Solis Seminar 【Episode 39】: How to Quickly and Effectively

Jan 27, 2022 · Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the PV+ to ground and PV- to ground of each string.

Get Started

Using the Piecewise Method to Check the PV

Jul 20, 2023 · Troubleshooting Disconnect the DC switch of each PV string connected to the inverter. After 10 minutes, remove each PV string from the

Get Started

Photovoltaic inverter grounding

What is effective grounding in photovoltaic(PV) systems? Effective grounding in photovoltaic (PV) systems is the creation of a low-impedance reference to ground at the AC side of the inverter-

Get Started

Measuring the Insulation Resistance of PV Strings to the Ground

Before connecting PV strings to the inverter, ensure that the insulation resistance of each PV string to the ground is normal. The following figure shows the measuring method. Connect the

Get Started

Troubleshoot Ground Fault on Huawei SUN2000 Inverters

Jun 3, 2019 · If the inverter stops production and the Alarm ID 313-1 (Low Insulation Resistance) or 318-1 (Abnormal Residual Current) is displayed in the Smartlogger1000&2000 or SUN2000

Get Started

Best Practices in PV System Ground Fault Testing

Sep 18, 2023 · Voltage Measurements: Once the string conductors are safely isolated, voltage measurements can be recorded and compared. Using a

Get Started

Do You Need To Ground An Inverter? (Safe

Apr 4, 2022 · What Should Be Ground on Your PV System All the components in your system should be grounded to the same single-point grounding

Get Started

Solis Seminar 【Episode 55】: Using the piecewise method

Aug 28, 2023 · After 10 minutes, remove each PV string from the inverter and use a multi-meter to measure the voltage of the PV+ to ground and PV- to ground of each string. This will identify

Get Started

How to find and repair ground faults in solar PV systems

May 16, 2024 · Understand expected values before you begin need to know what mea-surement values to expect — specifically voltage. Module pen circuit voltage (Voc) can be found on the

Get Started

Different voltages for strings and MPPT

Feb 9, 2023 · String 1 is facing South and String 2 is facing West, so their production is not symmetric, it is actually the opposite, I would like to connect string 1 and string2 to the same

Get Started

Solis Seminar 【Episode 39】: How to Quickly

Feb 9, 2022 · Troubleshooting: Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the

Get Started

Solis Seminar 【Episode 39】: How to Quickly and Effectively

Feb 25, 2022 · If the string voltage of the PV+/PV- terminal to ground is unbalanced, (for example the voltage value of one polarity to ground is 0 V or close to 0 V, and the other polarity to

Get Started

A Complete Guide to String Inverters

A string inverter is an aggregated device primarily designed to process the DC output of multiple interlinked solar panels into practical AC energy. These

Get Started

Boost Efficiency and Save on BoS with Fixed String Voltage

Aug 7, 2025 · When we tell engineers and EPCs that our inverters use "fixed string voltage," we often get puzzled looks. But once we walk them through the concept, the benefits become

Get Started

Grounding schemes for various Inverters

Feb 28, 2025 · Grounding schemes for various Inverters This is a collection of grounding schemes for various inverters. It is a collection of information gathered from hands-on experience,

Get Started

How to find and repair ground faults in solar PV systems

May 16, 2024 · Understand expected values before you begin Before testing to identify the location of a ground fault, you need to know what mea-surement values to expect —

Get Started

Inverters: A Pivotal Role in PV Generated Electricity

Dec 15, 2021 · Inverter segments String inverters are the largest segment if you include utility, residential 3-phase and single phase string inverters Central Inverters gaining capability with

Get Started

Checking the PV System for Ground Faults

Apr 15, 2019 · Do not connect PV strings with ground faults to the inverter. Ensure that no voltage is present and wait five minutes before touching any parts of the PV system or the product.

