Analysis and design of battery thermal management under

Apr 1, 2023 · Thermal management is critical for the safety of electric vehicle (EV) battery packs, especially under ultra-fast and extreme fast charging and discharging use conditions. Liquid

Get Started

A review of battery energy storage systems and advanced battery

May 1, 2024 · This review highlights the significance of battery management systems (BMSs) in EVs and renewable energy storage systems, with detailed insights into voltage and current

Get Started

Modeling and control strategy optimization of battery pack

Nov 1, 2024 · This paper establishes the liquid cooling thermal management system model for an electric vehicle''s battery pack, which accurately characterizes the temperature distribution and

Get Started

Battery Charging & Discharging: 10 Key

Mar 19, 2025 · Whether you are an engineer designing power systems, a solar energy enthusiast, or just someone looking to get the most out of your

Get Started

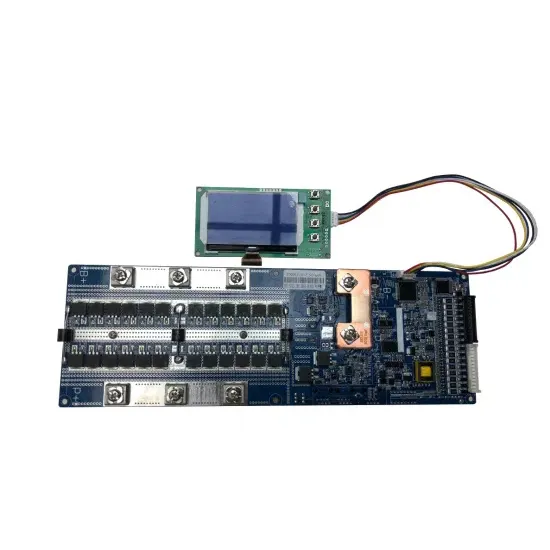

Application of Power MOSFET in Battery

Jun 30, 2022 · All of these factors pose strict technical design challenges for the charge and discharge management of power MOSFET in the large-capacity

Get Started

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get Started

Battery Pack Module Charging and Discharging

The EP401 is a battery pack module integrated charge-discharge machine designed based on the characteristics of lithium-ion batteries used in electrical

Get Started

Battery Module/Pack Test Systems | Enertest Solutions

The PTS Series battery pack cycler is designed for the systematic charging and discharging of battery packs. It is essential for testing the performance, capacity, and longevity of batteries

Get Started

A novel active lithium-ion cell balancing method based

May 6, 2025 · r flow of the Electric Vehicle (EV) with minimum balancing eforts and fully charge/discharge each cell in the battery pack. This ensures the better performance of the

Get Started

Battery Charge Discharge System for High

The battery charge discharge system is mainly applied to the high voltage battery pack, such as the battery packs of electric vehicles, electric bicycles, power

Get Started

EV Battery Efficiency''s Brain: Battery

Dec 9, 2024 · What is a Battery Management System (BMS)? The Battery Management System (BMS) is an intelligent electronic system that monitors,

Get Started

Battery Terminology: Charge and Discharge of a

Jan 22, 2025 · By following best practices for charging, discharging, and storage, users can prolong battery life, minimize degradation, and enjoy reliable power

Get Started

Battery Pack, Battery System | Ni-MH Batteries

Battery System FDK save our customers'' development resources by providing batteries with control functions according to the application. Our battery packs include a battery

Get Started

Can BMS Charging and Discharging

Sep 15, 2023 · Regardless of the circuit topology used, the Battery management system charging voltage outside the battery pack/BMS is either higher

Get Started

Charging control strategies for lithium‐ion

Nov 26, 2021 · The expanding use of lithium-ion batteries in electric vehicles and other industries has accelerated the need for new efficient charging strategies

Get Started

Analysis of the Charging and Discharging

Jul 5, 2021 · This article studies the process of charging and discharging a battery pack composed of cells with different initial charge levels.

