Vanadium redox flow batteries: A technology

Oct 1, 2014 · Flow batteries have unique characteristics that make them especially attractive when compared with conventional batteries, such as their

Get Started

A review of vanadium electrolytes for vanadium redox flow batteries

Mar 1, 2017 · There is increasing interest in vanadium redox flow batteries (VRFBs) for large scale-energy storage systems. Vanadium electrolytes which function as

Get Started

Research progress in preparation of electrolyte for all-vanadium

Feb 25, 2023 · All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material

Get Started

Next-generation vanadium redox flow batteries:

Vanadium redox flow batteries (VRFBs) have emerged as a promising contenders in the eld of fi electrochemical energy storage primarily due to their excellent energy storage capacity,

Get Started

Advanced Electrolyte Formula for Robust

Jan 24, 2024 · Insufficient thermal stability of vanadium redox flow battery (VRFB) electrolytes at elevated temperatures (>40 °C) remains a challenge in the

Get Started

全钒液流电池在充电结束搁置阶段的开路电压变化

Nov 7, 2022 · Charge and shelf tests on an all-vanadium liquid flow battery are used to investigate the open-circuit voltage change during the shelving phase. It is discovered that the open-circuit

Get Started

Vanadium Battery | Energy Storage Sub-Segment – Flow Battery

Jun 30, 2025 · All-vanadium flow battery, full name is all-vanadium redox battery (VRB), also known as vanadium battery, is a type of flow battery, a liquid redox renewable battery with

Get Started

ALL-VANADIUM REDOX FLOW BATTERY

Nov 5, 2024 · Studies on the temperature stability of the electrolyte solution for the all-vanadium redox flow battery in the sulphuric acid system focus mainly on the high-temperature stability,

Get Started

A 3D modelling study on all vanadium redox flow battery at

Nov 1, 2023 · The operating temperature is found significantly influence the optimal design of VRFBs. Increasing the inlet flow rate and state of charge (SOC), decreasing the electrode

Get Started

Review—Preparation and modification of all-vanadium redox flow battery

Nov 21, 2024 · As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

Get Started

Influence of temperature on performance of all vanadium redox flow

Jun 14, 2018 · The main mass transfer processes of the ions in a vanadium redox flow battery and the temperature dependence of corresponding mass transfer properties of the ions were

Get Started

What you need to know about flow batteries

May 8, 2024 · Here all batteries (flow batteries included) have of course their issues, and the individual impact is related to the chosen chemistry. Due to the gained experience in the past

Get Started

Technical analysis of all-vanadium liquid flow batteries

Nov 27, 2024 · Electrolysis is currently the mainstream preparation method, using vanadium pentoxide as the raw material, produced in sulphuric acid, the operating temperature is

Get Started

All-vanadium redox flow batteries

Jan 1, 2025 · The most commercially developed chemistry for redox flow batteries is the all-vanadium system, which has the advantage of reduced effects of species crossover as it

Get Started

A Review of Capacity Decay Studies of All‐vanadium

Aug 13, 2024 · This review generally overview the problems related to the capacity attenuation of all-vanadium flow batteries, which is of great significance for understanding the mechanism

Get Started

A Wide‐Temperature‐Range Electrolyte for all Vanadium Flow Batteries

Jun 4, 2025 · A wide-temperature-range (WTR) vanadium electrolyte (−5 °C∼45 °C) has been proposed to address the poor thermal stability of all vanadium flow batteries. The WTR

Get Started

ALL-VANADIUM REDOX FLOW BATTERY

Nov 5, 2024 · NON-FLUORINATED PROTON EXCHANGE MEMBRANE Vanadium electrolyte at high temperature Heat is generated during the charging and discharging processes of all

Get Started

An Open Model of All-Vanadium Redox Flow Battery Based

Oct 19, 2021 · Based on the component composition and working principle of the all-vanadium redox flow battery (VRB), this paper looks for the specific influence mechanism of the

Get Started

Thermal modeling and temperature control of an all-vanadium redox flow

Jun 12, 2019 · Abstract: Previous studies have demonstrated that the electrolyte temperature of an all-vanadium redox flow battery (VRB) has a significant influence on the safety and

Get Started

Electrode materials for vanadium redox flow batteries:

Jan 1, 2022 · The design and future development of vanadium redox flow battery were prospected. Vanadium redox flow battery (VRFB) is considered to be one of the most

Get Started

A novel flow design to reduce pressure drop and enhance

Feb 1, 2025 · The Vanadium Redox Flow Battery (VRFB) is one of the promising stationary electrochemical storage systems in which flow field geometry is essential to ensure uniform

Get Started

A Wide-Temperature-Range Electrolyte for all Vanadium Flow Batteries

Jun 4, 2025 · The all-vanadium flow battery (VFB) has emerged as a highly promising large-scale, long-duration energy storage technology due to its inherent advantages, including decoupling

Get Started

Weifang Built The First 1MW/4MWh Hydrochloric Acid-based All-Vanadium

Jul 4, 2022 · The energy storage power station is the world''s most powerful hydrochloric acid-based all-vanadium redox flow battery energy storage power station. Compared with the

Get Started

Effects of operating temperature on the performance of vanadium

Oct 1, 2015 · Abstract For an operating flow battery system, how the battery''s performance varies with ambient temperatures is of practical interest. To gain an understanding of the general

