Study on performance effects for battery energy storage

Feb 1, 2025 · This study utilizes numerical methods to analyze the thermal behavior of lithium battery energy storage systems. First, thermal performance indicators are used to evaluate the

Get Started

Multi-objective topology optimization design of liquid-based cooling

Feb 1, 2025 · Multi-objective topology optimization design of liquid-based cooling plate for 280 Ah prismatic energy storage battery thermal management

Get Started

difficulties in designing liquid cooling for energy storage cabinets

Home - Energy Storage Knowledge - Safety design of liquid refrigerated cabinets and liquid cooling plate design specifications Since this year, various energy storage companies have

Get Started

Principles of liquid cooling pipeline design

3 days ago · This article will introduce the relevant knowledge of the important parts of the battery liquid cooling system, including the composition, selection

Get Started

Field investigation on the performance of a novel hybrid cooling

Traditional liquid cooling systems of containerized battery energy storage power stations cannot effectively utilize natural cold sources and have poor temperature uniformity. To address these

Get Started

Study on uniform distribution of liquid cooling pipeline in

Mar 15, 2025 · Designing a liquid cooling system for a container battery energy storage system (BESS) is vital for maximizing capacity, prolonging the system''s lifespan, and improving its

Get Started

What are the heat dissipation issues of energy

Jun 11, 2024 · The primary causes of heat dissipation difficulties in energy storage cabinets stem from a mixture of inefficient component selection, poor

Get Started

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

Get Started

Optimization and Energy Consumption Analysis of the Cooling

Dec 16, 2023 · The development of energy storage is an important element in constructing a new power system. However, energy storage batteries accumulate heat during repeated

Get Started

Thermodynamic analysis of hybrid liquid air energy storage

Jan 5, 2020 · As a promising solution for large-scale energy storage, liquid air energy storage (LAES) has unique advantages of high energy storage density and no geographical constraint.

Get Started

Thermal design and simulation analysis of an immersing liquid cooling

Indirect liquid cold plate cooling technology has become the most prevalent method for thermal management in energy storage battery systems, offering significant improvements in heat

Get Started

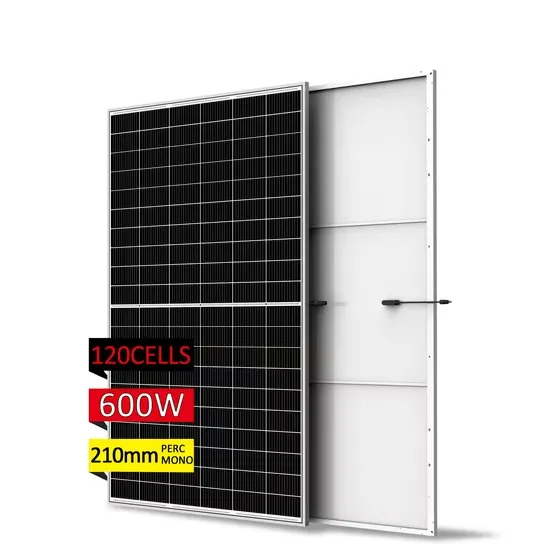

Innovative Applications and Advantage Analysis of Prismatic

Jul 29, 2024 · Prismatic battery modules have the faetures of efficient integration and modular design, optimized heat dissipation performance, and enhanced safety performance in energy

Get Started

Frontiers | Research and design for a storage

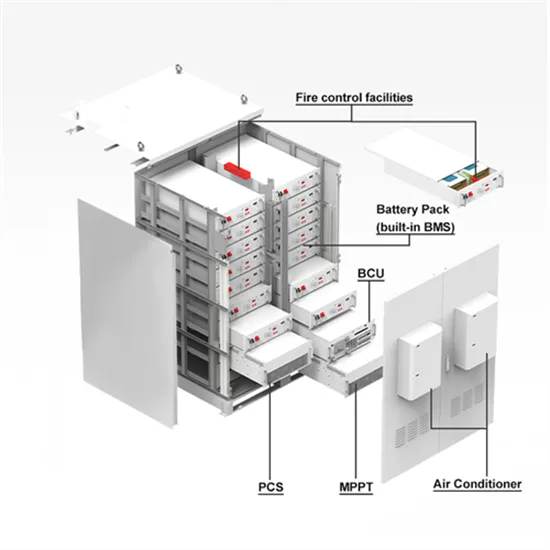

Aug 9, 2024 · Based on the device status and research into industrial and commercial energy storage integrated cabinets, this article further studies the

Get Started

Understanding Liquid-Cooled Energy Storage Cabinets: A

Jul 1, 2025 · Liquid-cooled energy storage cabinets are a significant advancement in the realm of electrical engineering, particularly in energy management systems. These cabinets play a

Get Started

Design and thermodynamic performance analysis of a new liquid

Jul 1, 2021 · Liquid CO2 energy storage system is currently held as an efficiently green solution to the dilemma of stabilizing the fluctuations of renewable power.

