Artificial intelligence computational techniques of flywheel energy

Dec 1, 2024 · However, the intermittent nature of these RESs necessitates the use of energy storage devices (ESDs) as a backup for electricity generation such as batteries,

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Get Started

Applications of flywheel energy storage system on load

Mar 1, 2024 · The power regulation topology based on flywheel array includes a bidirectional AC/DC rectifier inverter, LC filter, flywheel energy storage array, permanent magnet

Get Started

The High-speed Flywheel Energy Storage System

Sep 25, 2018 · A flywheel energy storage system converts electrical energy supplied from DC or three-phase AC power source into kinetic energy of a spinning mass or converts kinetic

Get Started

Enhancing vehicular performance with flywheel energy storage

Dec 10, 2024 · Flywheel Energy Storage Systems (FESS) are a pivotal innovation in vehicular technology, offering significant advancements in enhancing performance in vehicular

Get Started

Flywheel Energy Storage System based on boost DC-AC

An additional DC-DC boost converter is used in conventional configuration of Flywheel Energy Storage System (FESS) to regulate the output voltage during flywheel low speeds. This paper

Get Started

Overview of Control System Topology of

Nov 25, 2024 · Abstract. Flywheel energy storage system (FESS) technologies play an important role in power quality improvement. The demand for FESS

Get Started

A Novel Flywheel Array Energy Storage System with DC

Oct 21, 2020 · Flywheel Energy Storage System (FESS) becomes more attractive than other energy storage technologies due to its significant advantages. Single flywheel has limi

Get Started

Flywheel Energy Storage

Jan 12, 2024 · ABSTRACT Direct current (DC) system flywheel energy storage technology can be used as a substitute for batteries for providing backup power to an uninterruptible power

Get Started

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract—While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Get Started

Low voltage ride through of a flywheel energy storage

Mar 27, 2025 · For stabilizing the power grid during voltage dips, a doubly fed induction machines (DFIM)-based flywheel energy storage system is applied in this paper. The reactive power

Get Started

A Review of Flywheel Energy Storage System

The power electronic converter topologies that can be used for FESS applications are DC-AC, AC-AC, and AC-DC-AC, or a combination of these. The switching

Get Started

Flywheel vs. Supercapacitor as Wayside Energy

Jun 13, 2019 · Energy storage technologies are developing rapidly, and their application in different industrial sectors is increasing considerably. Electric rail

Get Started

(PDF) Implementation and Control of an AC/DC/AC

May 22, 2012 · An all-electric driveline based on a double wound flywheel, connected in series between main energy storage and a wheel motor, is presented. The flywheel works as a

Get Started

Technology: Flywheel Energy Storage

Oct 30, 2024 · Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Flywheels store rotational kinetic energy in the form of a spinning cylinder or disc, then use this stored kinetic energy to regenerate electricity at a later time. The amount of

Get Started

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · Electrical power is normally transmitted from a nominally constant voltage direct current (DC) link to and from the motor-generator (MG) via a power converter. This converter

Get Started

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

Get Started

A review of flywheel energy storage systems: state of the art

Feb 1, 2022 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Get Started

Mitigation effect of flywheel energy storage on the

Dec 1, 2023 · Shen et al. (2020) proposed a hybrid energy storage technology including flywheel energy storage and battery energy storage for the DC microgrid system of photovoltaic power

Get Started

The Status and Future of Flywheel Energy Storage

Jun 26, 2019 · Electrical power is normally transmitted from a nominally constant voltage direct current (DC) link to and from the motor-generator (MG) via a power con-verter. This converter

Get Started

Flywheel energy storage systems: A critical

Jul 19, 2021 · Various converters such as AC-AC, DC-AC, AC-DC-AC, or a combination can be employed in FESS-based applications. Based on

Get Started

Flywheel Energy Storage System for Electric Start and an

Jan 23, 2024 · Flywheel technology overcomes some of the shortcomings of today''s energy storage systems by having an extremely high cyclic-life, limited temperature sensitivity, no

Get Started

Conventional Free Energy using Flywheel

May 2, 2016 · Fig. 1: Flywheel Stores Energy [2] Advances in magnetic bearings, power electronics, and flywheel materials coupled with integration of mechanisms have resulted in

Get Started

A Review of Flywheel Energy Storage System

Energy storage systems (ESS) provide a means for improving the efficiency of electrical systems when there are imbalances between supply and demand.