Get Started

全钒液流电池提高电解液浓度的研究与应用现状

Nov 11, 2022 · The electrolyte of all Vanadium Redox Flow batteries (VRFB) is the solution of a single vanadium element with various valences, which avoids the cross-contamination caused

Get Started

Highly stable electrolyte enables wide temperature vanadium flow batteries

Jul 1, 2025 · Vanadium flow batteries (VFB) offer an ideal solution to the issue of storing massive amounts of electricity produced from intermittent renewables. Ho

Get Started

Towards a high efficiency and low-cost aqueous redox flow battery

May 1, 2024 · The factors affecting the performance of flow batteries are analyzed and discussed, along with the feasible means of improvement and the cost of different types of flow batteries,

Get Started

Vanadium batteries

Jan 1, 2021 · The control system for vanadium batteries is very important for their long-term stable operation, where the temperature, flow, flow distribution, charge and discharge voltages, and

Get Started

Advancing Flow Batteries: High Energy Density

Dec 17, 2024 · A high-capacity-density (635.1 mAh g − ¹) aqueous flow battery with ultrafast charging (<5 mins) is achieved through room-temperature liquid

Get Started

6 FAQs about [All-vanadium liquid flow battery adapts to temperature]

Are vanadium redox flow battery electrolytes stable at high temperatures?

Insufficient thermal stability of vanadium redox flow battery (VRFB) electrolytes at elevated temperatures (>40 °C) remains a challenge in the development and commercialization of this technology, which otherwise presents a broad range of technological advantages for the long-term storage of intermittent renewable energy.

Are vanadium flow batteries a viable solution to a high thermal precipitation problem?

Vanadium flow batteries (VFB) offer an ideal solution to the issue of storing massive amounts of electricity produced from intermittent renewables. However, the historical challenge of high thermal precipitation of V 2 O 5 from VO 2+ (∼50 °C for 1 day) represents a critical concern.

How stable is a vanadium electrolyte?

The stability of the vanadium electrolyte is also highly dependent on the temperature. Temperatures above 40 °C in the positive electrolyte and below 10 °C in the negative electrolyte commonly induce formation of solid V 2 O 5 and VSO 4 precipitates, respectively. [ 2]

What is a cooling system in a vanadium electrolyte?

Typically, cooling systems are employed to maintain the working temperature of the vanadium electrolyte in a safe range, preventing the V 2 O 5 precipitation.

Why does V2O5 precipitate a positive vanadium electrolyte?

The formation of V 2 O 5 precipitates not only reduces the energy density of the electrolyte, but also blocks the flow within the electrodes, damaging the VRFB and reducing its operational lifetime. Mechanism of precipitation in the positive vanadium electrolyte.

Does electrolyte temperature affect redox flow battery performance?

Conferences > 2019 12th Asian Control Confe... Previous studies have demonstrated that the electrolyte temperature of an all-vanadium redox flow battery (VRB) has a significant influence on the safety and efficiency of the battery. Therefore, an effective cooling strategy is required, especially for large-scale batteries.

Related Articles

-

All-vanadium liquid flow battery temperature

All-vanadium liquid flow battery temperature

-

All-vanadium liquid flow battery at low temperature

All-vanadium liquid flow battery at low temperature

-

The important components of all-vanadium liquid flow battery are

The important components of all-vanadium liquid flow battery are

-

New all-vanadium liquid flow battery pump in Equatorial Guinea

New all-vanadium liquid flow battery pump in Equatorial Guinea

-

All-vanadium liquid flow battery yellow

All-vanadium liquid flow battery yellow

-

Macedonian all-vanadium liquid flow battery

Macedonian all-vanadium liquid flow battery

-

How much vanadium does a 1mw all-vanadium liquid flow battery use

How much vanadium does a 1mw all-vanadium liquid flow battery use

-

All-vanadium liquid flow battery basic voltage

All-vanadium liquid flow battery basic voltage

-

Monaco Vanadium Liquid Flow Energy Storage Battery

Monaco Vanadium Liquid Flow Energy Storage Battery

-

Huawei iron-cadmium liquid flow battery

Huawei iron-cadmium liquid flow battery

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

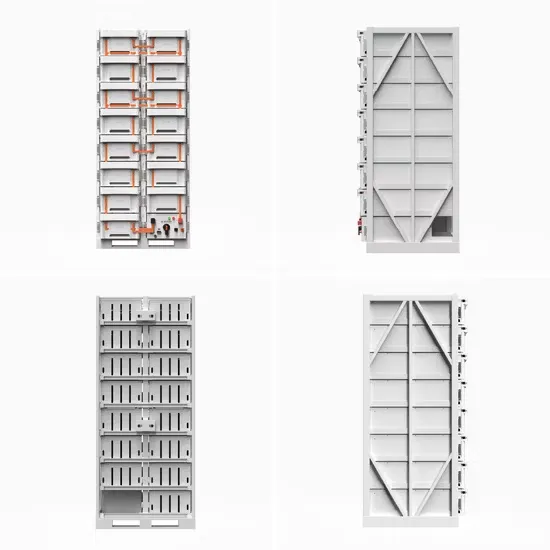

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.