Lithium Battery Guide

Nov 21, 2024 · This guide provides scenario-based situations that outline the applicable requirements that a shipper must follow to ship packages of lithium cells and batteries in

Get Started

Shipping Lithium-Ion Batteries: UN3480

4 days ago · Learn the essential regulations for shipping lithium-ion batteries (UN3480 & UN3481) to ensure safety and compliance in your logistics

Get Started

End-of-Life and Damaged Battery Shipping:

Apr 1, 2025 · Further on, batteries headed for recycling may have different sets of requirements (limited state of charge, marking and labelling, packaging, etc.)

Get Started

Extended Battery Producer Responsibility (EPR) Framework

Aug 7, 2025 · Scope The national battery EPR framework and accompanying Report to Congress will consider all battery chemistries (e.g., lithium-based, nickel-metal hydride, alkaline) and all

Get Started

Energy Storage Battery Packaging: A Step-by-Step Guide for

Feb 19, 2024 · Understanding Your Audience If you''re reading this, you''re probably part of the 72% of energy professionals who consider battery packaging the "make-or-break" factor in

Get Started

UN 3480, UN3481, UN3090, UN3091, UN3171, UN3536:

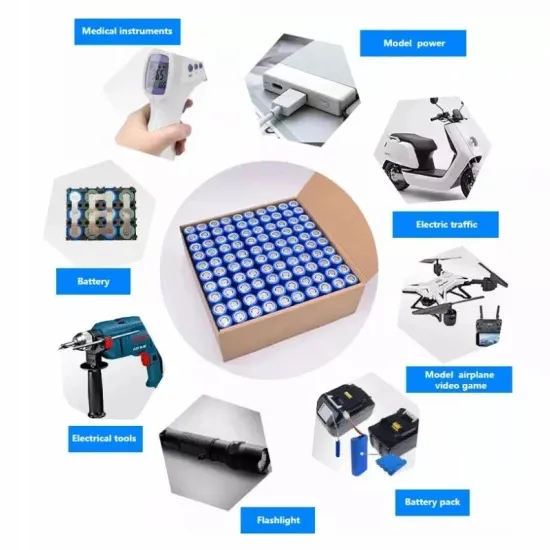

By Richie Lin Photo:CANVA Lithium battery products are omnipresent in our daily life. They are widely used in Consumer Electronics, Electric Vehicles (EVs), Energy Storage Systems,

Get Started

White Paper Summarizing Existing Battery Labeling Requirements

------- rather, they are meant to provide the necessary context to develop consistent voluntary battery labeling guidelines and education on safe use, handling, storage, disposal, and EOL

Get Started

energy storage new energy battery packaging requirements

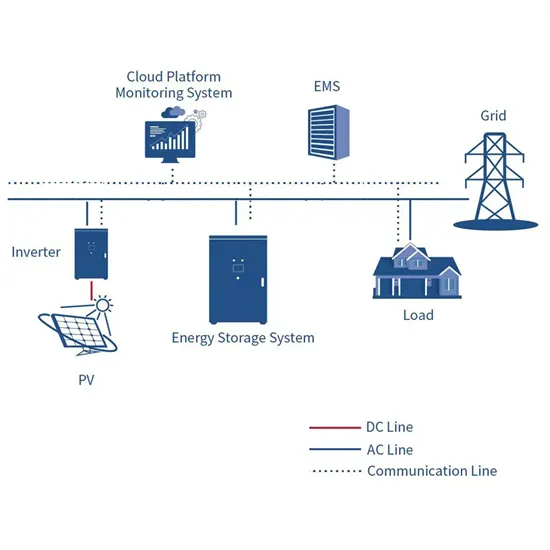

Battery Energy Storage Energy storage, and particularly battery-based storage, is developing into the industry''''s green multi-tool. With so many potential applications, there is a growing need for

Get Started

Energy storage battery packaging requirements and standards

Mechanical Design and Packaging of Battery Packs for intermittency affects all renewable energy resources. Use of battery packs to add an energy buffer and increase flexibility of the electric

Get Started

Battery Packaging Architectures: Materials

Jan 7, 2025 · Challenges surrounding battery packaging architecture include dealing with packaging space, thermal management, and optimizing battery

Get Started

Battery guidance document

Feb 3, 2025 · Although some lithium and sodium ion batteries are eligible for transportation as Section II and exempted from certain labelling, packing and documentation requirements,

Get Started

Energy storage box packaging standard requirements

size and weight load requirements of your project. The most common NEMA rating for solar and stationary battery boxes is NEMA 3R and all Fabricated Metals battery and energy storage

Get Started

White Paper Summarizing Existing Battery Labeling

Jan 15, 2025 · By developing new voluntary battery labeling guidelines, EPA seeks to increase consumer awareness of the presence of batteries in products and to empower consumers to

Get Started

Regulatory Requirements – Canadian Battery Association

Mar 3, 2025 · The CBA has worked with Federal and Provincial regulatory agencies to help members understand and comply with a wide variety of Federal and Provincial regulations that

Get Started

the latest requirements for energy storage battery packaging

Depending on the battery, the requirements for packaging (strong outer packaging, protection against short circuit, etc.) and shipping (road, rail, sea freight, airfreight, etc.) differ.