Get Started

The Evolution of Energy Storage Cabinets: Power Solutions

Aug 23, 2024 · Explore the advancements in energy storage cabinets, focusing on the integration of liquid cooling technology, enhanced energy management, cost savings, and future

Get Started

Design and off-design performance analysis of a liquid

Jun 25, 2023 · Nowadays, developing the renewable energy has become the worldwide consensus. Nevertheless, the intermittency and volatility of renewable electricity bring great

Get Started

液冷散热技术在电化学储能系统中的研究进展

Apr 1, 2024 · The findings indicate that liquid cooling systems offer significant advantages for large-capacity lithium-ion battery energy storage systems. Key

Get Started

Modelling and Thermodynamic Analysis of Small

Dec 14, 2020 · The intention of this paper is to model and analyse a small scale compressed air storage system useful for standalone and micro-grid applications. The economics of CAES is

Get Started

Technical difficulties of energy storage cabinets

Pumped Thermal Electricity Storage: A technology overview. Pumped Hydro Storage or Pumped Hydroelectric Energy Storage is the most mature, commercially available and widely adopted

Get Started

Energy, economic and environmental analysis of a combined cooling

Sep 10, 2024 · Indirect liquid cooling is currently the main cooling method for the cabinet power density of 20 to 50 kW per cabinet. An integrated energy storage batteries (ESB) and waste

Get Started

The difference between the six cooling systems of

The complexity of the review is based on the analysis of 250+Information resources. Various types of energy storage systems are included in the review. Technical solutions are associated

Get Started

liquid cooling energy storage system

Liquid cooling energy storage system management and control The control system gathers pressure and temperature data from sensors to regulate the

Get Started

The Ultimate Guide to Liquid-Cooled Energy

Jul 22, 2024 · Energy storage cabinets play a vital role in modern energy management, ensuring efficiency and reliability in power systems. Among

Get Started

Liquid-cooled Energy Storage Cabinet

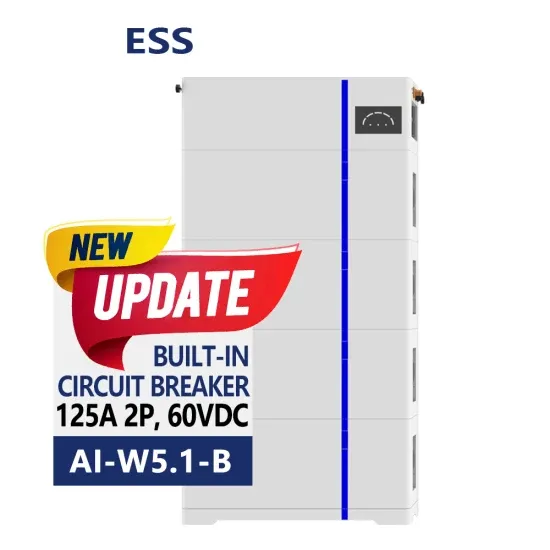

Commercial & Industrial ESSExcellent Life Cycle Cost • Cells with up to 12,000 cycles. • Lifespan of over 5 years; payback within 3 years. • Intelligent Liquid Cooling, maintaining a temperature

Get Started

difficulties of energy storage liquid cooling

Energy, exergy, and economic analyses of a novel liquid air energy A novel liquid air energy storage system is proposed. • Filling the gap in the crossover field research between liquid air

Get Started

What is the process for developing a liquid

Aug 13, 2025 · To develop a liquid cooling system for energy storage, you need to follow a comprehensive process that includes requirement analysis, design

Get Started

Structure optimization design and performance analysis of liquid

May 15, 2024 · The structural design of liquid cooling plates represents a significant area of research within battery thermal management systems. In this study, we aimed to analyze the

Get Started

Design of Dielectric Fluid Immersion Cooling System for

May 15, 2025 · Traditional battery thermal management systems (BTMS), such as air-based cooling and indirect liquid cooling using cold plates, often result in high thermal

Get Started

Energy, exergy, and economic analysis of cold energy storage

Jul 1, 2025 · This paper investigates the energy, exergy, and economic performance of both the charge and discharge processes of the energy storage system, as well as the overall

Get Started

Technical difficulties of energy storage cabinets

hnical Difficulties of Energy Storage Containers. Hydrogen is increasingly being recognized as a promising renewable energy carrier that can help to address the intermittency issues

Get Started

6 FAQs about [Analysis of Difficulties in Liquid Cooling Design of Energy Storage Cabinets]

Is indirect liquid cooling a viable solution for cabinet power density reduction?

Indirect liquid cooling is currently the main cooling method for the cabinet power density of 20 to 50 kW per cabinet. An integrated energy storage batteries (ESB) and waste heat-driven cooling/power generation system was proposed in this study for energy saving and operating cost reduction.

What is the total energy consumption of a liquid cooling data center?