Get Started

Solis Seminar 【Episode 39】: How to Quickly

Feb 11, 2022 · 3) The insulation layer of the DC cable connecting the string to the inverter is damaged and connected to the ground. Troubleshooting:

Get Started

Dangerous voltage between positive and ground (structure)

Aug 18, 2025 · I checked the negative wire for any chaffing or anywhere that could cause a ground fault and found nothing. I then disconnected the -ve from the inverter and the voltage

Get Started

Technical Information

Jun 13, 2025 · For medium-voltage transformers of the YNyn type (star-star connection with outgoing neutral conductors on both the primary and secondary sides), both neutral

Get Started

Best Practices in PV System Ground Fault Testing

Sep 18, 2023 · To isolate the fault, best practice is generally to start at the inverter level, then segment the system to narrow the tests to the combiner and

Get Started

Measuring the Insulation Resistance of PV Strings to the Ground

Connect the positive and negative output connectors of a PV string to a branch cable, and use an insulation resistance tester to test the insulation resistance of the PV string cable to the

Get Started

Solis Seminar 【Episode 39】: How to Quickly and Effectively

Jan 27, 2022 · Troubleshooting: Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the PV+ to ground and PV- to

Get Started

Earth Faults in PV Systems: Identification, Safety,

Measure negative-to-ground: Reading: 809.92VDC. Divide the voltage readings by the module Voc: Result: The fault is located in the positive sub-array

Get Started

Using the Piecewise Method to Check the PV

Jul 20, 2023 · Under normal circumstances, the absolute value of the voltage to ground at the positive or negative terminals should be between 100~1000 V,

Get Started

Solar Ground-Fault: How to Identify, Locate, and

Testing each one in free-air, we found the faulted string by identifying which one showed voltage to ground, and left the other disconnected to remove it from

Get Started

Voltage between array negative and ground

4 days ago · I recently wired up a combiner box, where several strings of panels come together, and are combined into a single set of +, -, G wires that run to the inverter. While poking around

Get Started

Solar Inverter String Design Calculations

3 days ago · Support Solar Articles Solar Inverter String Design Calculations For many new to photovoltaic system design, determining the maximum number

Get Started

Troubleshooting Ground Faults for Solar

2 days ago · The next step is to take voltage measurements; positive to ground, negative to ground, and open circuit voltage (positive to negative). Record

Get Started

What is Negative Grounding in Solar Inverters?

Jun 16, 2024 · A solar inverter breaking down can hit an Indian home with a ₹25,000 repair bill. This is why making sure your solar system is grounded

Get Started

100 kW-480 V, 1500 Vdc String Inverters for North America

Jun 5, 2025 · CPS SCH100KTL-DO/US-480 The CPS 100 kW-480 V three-phase string inverters are designed for ground-mount applications with 480 Vac service voltage. The units are high

Get Started

Grounding Techniques to Prevent Inverter

Apr 20, 2017 · If the voltage appears between the AC and DC side of the invterter, it will fail. The average designed withstand voltage of solar inverters is 1750

Get Started

2023 Update: How to Calculate PV String Size —

Nov 15, 2023 · The inverter''s "maximum system voltage" sets the voltage limit for the maximum string length, typically either 1000 Vdc or 1500 Vdc for

Get Started

6 FAQs about [Inverter string voltage to ground]

Does a PV inverter have a ground fault?

To facilitate a low-resistance connection between all the materials, all PV systems should include an equipment grounding system that bonds all the metallic frames and components. If a ground fault occurs, the current from that fault therefore has a direct path to the PV inverter and to the ground-fault detector.

Can a PV inverter be touched?

Touch the cables of the PV array on the insulation only. Do not touch any parts of the substructure or frame of the PV array. Do not connect PV strings with ground faults to the inverter. Ensure that no voltage is present and wait five minutes before touching any parts of the PV system or the product.