Get Started

Learn About the Different Types of Battery

Mar 28, 2025 · Proper packaging isn''t just about looks—it protects the battery from damage, prevents leaks, and ensures safe transport and storage. A

Get Started

What kind of packing tape is used for energy

Sep 17, 2024 · Moreover, PE packing tape is available in various thicknesses and adhesive strengths, making it adaptable for different packaging requirements.

Get Started

Battery Shipping: Classification, Best Practices,

Apr 4, 2024 · Other battery types – like lead-acid, nickel-metal hydride (NiMH), and dry cell batteries — may fall under different categories, but all require

Get Started

Energy Storage Battery Packaging: A Step-by-Step Guide for

Feb 19, 2024 · If you''re reading this, you''re probably part of the 72% of energy professionals who consider battery packaging the "make-or-break" factor in energy storage systems. Whether

Get Started

What Are the Safety Guidelines for Transporting UN3480 Lithium Batteries?

Dec 11, 2024 · UN3480 refers to the classification of lithium-ion batteries that are shipped on their own, and understanding its regulations is crucial for ensuring safe transportation. This article

Get Started

Technical requirements for energy storage battery

This paper gives a brief overview of battery packaging concepts, their specific advantages and drawbacks, as well as the importance of packaging for performance and cost.

Get Started

The Complete Guide to Lithium Ion Battery

Jan 11, 2024 · Prototype lithium ion batteries are also exempt from testing and record-keeping requirements but must meet standard packaging

Get Started

Energy storage battery product packaging requirements and

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Get Started

technical requirements and standards for energy storage battery packaging

By interacting with our online customer service, you''ll gain a deep understanding of the various technical requirements and standards for energy storage battery packaging featured in our

Get Started

Better battery packaging with polycarbonate

The future of transport will be powered by batteries. To accelerate adoption, energy storage must be safe, reliable, and ensure full circularity: battery

Get Started

BEST PRACTICE GUIDE: BATTERY STORAGE EQUIPMENT

Jun 15, 2025 · Compliant to Best Practice Guide for Battery Storage Equipment – Electrical Safety Requirements – version 1 - Pre-assembled integrated battery energy storage system

Get Started

Understanding Battery Pack Technology: Key Components,

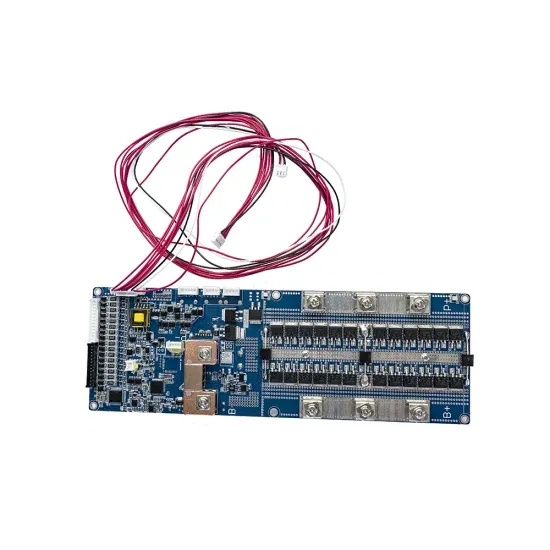

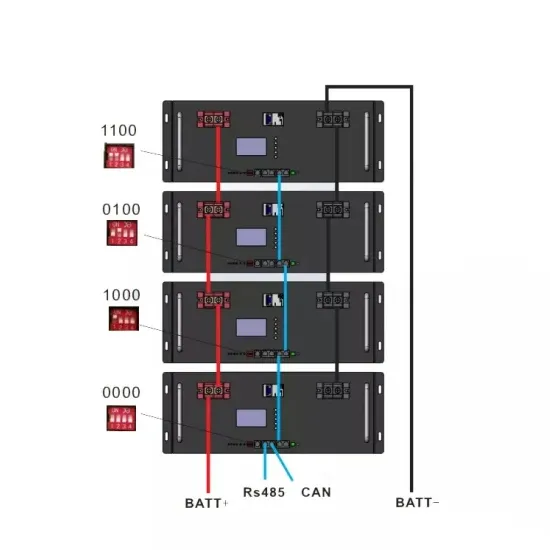

Mar 14, 2025 · Battery pack technology is a sophisticated system integrating battery cells, a battery management system (BMS), structural components, and thermal management

