How to design cost-sensitive battery-monitoring

Jul 15, 2016 · The circuit was designed to keep the output voltage below 1.2V for a 1A load current and 5.5V battery voltage. Equations 4, 5 and 6 show

Get Started

How integrated resistor dividers improve EV battery

Oct 2, 2024 · In this article, I''ll show how integrated high-voltage resistor dividers can offer a more precise and space-efficient approach to voltage attenuation compared to discrete resistor

Get Started

How Voltage Dividers Work

3 days ago · Learn about voltage dividers and their practical applications. Also see how to calculate voltage drop, resistance, current, and output voltage in a

Get Started

Voltage Divider Circuit

Jun 28, 2023 · The voltage divider circuit is an important building block in electronics . This article discusses the theory and application of different kinds

Get Started

Voltage divider

Aug 13, 2012 · An example of a voltage divider consists of two resistors in series or a potentiometer. It is commonly used to create a reference voltage, or to get a low voltage signal

Get Started

How to design cost-sensitive battery-monitoring

Jul 15, 2016 · In portable electronics designs, typical battery-monitoring systems measure battery voltage and battery current to detect when the battery needs

Get Started

Battery divider cabinet fluxgate current sensor DXE-CAB500

China Battery Divider Cabinet Fluxgate Current Sensor products offered by Shanghai Zhilong Electronic Technology Co.,ltd, and find Battery Divider Cabinet Fluxgate Current Sensor on

Get Started

5 Voltage divider circuits that go beyond dividing

Aug 23, 2017 · Turns out, voltage dividers aren''t just for dividing. Here are five Voltage Divider Circuits that give this simple circuit a lot of functionality.

Get Started

Voltage Divider Calculator: Explanation, Formula, and Circuit

Apr 11, 2025 · A voltage divider is a circuit that divides input voltage into smaller, adjustable outputs using resistors. Its formula, Vout = Vin × (R2 / (R1 + R2)), calculates the output based

Get Started

Simple battery monitoring! IC with a "supply

Jul 30, 2025 · A divider resistor is used to divide the power voltage to prevent the monitored battery voltage from exceeding the withstand voltage of the

Get Started

Voltage Divider: What is it? (Circuit And

Feb 24, 2012 · A voltage divider is a fundamental circuit in the field of electronics which can produce a portion of its input voltage as an output. It is formed

Get Started

Mdsc-S11-128/10A Lithium Battery Capacity

Dec 30, 2014 · Mdsc-S11-128/10A Lithium Battery Capacity Divider/Battery Power Capacity Dividing Equipment/Cell Grading Cabinet, Find Details and Price

Get Started

Voltage Dividers Explained: What are They and

Mar 8, 2024 · In this blog, we will delve into the world of voltage dividers, explaining their function, applications, and real-world examples.

Get Started

Voltage Divider Rule and Voltage Division

Basic Electronics Tutorials about the Voltage Divider Circuit which uses the voltage division rule to produce different voltage levels form a single voltage

Get Started

Understanding Voltage Divider Circuits

Aug 28, 2023 · Understanding Voltage Divider Circuits Voltage divider circuits are fundamental to many electrical engineering applications. With their simple setup and robust utility, they offer

Get Started

battery divider cabinet for battery pack assembly line

May 26, 2025 · It uses dedicated program-controlled equipment to charge and discharge the battery, and records test point data to analyze battery quality. This link is crucial in battery

Get Started

Voltage Dividers: Operations and Functions

Nov 7, 2022 · Learn the function and operation of voltage dividers as well as some considerations when incorporating them into your design

Get Started

What is a voltage divider

Nov 11, 2024 · How Does a Voltage Divider Work? A voltage divider works by distributing the input voltage among two or more components connected in series. The output voltage is taken

Get Started

What is a Voltage Divider? A Comprehensive Guide

Aug 17, 2025 · A voltage divider is a simple yet powerful circuit that generates a specific voltage output from a higher input voltage. It is achieved using two

Get Started

How does a battery capacity divider detect battery capacity?