Get Started

JETIR Research Journal

Jul 22, 2022 · The proposed two cases viz, during charging, discharging Charge (SOC) of the cells is initialized 3cells Li-ion battery pack. Battery Cell of SOC based cell balancing using a

Get Started

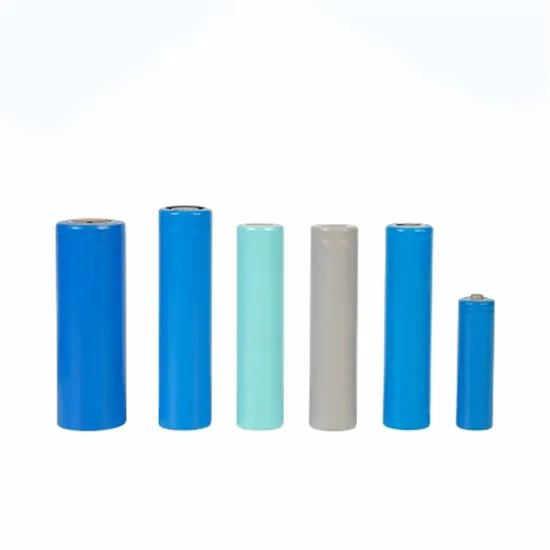

Introduction to Power Battery Packs-JONVER

Apr 10, 2025 · BMS (Battery Management System): Intelligently manages and monitors battery cells to prevent overcharging/over-discharging, extends battery life, and tracks battery status.

Get Started

A novel active lithium-ion cell balancing method based on charging

May 6, 2025 · In series and parallel strings connected Lithium-ion (Li-ion) battery modules or packs, it is essential to equalise each Li-ion cell to enhance the power delivery performance

Get Started

A Review on Battery Charging and Discharging

Apr 23, 2018 · Energy storage has become a fundamental component in renewable energy systems, especially those including batteries. However, in

Get Started

Fundamental Understanding of a Battery

Dec 7, 2023 · A Battery Management System (BMS) is an electronic system that manages and monitors the charging and discharging of rechargeable

Get Started

Battery Management System: Components,

Oct 7, 2024 · A battery management system (BMS) is a sophisticated control system that monitors and manages key parameters of a battery pack, such as

Get Started

The Application Of MOSFETs in Battery Management Systems

Nov 6, 2024 · The role of MOSFET in battery management system The Battery Management System (BMS) is an important component that ensures that the battery pack is always in

Get Started

Understanding battery management systems

May 31, 2025 · A battery-management system (BMS) is an electronic system or circuit that monitors the charging, discharging, temperature, and other factors

Get Started

Battery BMS: Understanding the Basics and its Importance

A Battery Management System (BMS) is an intelligent electronic system that monitors and controls the charging, discharging, and overall performance of a battery pack.

Get Started

Charging and Discharging of Electric Vehicles in

Feb 13, 2022 · This paper aims to provide a comprehensive and updated review of control structures of EVs in charging stations, objectives of EV management

Get Started

Optimization of charging strategy for lithium-ion battery packs

May 1, 2021 · First, a single-battery model based on electrothermal aging coupling is proposed; subsequently, a battery pack cooling model and battery pack equilibrium management model

Get Started

EV battery pack & management system essentials

Sep 3, 2024 · By controlling charging and discharging processes, the BMS prevents overcharging, overheating, and short circuits. It regulates battery temperature through cooling or heating

Get Started

Power Battery Pack Charging and Discharging Test System

Mar 24, 2025 · The global Power Battery Pack Charging and Discharging Test System market is experiencing robust growth, projected to reach a value of $871 million in 2025, exhibiting a

Get Started

Battery Charging

Apr 1, 2023 · NI-CD/NI-MH CHARGING INFORMATION In the realm of battery charging, charging methods are usually separated into two gen-eral categories: Fast charge is typically a system

Get Started

Charging of Battery and Discharging of Battery

Feb 24, 2012 · Contents 💡 Key learnings: Charging and Discharging Definition: Charging is the process of restoring a battery''s energy by reversing the

Get Started

BU-501: Basics about Discharging

Oct 27, 2021 · The cutoff voltage should also be lowered when discharging at very cold temperatures, as the battery voltage drops and the internal battery

Get Started

Application of Power MOSFET in Battery Management

Jul 15, 2022 · Power MOSFETs are connected in series between the inside of the lithium-ion battery pack and the output load Power MOSFETs are required to be connected in series

Get Started

How to Discharge a Battery?