Get Started

Mastering the Battery Pack Assembly Process: A

Jan 23, 2025 · Conclusion The battery pack assembly process is a sophisticated and highly specialized field that underpins the success of modern energy

Get Started

EU Battery Regulation 2023/1542 and WEEE, ELV, andRoHS

Mar 15, 2025 · Broader Regulatory Context Circular Economy: The Battery Regulation aligns with the EU Circular Economy Action Plan, intersecting with WEEE, ELV, and RoHS through

Get Started

energy storage battery packaging requirements and standards

Here''s some videos on about energy storage battery packaging requirements and standards Battery Storage, how to maximise it, Octopus Energy Short clip on how to maximise

Get Started

6 FAQs about [Energy storage battery packaging requirements]

What are the new packaging requirements for lithium ion batteries?

Revised Packing Instructions: More stringent requirements for UN-certified packaging, capable of withstanding specific drop tests. State of Charge (SoC) Emphasis: Increased scrutiny on the SoC for standalone lithium-ion battery shipments, with a general requirement not to exceed 30% of rated capacity.

What are the requirements for packaging a battery?

• Each outer package must be a strong outer packaging and capable of withstanding a 1.2 meter drop test, in any orientation, without damage to the cells or batteries, without shifting that would allow battery-to-battery contact, and without release of the contents. They are not required to be packaged in UN specification packaging.

What are the requirements for external battery storage equipment?

y standards None applicable at present.3.2.3 Separate specific requirementsExternal enclosure of the battery storage equipment is metallic material having a minimum thickness not less than 0.20 mm at any point, or is a polymeric material classified as 5VA according to IEC 60695-11-20:2015 (provided that the test sample used f

Why is proper battery packaging important?

Proper packaging isn’t just about looks—it protects the battery from damage, prevents leaks, and ensures safe transport and storage. A poorly packaged battery can lead to chemical leaks, short circuits, or even fires. That’s why industry standards dictate specific rules for packaging different battery types.

Do I need a performance packaging for a lithium battery?

However, if the package contains no more than 2.5 kg of lithium metal cells or batteries, UN performance packaging is not required when the package displays both the Lithium Battery Mark and the Class 9 Lithium Battery label. See 173.185(c)(5)(i) for details. • Damaged, defective, or recalled lithium batteries are forbidden from air transport.

What are the shipping guides for lithium cells & batteries?

For the purposes of this document, the ways to describe and configure packages of lithium cells and batteries, including smaller cells and batteries, are divided between ten distinct, standalone shipping guides. The shipping guides are numbered Guide 01 - Guide 10.

Related Articles

-

Installation requirements for battery energy storage system at Vilnius communication base station

Installation requirements for battery energy storage system at Vilnius communication base station

-

Energy storage battery cabinet storage environment requirements

Energy storage battery cabinet storage environment requirements

-

Fire protection requirements for lithium battery energy storage cabinets

Fire protection requirements for lithium battery energy storage cabinets

-

What are the requirements for energy storage battery transportation

What are the requirements for energy storage battery transportation

-

Dubai energy storage battery export fba warehouse requirements

Dubai energy storage battery export fba warehouse requirements

-

Nigeria new energy battery storage box direct sales

Nigeria new energy battery storage box direct sales

-

Mongolia Energy Storage Cabinet Battery Project Address

Mongolia Energy Storage Cabinet Battery Project Address

-

What is the battery frequency of the communication base station battery energy storage system

What is the battery frequency of the communication base station battery energy storage system

-

Telecom Energy Storage Clean Energy Storage Battery Cabinet Structure

Telecom Energy Storage Clean Energy Storage Battery Cabinet Structure

-

12v150ah photovoltaic energy storage battery

12v150ah photovoltaic energy storage battery

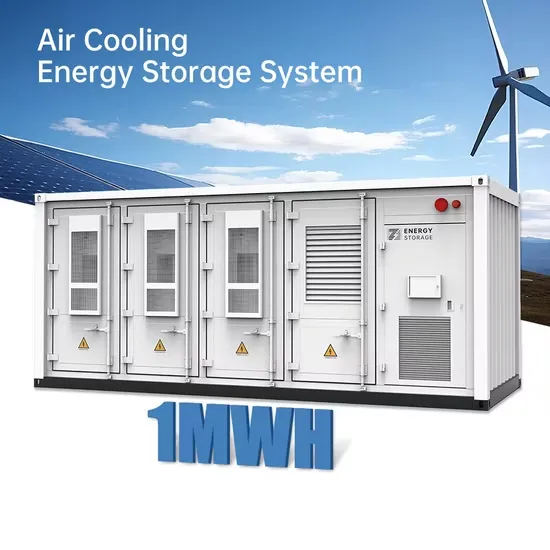

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.