Charging: Place the battery in the capacity divider, set the charging current and voltage parameters, and charge the battery until it reaches the rated voltage. For example, for

Get Started

proper voltage divider for battery voltage detection

Jul 20, 2016 · It allows you to use a large voltage divider to prevent battery drain. 1M is perfectly fine. I am using 2 x 1M to measure a 6..8V battery. Response time is usually not an issue with

Get Started

Battery Management System Voltage Division

Battery management system (BMS) is technology dedicated to the oversight of a battery pack, which is an assembly of battery cells, electrically organized in a row x column matrix

Get Started

Battery Management System Voltage Division

Thermal Management: Ensures batteries operate within safe temperature ranges to prevent overheating or thermal runaway.; Overvoltage and Undervoltage Protection: Prevents the

Get Started

Getting Started with Voltage Dividers | A

Nov 27, 2024 · In this guide we will be taking a practical look at Voltage dividers - one of the most fundamental circuits in the world of electronics and this guide

Get Started

How to choose a battery divider cabinet? Select the

Select the corresponding divider cabinet based on the type and capacity of the battery - EST group is a national high-tech enterprise that provides full industry supply chain services for the

Get Started

Voltage Divider

Feb 9, 2018 · The two resistor voltage divider is used often to supply a voltage different from that of an available battery or power supply. In application the output voltage depends upon the

Get Started

DESIGN FOR SAFE AND RELIABLE ELECTRICAL

Jan 23, 2019 · Battery manufacturers provide a value of short circuit current which needs to be used for validation of proper protection device. Duration of this short circuit current can be of

Get Started

Lithium-Ion Battery Charging Cabinet: Safe, Compliant, and

Aug 15, 2025 · Discover the importance of a lithium-ion battery charging cabinet for safe storage, charging, and fire protection in workplaces. Learn about US and EU regulations, safety

Get Started

Maximize EV Battery Longevity with Integrated Resistor Dividers

Mar 3, 2025 · Monolithic ratiometric resistor dividers provide a low-drift solution for converting the high voltages in modern EV battery packs into voltages suitable for conversion and processing

Get Started

Voltage Dividers

Introduction A voltage divider is a simple circuit which turns a large voltage into a smaller one. Using just two series resistors and an input voltage, we can create an output voltage that is a

Get Started

Voltage Dividers: How This Simple Circuit Brings

The voltage divider is one of the primary circuits in electronics. This simple yet powerful circuit is used in electronic and electrical engineering due to its ability

Get Started

6 FAQs about [Battery cabinet voltage divider insurance function]

How does a divider resistor work?

A divider resistor is used to divide the power voltage to prevent the monitored battery voltage from exceeding the withstand voltage of the microcontroller that is used. To conserve battery power, the current flowing through the divider resistor is controlled by a transistor. (The red portion in the figure below)

Is a voltage divider free?

It is not free. The amount of energy removed from the battery by the cap is more than the 160 nA that the analog input draws so the cap accomplishes nothing. If you use two 470 k resistors for the voltage divider, the total resistance across the battery is 940 k.

How much energy is removed from a battery by a voltage divider?

The amount of energy removed from the battery by the cap is more than the 160 nA that the analog input draws so the cap accomplishes nothing. If you use two 470 k resistors for the voltage divider, the total resistance across the battery is 940 k. If you had a 3.7v battery, the drain would 3.9 uA.

How do battery-voltage and current-monitoring systems work?

In portable electronics designs, typical battery-monitoring systems measure battery voltage and battery current to detect when the battery needs charging or replacement. In this post, I’ll demonstrate battery-voltage and current-monitoring circuitry for cost-optimized systems using operational amplifiers (op amps).

What is a voltage divider?

Voltage dividers can be used to adjust the level of a signal, especially digital ones. For example, level shifting from a common 5V HIGH digital signal to a 3.3V digital signal. With a voltage divider, a crude level shifter can be created to allow logic circuits that operate at 5V to interface with those that operate at 3.3V.

What is a capacitor voltage divider?

Capacitive voltage dividers have multiple applications - from touch-sensitive screens to Colpitts oscillators. Coming out from the voltage source, placing a resistor and then a capacitor in series creates a first-order lowpass RC filter (contrasted with a capacitor and resistor, creating a high-pass filter).