Feb 21, 2025 · Discharging a battery is a key aspect of battery maintenance, but it''s not always straightforward. Whether you''re managing rechargeable devices or ensuring optimal

Get Started

Charging control strategies for lithium‐ion

Nov 26, 2021 · Numerous attempts have been conducted to establish optimal charging techniques for commercial lithium-ion batteries during the last

Get Started

Battery Charging and Discharging Optimization

Jul 31, 2025 · Battery thermal management system and charging/discharging control method for electric vehicles that improves battery life and safety by

Get Started

6 FAQs about [Battery pack charging and discharging system]

What is the difference between charging and discharging a battery?

Charging and Discharging Definition: Charging is the process of restoring a battery’s energy by reversing the discharge reactions, while discharging is the release of stored energy through chemical reactions. Oxidation Reaction: Oxidation happens at the anode, where the material loses electrons.

How does a lithium-ion battery pack work?

However, a battery pack with such a design typically encounter charge imbalance among its cells, which restricts the charging and discharging process . Positively, a lithium-ion pack can be outfitted with a battery management system (BMS) that supervises the batteries' smooth work and optimizes their operation .

How do EVs charge & discharge?

The key to EVs is their power batteries, which undergo a complex yet crucial charging and discharging process. Understanding these processes is crucial to grasping how EVs efficiently store and use electrical energy. This article will explore the intricate workings of the charging and discharging processes that drive the electric revolution.

How does a battery charger work?

A battery charger has three primary functions: initiate charging, rate optimization, and charge termination. Simply speaking, the charging process measures the voltage across the battery, then initiates the charging process until a specific voltage is reached, after which the charging process is terminated .

What happens during the charging and discharging process?

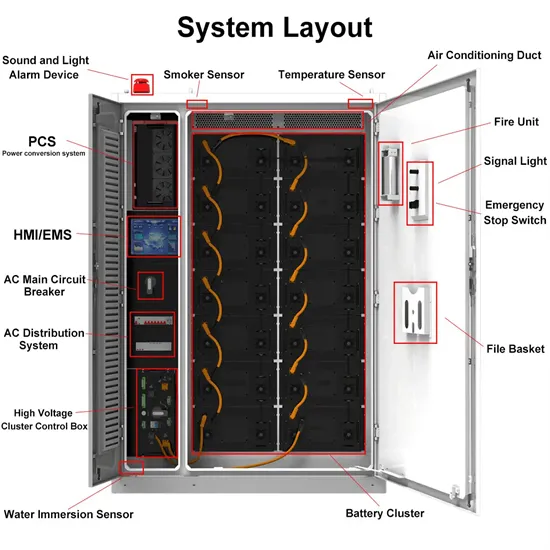

During the charging and discharging process, the voltage of each single cell, terminal voltage, terminal current, the charging and discharging status, the charging and discharging capacity, etc. are monitored in real time. Automatically saves historical charging and discharging records, supporting both curve and bar chart data display formats.

Can a controller optimize a battery discharge profile?

The designed controller balances the competing factors, such as battery lifetime, and charging time. Accordingly, only the optimal charging is considered since discharging is user-dependent. The authors claim that their proposed framework may also be applied to optimize the discharge profile.

