How This Mechanical Battery is Making a

Dec 3, 2024 · This is the Dinglun Flywheel Energy Storage Power Station. At 30 MW, this is likely the biggest Flywheel Energy Storage System on the planet.

Get Started

The development of a techno-economic model for the

Oct 1, 2021 · The composite rotor flywheel energy storage system costs more than the steel rotor flywheel energy storage system because composite materials are still in the research and

Get Started

Technology: Flywheel Energy Storage

Oct 30, 2024 · Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to

Get Started

Amber Kinetics M32

Sep 26, 2020 · The Amber Kinetics M32 (8kW,32kWh) is the first commercialized four-hour discharge duration Kinetic Energy Storage System (KESS) powered by advanced flywheel

Get Started

What is Flywheel Energy Storage? | Linquip

Apr 4, 2023 · Electric energy is supplied into flywheel energy storage systems (FESS) and stored as kinetic energy. Kinetic energy is defined as the "energy

Get Started

A review of flywheel energy storage rotor materials and

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Get Started

What is the price of flywheel energy storage?

May 24, 2024 · 1. The cost of flywheel energy storage systems varies significantly based on numerous factors, such as technology type and scale of

Get Started

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Get Started

The most complete analysis of flywheel energy

Aug 23, 2023 · This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other

Get Started

Energy Storage Flywheel Rotors—Mechanical

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in

Get Started

Development and prospect of flywheel energy storage

Oct 1, 2023 · With the rise of new energy power generation, various energy storage methods have emerged, such as lithium battery energy storage, flywheel energy sto

Get Started

The development of a techno-economic model for the

Oct 1, 2021 · The ranges obtained in the uncertainty analysis for the levelized cost of storage are $122.08-$253.52/MWh and $108.63-$187.64/MWh for the composite rotor and steel rotor

Get Started

The development of a techno-economic model for the

Oct 1, 2021 · Two rotor configurations were considered: composite rotor flywheel and steel rotor flywheel. The total investment costs of the composite rotor and steel rotor flywheel storage

Get Started

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Get Started

RotorVault Energy Storage Cost Analysis and Flywheel Price

5 days ago · RotorVault has a similar up-front cost, and significantly lower total cost of ownership. Compared to other technologies like supercapacitors and legacy flywheels, RotorVault has

Get Started

Flywheel Energy Storage System Basics

Sep 23, 2021 · Today, flywheel energy storage systems are used for ride-through energy for a variety of demanding applications surpassing chemical batteries.

Get Started

Flywheel Energy Storage Systems | Electricity

1 day ago · RotorVault flywheel storage systems provide reliable energy storage solutions for residential, commercial and grid-scale applications worldwide.

Get Started

Concrete flywheel storage system for residential

Jun 21, 2021 · A French start-up has developed a concrete flywheel to store solar energy in an innovative way. Currently being tested in France, the storage

Get Started

How much does a flywheel energy storage system cost?

Cost summary for 20 MW/5MWh flywheel energy storage systems. How much does rotor flywheel storage cost? A bottom-up cost model was developed to assess the levelized cost of flywheel

Get Started

Analysis of Standby Losses and Charging Cycles

Aug 27, 2020 · Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system

Get Started

Flywheels | Climate Technology Centre & Network | Tue,

Aug 12, 2025 · The mechanics of energy storage in a flywheel system are common to both steel- and composite-rotor flywheels. In both systems, the momentum (the product of mass times

Get Started

How much does a flywheel energy storage system cost?

The Amber Kinetics flywheel is the first commercialized four-hour discharge, long-duration Flywheel Energy Storage System (FESS) solution powered by advanced technology that

Get Started

How much does a flywheel energy storage

Mar 2, 2024 · How much does a flywheel energy storage system cost? 1. The cost of a flywheel energy storage system varies based on several factors,

Get Started

Flywheel Battery Price: Cost Analysis and Market Trends for Energy

Apr 12, 2025 · Flywheel systems store energy by spinning a rotor at high speeds—up to 50,000 RPM. Unlike chemical batteries, they require no toxic materials and last over 20 years. But

Get Started

The Amber Kinetics Energy Storage System

Amber Kinetics pioneered long duration flywheel energy storage and is now revolutionizing the field by providing high speed, rapid response and near

Get Started

Composite Flywheels for Energy Storage

Jun 7, 2017 · Composite flywheels are designed, constructed, and used for energy storage applications, particularly those in which energy density is an important factor. Typical energies

Get Started

Flywheel Energy Storage Costs Decoded: A 2024 Price

Feb 1, 2022 · Our analysis reveals why California''s latest 20MW flywheel installation spent 38% less than traditional battery farms. Who Needs This Price Breakdown? The $64,000 Question:

Get Started

Flywheel Systems for Utility Scale Energy Storage

Apr 6, 2022 · Flywheel Systems for Utility Scale Energy Storage is the final report for the Flywheel Energy Storage System project (contract number EPC-15-016) conducted by Amber Kinetics, Inc.

Get Started

Rotor Design for High-Speed Flywheel Energy Storage

Sep 25, 2018 · Contemporary flywheel energy storage systems, or FES systems, are frequently found in high-technology applications. Such systems rely on advanced high-strength materials

Get Started

6 FAQs about [Flywheel energy storage rotor price]

How much does rotor flywheel storage cost?