Related Articles

-

The function of the battery cabinet maintenance column

The function of the battery cabinet maintenance column

-

Installation of voltage stabilized power supply battery cabinet

Installation of voltage stabilized power supply battery cabinet

-

Energy storage battery cabinet communication high voltage

Energy storage battery cabinet communication high voltage

-

Battery cabinet electrical system function

Battery cabinet electrical system function

-

What is the voltage of the new power battery cabinet

What is the voltage of the new power battery cabinet

-

New energy plus battery cabinet plus insurance

New energy plus battery cabinet plus insurance

-

What is the function of the power station battery cabinet

What is the function of the power station battery cabinet

-

Battery cabinet life of communication high voltage cabinet

Battery cabinet life of communication high voltage cabinet

-

Communication high voltage battery energy storage cabinet working price

Communication high voltage battery energy storage cabinet working price

-

Battery cabinet electric heating system function

Battery cabinet electric heating system function

Commercial & Industrial Solar Storage Market Growth

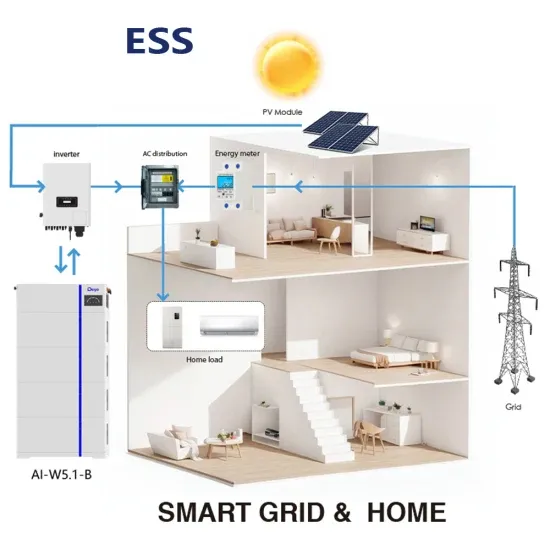

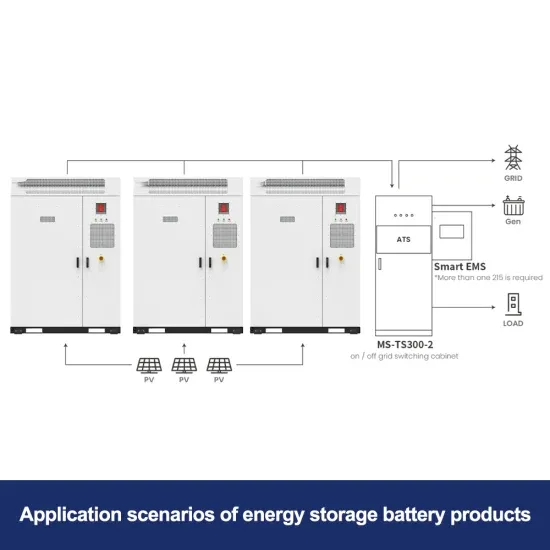

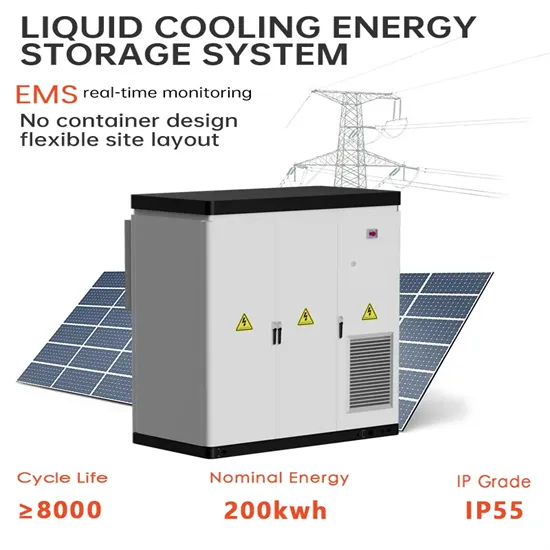

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

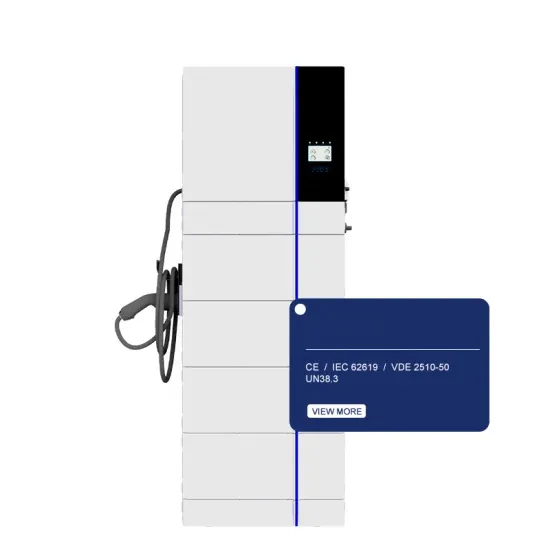

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.