How do I know if my inverter has a ground fault?

inverter. For these systems, you can skip insulation resistance testing. Use the voltage testing procedure ou lined earlier, because you’ll know which inverter has the ground f ult.An intermittent ground fault appears only under specific conditions. Insulation esistance testing can often identify PV string circuits with such faults

How to test energized DC PV string circuits with ground faults?

riate PPE.How to test energized DC PV string circuits with ground faultsmethodical testing procedure and most important, safely.Understand expected values before you beginBefore testing to identify the location of a ground fault, you need to know what mea-surement values to expect — specifically voltage. Module

What happens if you leave a ground fault in a solar PV string?

If left undetected, ground faults can lead to inverter shutdowns, loss of system yield, or even fire. In this article, we’ll show you how to locate a ground fault in a solar PV string using only a multimixer, a basic understanding of voltage behaviour, and a method proven in real-world installations.

How to find a ground fault in a PV string circuit?

wire nut or tape to prevent it from a cing and creating a safety hazard.Connect the black test ead to ground. Run the insulation resistance test an record the results.Repeat the test on other conductors in the cir-cuit. I fault.How to locate a ground fault in a PV string circuit by the numbersA PV string circuit without a ground fault will

Related Articles

-

Does the inverter have ground voltage

Does the inverter have ground voltage

-

Inverter voltage to ground safety

Inverter voltage to ground safety

-

Ultra-high voltage photovoltaic inverter

Ultra-high voltage photovoltaic inverter

-

Inverter voltage transformer

Inverter voltage transformer

-

The voltage of the newly purchased inverter is low

The voltage of the newly purchased inverter is low

-

Will the voltage of the inverter flow back to the battery

Will the voltage of the inverter flow back to the battery

-

Low voltage inverter 220v to 36v

Low voltage inverter 220v to 36v

-

Inverter voltage hysteresis

Inverter voltage hysteresis

-

Does the inverter capacitor increase the voltage

Does the inverter capacitor increase the voltage

-

Voltage inverter DC 110v to AC

Voltage inverter DC 110v to AC

Commercial & Industrial Solar Storage Market Growth

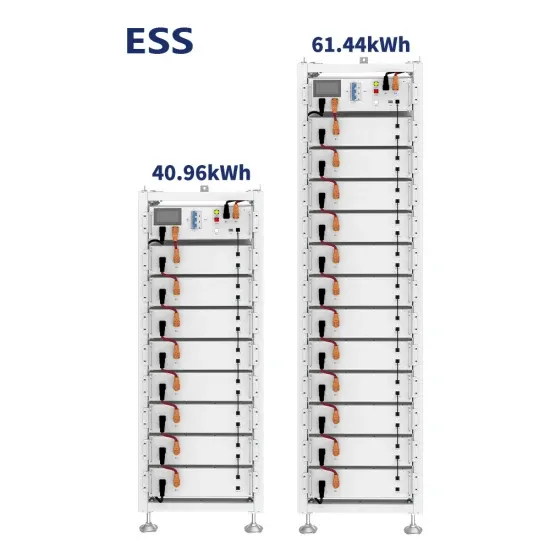

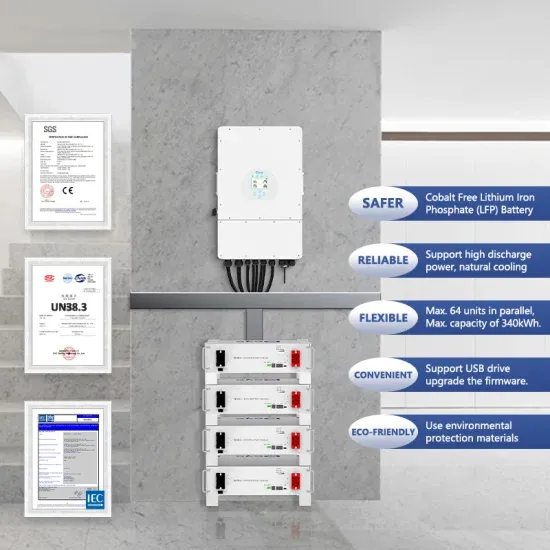

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.