Demystifying high-voltage power electronics for solar

Apr 1, 2023 · In all inverter configurations, the DC/DC stage uses high switching frequencies. However, the rail or DC link voltage could vary from as low as 200V to greater than 1kV

Get Started

What is a Three-Phase Inverter? | inverter

Sep 17, 2024 · Especially in high-power application scenarios, inverters need to withstand greater current and voltage stress, which imposes higher requirements on the selection of power

Get Started

How High Voltage Inverters Work

First, a high-voltage inverter converts the incoming AC voltage into DC voltage. Then, using a device called an inverter, it converts the DC voltage back to AC

Get Started

Power Inverter vs. Converter

Jan 26, 2020 · Differences Although both the power inverter and converter are used for voltage conversion, actually they make different power sources

Get Started

What Components In An Inverter Convert DC To

Jan 25, 2025 · Learn about the components in an inverter that convert DC to AC. Explore the role of power transistors, transformers, capacitors, and control

Get Started

Analysis of the Working Principle and Application of High Voltage Inverter

May 15, 2024 · The working principle of high voltage inverter is to control the speed of motor by changing the frequency of alternating current (AC), MICNO high voltage inverter adopts

Get Started

Inverter Pulse Width Modulation Control Techniques for

Oct 5, 2023 · The inverter essentially converts the input DC voltage into voltage pulses through pulse width modulation (PWM) such that the average voltage during a given switching period

Get Started

Your guide to power inverters | HDM Solar

A power inverter is an electrical device that converts the direct current (DC) electricity generated by your solar panels into alternating current (AC)

Get Started

Piezoelectric Transformer-Based High-Voltage Pulse

Jul 19, 2023 · The first stage generally consists of a high-step-up DC/DC converter that charges a DC-link capacitor to a high voltage (HV, typically several kV) from a low-voltage (LV) source.

Get Started

High Voltage Inverter: Unlocking the Potential of High

Aug 17, 2025 · Generally, a high voltage inverter is a type of inverter voltage that works by converting direct current (DC) into alternating current (AC) at high voltage. This high-voltage

Get Started

Power Conversion | Yaskawa Global Site

The AC Drive/inverter converts AC voltage to DC voltage through a rectifier circuit and performs reverse conversion to convert the DC voltage to any AC voltage

Get Started

Inverters and Rectifiers: How to Convert DC to

Jun 29, 2025 · 1What are inverters and rectifiers? Inverters and rectifiers are electronic circuits that can change the type of electric current. An inverter

Get Started

SPWM Inverter Block Diagram and Working

Sep 13, 2024 · Sinusoidal Pulse Width Modulation (SPWM) is a widely used technique for generating high-quality sinusoidal waveforms in inverter circuits.

Get Started

Bipolar PWM Single Phase Inverter with RL Load

Oct 27, 2024 · Introduction A bipolar PWM single-phase inverter is a type of power electronic device used to convert DC (direct current) power into AC (alternating current) power with a

Get Started

(PDF) Design and implementation of high

Dec 1, 2024 · The generator employs a push-pull inverter to transform the DC 12 V voltage into AC 400 V at a frequency of 20 kHz. A Cockcroft-Walton circuit,

Get Started

DC to AC Converters: Working Principles, Types,

Inverters are designed to support multiple input voltage levels, such as 12V, 24V, and 48V DC, depending on the power source and application. These voltage levels allow for flexibility in

Get Started

Full bridge single-phase inverter | high-voltage

Sep 6, 2024 · High Voltage Pulse Generator BoardFull bridge single-phase inverter A Full Bridge Single-Phase Inverter is a type of power inverter that

Get Started

Converting DC to AC: Basic Principles of Inverters

May 28, 2024 · This article investigates the basic principles of inverters, different types of DC-to-AC conversion, and common applications for generating AC

Get Started

PWM Current Source Inverters | part of High-Power

Oct 13, 2022 · This chapter focuses on the pulse‐width‐modulated (PWM) current source inverter (CSI) technologies for high‐power medium voltage drives. It analyses three modulation

Get Started

Practical Investigations on SCR Based HVDC Power

Jul 6, 2021 · Abstract. HVDC power transmission based converter uses both 6 pulse and 12 pulse schemes system. It is constructed mainly using the semiconductor devices for transfer of bulk