Get Started

A new grid-stabilizing component: a flywheel energy storage

Mar 3, 2023 · The increasing share of renewable energy sources causes a reduction of inertia provided by conventional synchronous generators to the grid. To enable a stable operation in

Get Started

Flywheel Energy Storage System based on boost DC-AC

Sep 8, 2011 · An additional DC-DC boost converter is used in conventional configuration of Flywheel Energy Storage System (FESS) to regulate the output voltage during flywheel low

Get Started

Comparative analysis of AC and DC bus configurations for flywheel

Aug 1, 2020 · Since different power electronic devices are implemented in the AC and DC bus architectures, the Total Harmonic Distortion is assessed to quantify their impact on current and

Get Started

6 FAQs about [Flywheel energy storage AC or DC]

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

How does a flywheel energy storage system work?

Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000 rpm. Electrical energy is thus converted to kinetic energy for storage. For discharging, the motor acts as a generator, braking the rotor to produce electricity.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

What is a flywheel & how does it work?

Flywheels with the main attributes of high energy efficiency, and high power and energy density, compete with other storage technologies in electrical energy storage applications, as well as in transportation, military services, and space satellites .

What is a flywheel energy storage system (fess)?

According to Al-Diab (2011) the flywheel energy storage system (FESS) could be exploited beneficially in dealing with many technical issues that appear regularly in distribution grids such as voltage support, grid frequency support, power quality improvement and unbalanced load compensation.

Related Articles

-

Is PV with energy storage calculated as DC or AC

Is PV with energy storage calculated as DC or AC

-

Energy storage system DC cabin and AC cabin

Energy storage system DC cabin and AC cabin

-

AC DC energy storage cabinet

AC DC energy storage cabinet

-

How much does flywheel energy storage cost

How much does flywheel energy storage cost

-

Sucre Aerospace Tower Communication Base Station Flywheel Energy Storage

Sucre Aerospace Tower Communication Base Station Flywheel Energy Storage

-

Flywheel energy storage saves carbon emissions

Flywheel energy storage saves carbon emissions

-

What is the communication base station flywheel energy storage to optical exchange

What is the communication base station flywheel energy storage to optical exchange

-

Flywheel energy storage vehicle is UPS

Flywheel energy storage vehicle is UPS

-

Bhutan power plant flywheel energy storage

Bhutan power plant flywheel energy storage

-

Flywheel Energy Storage in Manchester UK

Flywheel Energy Storage in Manchester UK

Commercial & Industrial Solar Storage Market Growth

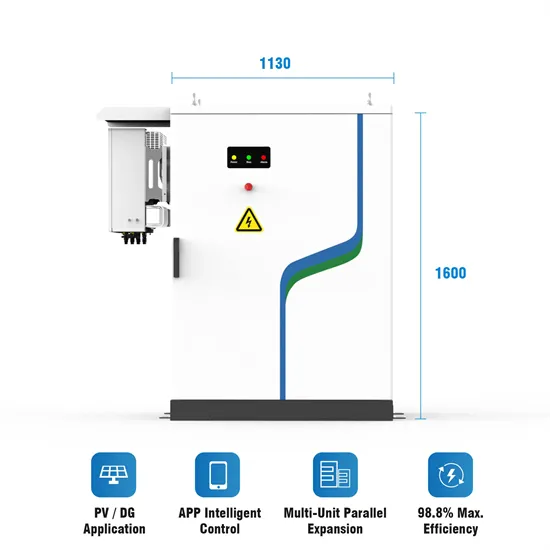

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.