshaping the automotive landscape, with a strong emphasis on eco-friendly materials and reduced emissions. This

Get Started

Battle for the EV Battery Box

Mar 17, 2023 · The company''s process engineering manager Ben Lamm noted that the material, combined with Tri-Mack''s manufacturing process, offers new

Get Started

Cell-to-Chassis Architecture in EVs | Optimizing

Explore the benefits and challenges of cell-to-chassis architecture in electric vehicles, focusing on design optimization and material

Get Started

Complete Guide for Battery Enclosure

May 29, 2024 · Everyone wants a safe, durable, high quality and secure battery enclosure. However, finding the right information about these battery boxes or

Get Started

Energy Storage Chassis: The Game-Changer in Modern Power

Imagine an electric vehicle chassis that''s not just a skeleton but a power bank on wheels. That''s the energy storage chassis revolution in a nutshell. As of 2024, over 40% of new energy

Get Started

6 FAQs about [New energy battery cabinet chassis material]

What is an EV battery enclosure?

(Novelis) EV battery enclosures are a hotbed of subsystem design, materials innovation, and vehicle integration. Whether you call them packs, boxes, or trays, the structures that envelop and protect EV battery cells and their supporting electrical and thermal-management hardware are among the industry’s top subsystem priorities.

How much does an electric vehicle enclosure weigh?

Evolving vehicle architectures make composites an attractive material choice for the enclosures of future EVs. The average enclosure weighs 80-150 kg. Complexity in design & development -... Battery Electric Vehicles (BEV): 2030 = 28 Mil. / 2040 = 64 Mil. • Fuel Cell Electric Vehicles (FCEV): 2030 = 1.1 Mil. / 2040 = 7.7 Mil.

Are aluminum battery enclosures a good choice?

Aluminum battery enclosures typically deliver a weight savings of 40% compared to an equivalent steel design. According to Asfeth, the alloys best suited for battery enclosures are the 6000-series Al-Si-Mg-Cu family — alloys that are also highly compatible with end-of-life recycling, he said.

What makes Novelis a Gen-II battery enclosure?

Inside Novelis’ state-of-art Gen-II battery enclosure, from the top: Aluminum top cover; advanced cell-to-pack battery system (green); s701 and s650 roll-formed AL profiles; simple modular extruded frame enclosure; structurally integrated cooling plate (blue), fire resistant AL bottom plate. (Novelis)

What alloy is used in a Constellium dual-frame enclosure?

Aluminum’s workhorse 6xxx-series alloy is used in two different advanced extruded alloys that underpin a recent Constellium dual-frame enclosure prototype. The inner frame (a second buttress to protect the cells in an impact) is in strength-optimized 6000 (HSA6 family).

What is a 3-in-1 battery-box?

DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural components. Its housing is made of the company’s Zytel HTN, a nylon-based polyamide capable of resisting high temperatures.

Related Articles

-

New Energy Battery Cabinet Chassis

New Energy Battery Cabinet Chassis

-

New Energy Battery Cabinet Chassis Armor

New Energy Battery Cabinet Chassis Armor

-

New Energy Brand New Battery Cabinet

New Energy Brand New Battery Cabinet

-

New energy battery cabinet is unreliable

New energy battery cabinet is unreliable

-

Zero Degree New Energy Battery Cabinet

Zero Degree New Energy Battery Cabinet

-

German new energy battery cabinet manufacturing

German new energy battery cabinet manufacturing

-

Wellington New Energy Extended Range Battery Cabinet

Wellington New Energy Extended Range Battery Cabinet

-

New Energy Battery Cabinet Electronic Control

New Energy Battery Cabinet Electronic Control

-

New Energy Battery Cabinet Resistance

New Energy Battery Cabinet Resistance

-

Energy storage cabinet battery new energy track

Energy storage cabinet battery new energy track

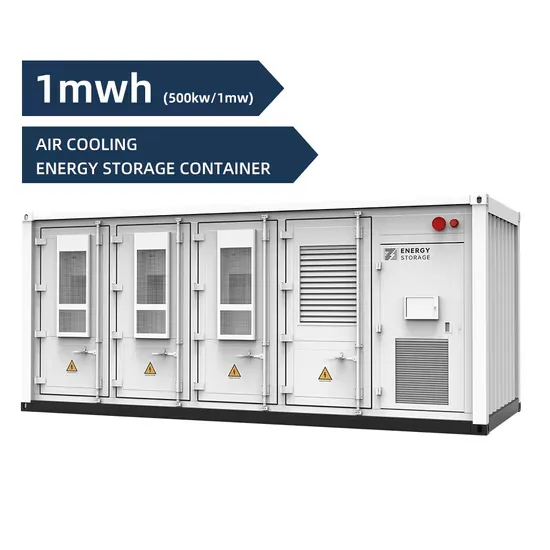

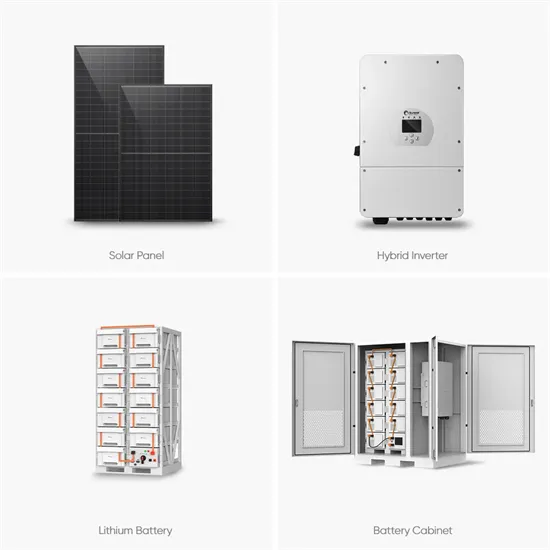

Commercial & Industrial Solar Storage Market Growth

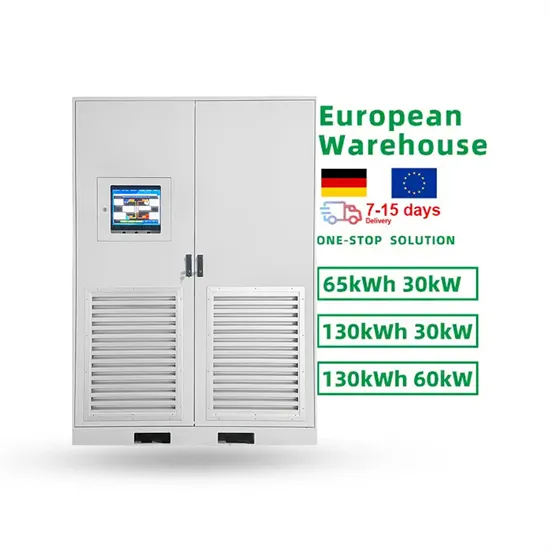

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.