Get Started

GitHub

The project is an inverter that converts DC to AC . It involves designing a circuit that can efficiently step up the low voltage DC input to a high voltage AC output, using components like

Get Started

Full bridge single-phase inverter | high-voltage

Sep 6, 2024 · A Full Bridge Single-Phase Inverter is a type of power inverter that converts direct current (DC, Vd) into alternating current (AC, Vo). It uses four

Get Started

How Pulse Width Modulation in a VFD Works

Oct 10, 2021 · The process involved in inverting the DC voltage to the variable voltage variable frequency (VVVF) AC voltage in the inverter section of the

Get Started

What is a PWM Inverter: Types and Applications

Jul 15, 2024 · In this article, we will delve into PWM inverters, which are used in renewable energy systems and smart grid technologies. What is a PWM

Get Started

Types of Inverters

Jul 23, 2025 · What is Inverter? An inverter is a digital device that converts direct Current (DC) power into alternating contemporary (AC) energy. This

Get Started

Comparing Inverter Solutions: Silicon vs. Wide

Apr 24, 2025 · An inverter is an electronic circuit that converts direct current (DC) into alternating current (AC) power. By rapidly switching semiconductor

Get Started

Design of a High-Low Unipolar Pulse Width Modulated

Jun 12, 2025 · The purpose of this project is to convert a range of high DC voltage and convert it to an AC output voltage of 120 Vrms with a power rating of 100 W. Nonetheless, this particular

Get Started

CHAPTER 2

Dec 22, 2023 · 2.1 Introduction The dc-ac converter, also known as the inverter, converts dc power to ac power at desired output voltage and frequency. The dc power input to the inverter

Get Started

6 FAQs about [Inverter converts DC high voltage pulse]

How does a DC inverter work?

The inverter essentially converts the input DC voltage into voltage pulses through pulse width modulation (PWM) such that the average voltage during a given switching period equals the desired voltage command . The motor then generates current and torque which are applied to the mechanical system within which the electric motor drive is used.

How does a unipolar inverter work?

unipolar inverter using a full bridge topology. This inverter receives a D.C. voltage as an input and outputs an A.C. voltage. As the input voltage remains constant, the modulation of the switches. Pulse width modulation changes the width of the square wave to adjust the output voltage at high frequencies. As a result, the sinusoidal

Why do we need an inverter?

Therefore, an inverter is necessary to change the D.C. power to A.C. power. unipolar inverter using a full bridge topology. This inverter receives a D.C. voltage as an input and outputs an A.C. voltage. As the input voltage remains constant, the modulation of the switches. Pulse width modulation changes the width of the square

How does a power converter work?

The power converter, which is an inverter in this case, is driven by a gate driver. The gate driver generates voltage signals to drive the gates of the individual switches within the inverter resulting in the generation of phase to ground voltages that are applied to the terminals of the machine.

What is a power converter?

controlling the flow of electrical energy for various applications. To efficiently meet solid-state switches to achieve the desired voltage, current, or frequency. These converters vary from a low (mW) to a high (MW) power range. Nevertheless, energy consumption and production are very important issues concerning power electronics.

What is a DC link in a power converter?

Note that the DC link essentially refers to the voltage across the bulk capacitor which is located in close proximity to the power converter and acts as the primary power source for the drive system. These signals are then used along with estimated electrical position to compute the duty cycles for the individual phase legs of the power converter.