Related Articles

-

Lithium battery pack charging and discharging prices

Lithium battery pack charging and discharging prices

-

Battery pack charging and discharging system

Battery pack charging and discharging system

-

New energy charging and discharging battery cabinet equipment

New energy charging and discharging battery cabinet equipment

-

Senegal lithium battery pack charging method

Senegal lithium battery pack charging method

-

Lithium iron phosphate battery pack forced charging

Lithium iron phosphate battery pack forced charging

-

Charging and discharging of lithium battery energy storage cabinet

Charging and discharging of lithium battery energy storage cabinet

-

Lithium battery pack charging overvoltage charging

Lithium battery pack charging overvoltage charging

-

Battery energy storage power station charging and discharging efficiency

Battery energy storage power station charging and discharging efficiency

-

Swiss RV modified lithium battery pack

Swiss RV modified lithium battery pack

-

How much does a lithium battery pack cost in Kenya

How much does a lithium battery pack cost in Kenya

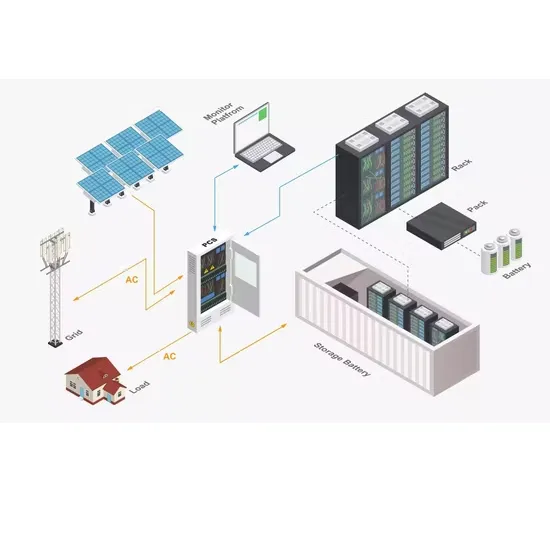

Commercial & Industrial Solar Storage Market Growth

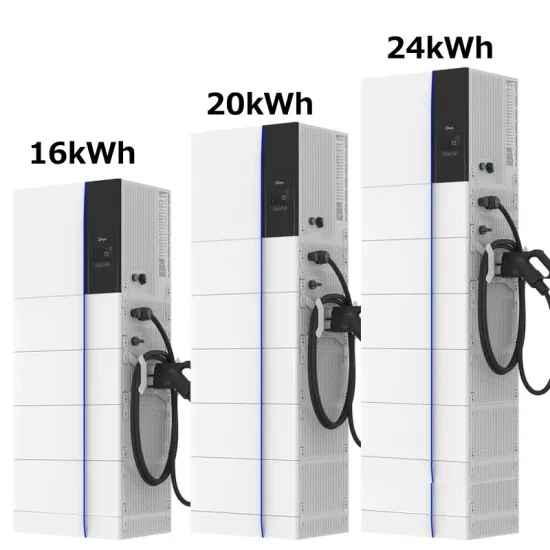

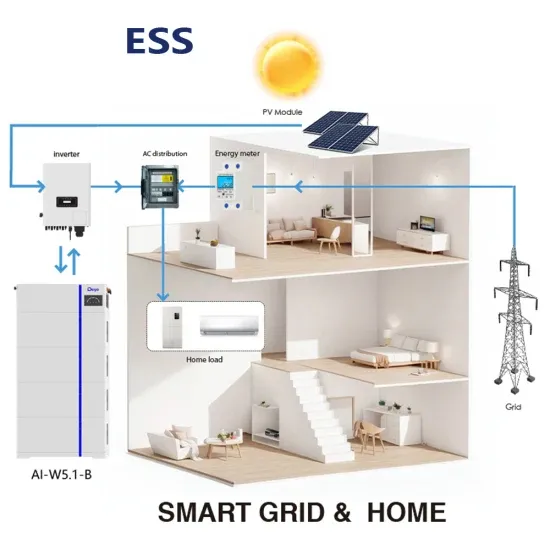

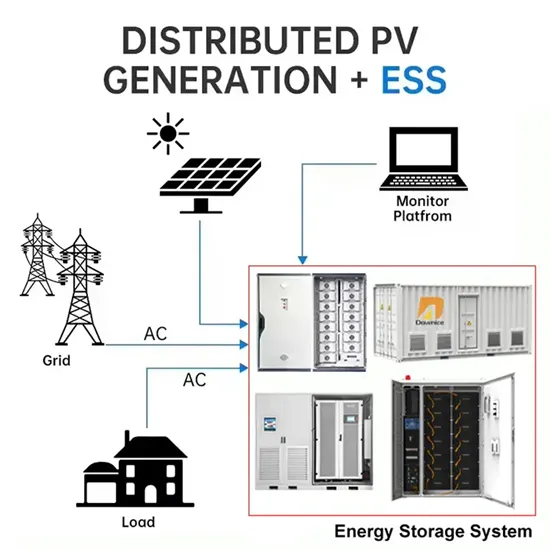

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.