A bottom-up cost model was developed to assess the levelized cost of flywheel storage. Composite and steel rotor flywheels were assessed for frequency regulation. The steel rotor flywheel has a lower capital cost and levelized cost of storage. The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively.

How much does rotor storage cost?

Two rotor configurations were considered: composite rotor flywheel and steel rotor flywheel. The total investment costs of the composite rotor and steel rotor flywheel storage systems are $25.88 million and $18.28 million, respectively. The corresponding levelized costs of storage are $189.94/MWh and $146.41/MWh.

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

What is rotorvault flywheel storage?

RotorVault flywheel storage systems provide reliable energy storage solutions for residential, commercial and grid-scale applications worldwide.

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

How much does a flywheel power converter cost?

The costs of a power converter for composite and steel flywheels are $49,618 and $52,595, respectively. The cost difference is due to the difference in rated power, 100 kW for the composite flywheel and 108 kW for the steel flywheel. Fig. 5. Equipment cost distribution for the flywheel energy storage systems.

Related Articles

-

The price of wind power flywheel energy storage

The price of wind power flywheel energy storage

-

Price application of flywheel energy storage

Price application of flywheel energy storage

-

Flywheel energy storage battery discharge price

Flywheel energy storage battery discharge price

-

Flywheel energy storage regenerative braking price

Flywheel energy storage regenerative braking price

-

Energy storage inverter structure price

Energy storage inverter structure price

-

Price comparison of mobile energy storage vehicles in El Salvador

Price comparison of mobile energy storage vehicles in El Salvador

-

Cambodia smart energy storage battery price

Cambodia smart energy storage battery price

-

New Energy Charging Station Flywheel Energy Storage Station

New Energy Charging Station Flywheel Energy Storage Station

-

Cape Town energy storage lead acid battery price

Cape Town energy storage lead acid battery price

-

Sodium battery energy storage unit price

Sodium battery energy storage unit price

Commercial & Industrial Solar Storage Market Growth

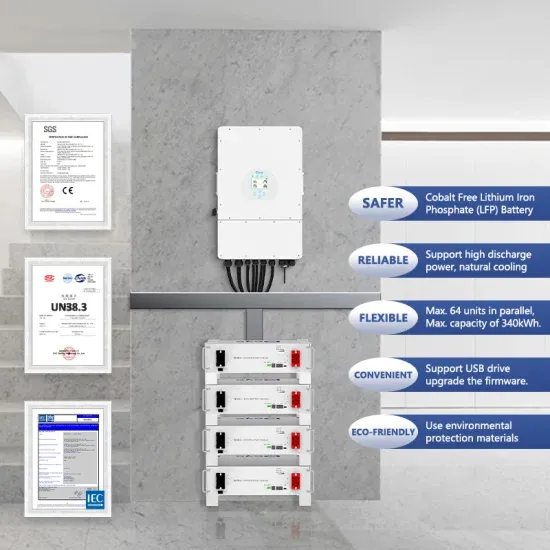

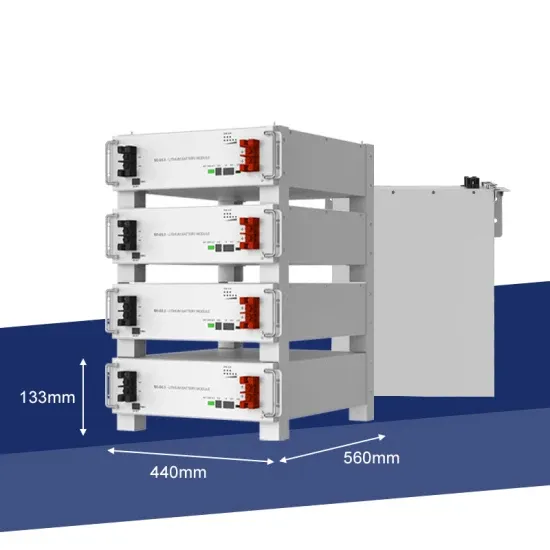

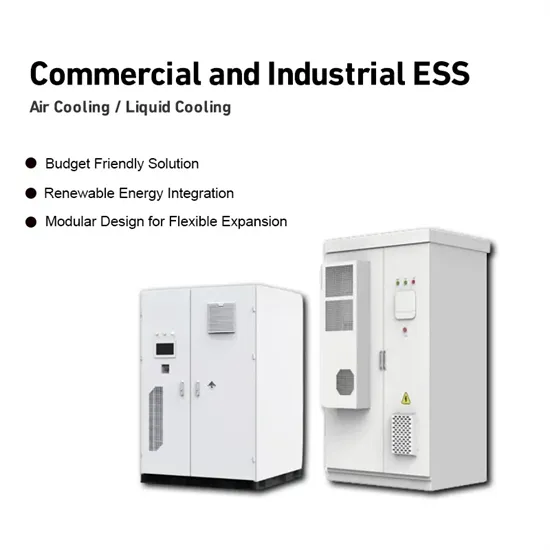

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.