Related Articles

-

Low voltage to high voltage inverter for construction sites

Low voltage to high voltage inverter for construction sites

-

192v DC inverter input voltage range

192v DC inverter input voltage range

-

Manila High Voltage Inverter Sales

Manila High Voltage Inverter Sales

-

High voltage 100 000 volt inverter

High voltage 100 000 volt inverter

-

Does the high voltage electricity have an inverter

Does the high voltage electricity have an inverter

-

5kW high voltage inverter

5kW high voltage inverter

-

Bangi high voltage inverter

Bangi high voltage inverter

-

Photovoltaic 10kV high voltage inverter

Photovoltaic 10kV high voltage inverter

-

High voltage grid-connected inverter model

High voltage grid-connected inverter model

-

The impact of high voltage on inverter

The impact of high voltage on inverter

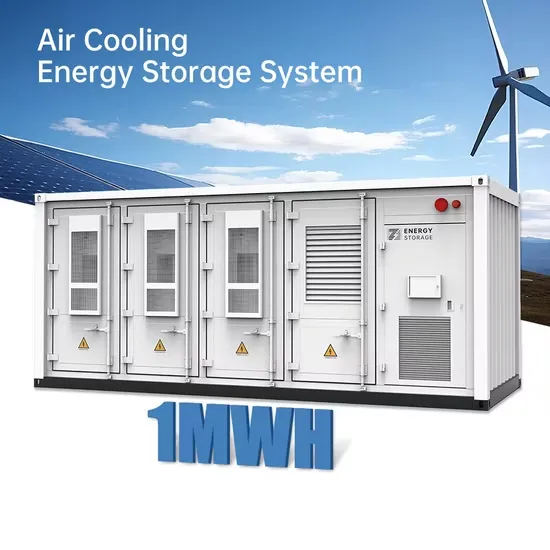

Commercial & Industrial Solar Storage Market Growth

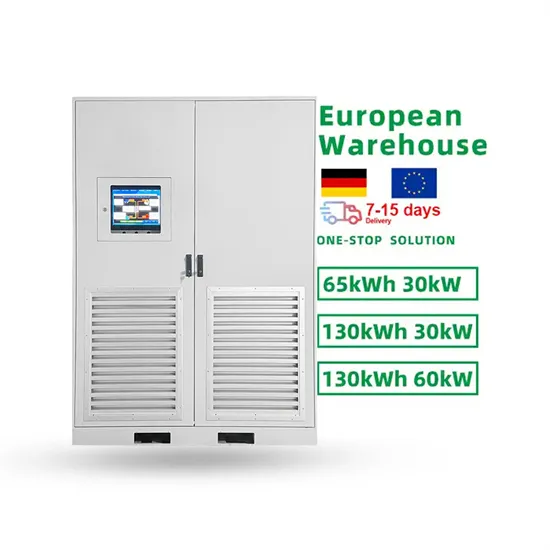

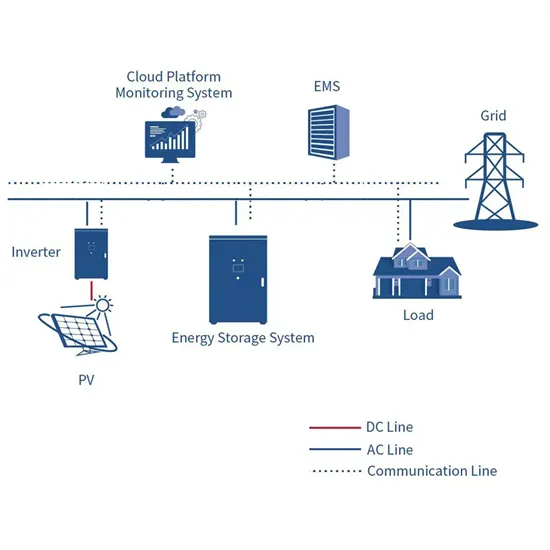

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

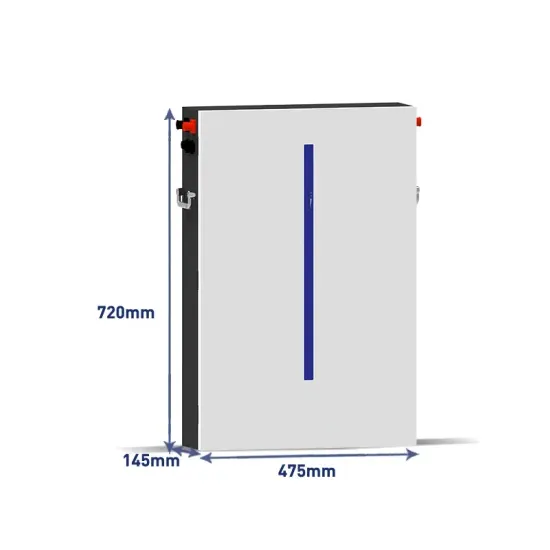

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.