The total energy consumption includes the energy consumptions of the cabinets, uninterruptible power supply (UPS), cooling system, lighting system, power transfer, and distribution system. The PUE of the liquid cooling data centers can usually be reduced to below 1.3 [6, 7].

Why do liquid cooling data centers need energy-saving retrofitting?

However, for places with high ambient temperatures like Shenzhen, its liquid cooling PUE may still be higher than 1.3, and this is why the local liquid cooling data centers need energy-saving retrofitting to meet local policies for PUE in Shenzhen.

How does ambient temperature affect a data center cooling system?

As both the operation status of the original data center and the proposed system are related to the ambient temperature, the system energy saving is heavily dependent on the ambient temperature. Relative humidity also has an influence on the temperature of the circulated cooling water, which further affects the cooling mode of the proposed system.

Can a liquid cooling data center drive adsorption refrigeration cycle?

Waste heat from a liquid cooling data center was utilized to drive an adsorption refrigeration cycle in Ref. , and the generated refrigeration capacity of the ARC was further used for air cooling. It was found that for a 350 kW water cooling system and a 50 kW air cooling system, the discounted payback period (DPB) was as low as 285 days.

How much energy is saved by 1000 cabinets?

Maximum energy saving reaches 90.8 GWh/year with 1000 cabinets. Maximum net present value reaches 998 million CNY. Huge energy consumption of data centers has become a concern with the demand for greater computing power. Indirect liquid cooling is currently the main cooling method for the cabinet power density of 20 to 50 kW per cabinet.

Related Articles

-

Industrial and commercial energy storage liquid cooling design solution

Industrial and commercial energy storage liquid cooling design solution

-

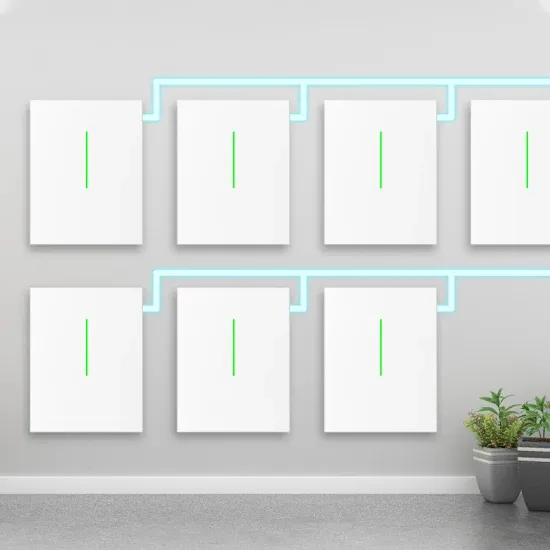

Multiple liquid cooling energy storage outdoor cabinets connected in parallel

Multiple liquid cooling energy storage outdoor cabinets connected in parallel

-

Mozambique Liquid Cooling Energy Storage Container Price

Mozambique Liquid Cooling Energy Storage Container Price

-

Türkiye Izmir Liquid Cooling Commercial Energy Storage Equipment Company

Türkiye Izmir Liquid Cooling Commercial Energy Storage Equipment Company

-

Fiji Liquid Cooling Energy Storage Container Supplier

Fiji Liquid Cooling Energy Storage Container Supplier

-

Communication base station flywheel energy storage 5MWH liquid cooling operation

Communication base station flywheel energy storage 5MWH liquid cooling operation

-

Energy storage liquid cooling and water cooling

Energy storage liquid cooling and water cooling

-

5mwh energy storage liquid cooling

5mwh energy storage liquid cooling

-

Cape Verde CRRC Energy Storage Liquid Cooling Company

Cape Verde CRRC Energy Storage Liquid Cooling Company

-

Zagreb liquid cooling energy storage equipment manufacturer

Zagreb liquid cooling energy storage equipment manufacturer

Commercial & Industrial Solar Storage Market Growth

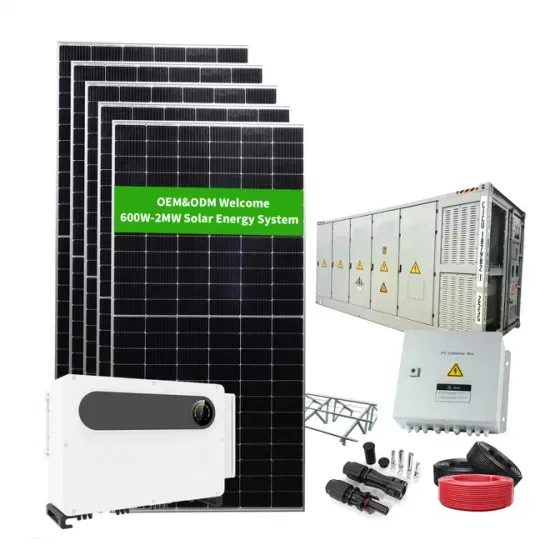

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.