Fabrication of Uranium-Plutonium Mixed Nitride Fuel

Aug 17, 2023 · Four He-bonded fuel pins containing uranium-plutonium mixed nitride pellets were fabricated for the irradiation tests in JMTR, aiming at understanding the irradiation behavior

Get Started

Physics:MOX fuel

Jul 21, 2024 · Mixed oxide fuel, commonly referred to as MOX fuel, is nuclear fuel that contains more than one oxide of fissile material, usually consisting of plutonium blended with natural

Get Started

Enriched Uranium: What is it and what is it for?

Jun 18, 2019 · Currently, uranium-235 is the main fissile material used in nuclear power plants and in some types of nuclear weapons such as the atomic bomb.

Get Started

Plutonium disposition in the BN-600 fast-neutron reactor at

Sep 1, 1998 · The BN-600 reactor is currently licensed by the Russian Federal Nuclear and Radiation Safety Authority (GOSATOMNADZOR or GAN) to operate with 18 fuel

Get Started

Banning Plutonium Separation

Aug 9, 2022 · France uses its separated plutonium, diluted with depleted uranium, in "mixed-oxide" (MOX) fuel to replace about 10% of the low-enriched-uranium fuel used by its

Get Started

Plutonium Power-Up: Fueling the Future with

May 16, 2025 · MOX Fuel Fabrication: MOX fuel can be manufactured by grinding uranium oxide and plutonium oxide together and compacting the mix to form

Get Started

Frequently Asked Questions About Mixed Oxide Fuel | NRC.gov

Aug 27, 2020 · The mixed oxide fuel proposed by Shaw AREVA MOX Services (formerly Duke COGEMA Stone & Webster (DCS)) is a blend of plutonium dioxide and depleted uranium

Get Started

Backgrounder: Plutonium.

Aug 8, 2025 · Plutonium-238 has been used to power batteries for some heart pacemakers, as well as provide a long-lived heat source to power NASA space missions. Like uranium,

Get Started

Safety of Uranium and Plutonium Mixed Oxide

Jun 11, 2025 · It describes the actions, conditions and procedures for meeting safety requirements and deals specifically with the handling, processing and

Get Started

Plutonium In Nuclear Power Plants

Understanding Plutonium Plutonium is a synthetic element with the atomic number 94 and symbol Pu. It is created through the process of nuclear reactions, specifically by the irradiation of

Get Started

MOX, a fuel assembly made from recycled

A chemical workshop separates the recyclable materials from the final, non-usable waste. At the end of these operations, 96% of the material is

Get Started

MOX fuel tests for VVER reactors under way

Jun 28, 2023 · Testing has begun on VVER-type fuel elements with uranium-plutonium mixed-oxide fuel in the MIR research reactor. Based on the results

Get Started

Managing the UK Plutonium Stockpile

Sep 14, 2016 · Four options for plutonium management are outlined in this briefing: indefinite storage at Sellafield; reuse as fuel in UK nuclear power plants; combining the plutonium with

Get Started

aten13001

Sep 1, 2021 · REMIX is a mixed uranium-plutonium oxide fuel based on an unseparated mixture of uranium and plutonium recycled from spent nuclear fuel with native or regenerated uranium

Get Started

Physics 1320 exam 3 Palomino Flashcards | Quizlet

b 8) A nuclear power plant is very similar to A) any conventional power plant, but with uranium as fuel. B) a photovoltaic solar cell power plant. C) nuclear bombs, but with more control. D) all of

Get Started

Mixed Oxide Fuels

Mixed oxide (MOX) fuel is a blend of reprocessed uranium, plutonium, and depleted uranium, which behaves similarly to the enriched fresh uranium feed for which most nuclear reactors

Get Started

2011 Nuclear Power Plant Sourcebook: Mixed Oxide Fuel (MOX), Plutonium

Mar 14, 2011 · Mixed oxide fuel (MOX), a nuclear fuel containing uranium and plutonium and used in the Fukushima Daiichi Reactor 3 in Japan, is fully covered in this authoritative collection of

Get Started

Pluthermal reactor dream for Japan still an

Dec 12, 2020 · Years ago, pluthermal energy was viewed as a dream way for Japan to generate electricity with nuclear power plants using plutonium

Get Started

Some fuels never learn. US Energy Department

Sep 14, 2022 · One obvious way to get rid of separated plutonium would be to mix it with depleted uranium to make "mixed-oxide" (MOX) fuel energetically

Get Started

Neutronic investigation of VVER-1000 assembly with mixed plutonium

Jul 29, 2025 · Plutonium accumulation from the operation of nuclear power plants presents a critical challenge for nuclear energy management, particularly due to the high decay heat and

Get Started

Thermogravimetric study of mixed uranium-plutonium fuel

Aug 15, 2022 · The use of mixed uranium-plutonium nitride fuel in fast reactors allows for a breeding ratio (BR) ≈ 1.06 with a rejection of the uranium blanket as well as the possibility of

Get Started

MOX Fuel: A Powerful Mix of Energy and

Apr 23, 2015 · In Europe, uranium and plutonium are recovered from the used nuclear fuel and reprocessed to manufacture new MOX fuel, a mixture of

Get Started

Neutronic investigation of VVER-1000 assembly with mixed plutonium

Jul 29, 2025 · Download Citation | Neutronic investigation of VVER-1000 assembly with mixed plutonium–uranium nitride fuel | Plutonium accumulation from the operation of nuclear power

Get Started

Use of remix spent mixed fuel plutonium in the

Jun 20, 2023 · The VVER-1000 thermal neutron reactor can operate on mixed uranium-plutonium fuel with a content of reactor-grade plutonium up to 5%

Get Started

Nuclear fuel : Uranium and Plutonium | by GlenQ | Medium

Oct 20, 2018 · N uclear fuel is the substance in the reactor that undergo a reaction called fission to produce energy in the form of heat. The most commonly found nuclear fuel would be

Get Started

Thermogravimetric study of mixed uranium-plutonium fuel

Aug 15, 2022 · The present paper studies the behaviour of mixed uranium-plutonium nitride nuclear fuel (MNIT fuel) at high temperatures (up to 2400 K) in a helium flow by

Get Started

MOX fuel

Mixed oxide, or MOX fuel, is a blend of oxides of plutonium and natural uranium, reprocessed uranium, or depleted uranium which behaves similarly (though not identically) to the low

Get Started

License for world''s first production line of

May 22, 2024 · "Rosatom has obtained an operation license for the world''s first production line for innovative mixed uranium-plutonium nitride (MUPN) fuel," a

Get Started

Managing nuclear materials and spent fuels

Apr 8, 2015 · We need to ensure the safe, secure and cost-effective lifecycle management of nuclear materials and spent fuels.

Get Started

6 FAQs about [Nassau photovoltaic power plant uranium-plutonium mixed fuel]

What uranium-plutonium oxide fuel?

REMIX is a mixed uranium-plutonium oxide fuel based on an unseparated mixture of uranium and plutonium recycled from spent nuclear fuel with native or regenerated uranium enriched in 235U to 19.75%. The use of such a mixture will reduce the consumption of enriched uranium by about 25% [13–17].

Can uranium and plutonium be used in VVER?

A new REMIX fuel is proposed in order to use plutonium in VVER – a mixed uranium-plutonium fuel, obtained from an unseparated mixture of uranium and plutonium separated during the regeneration of spent VVER fuel with the addi-tion of enriched uranium.

Can uranium-plutonium oxide fuel be used in Next-Generation Fast reactors?

The use of conventional mixed uranium-plutonium oxide fuel is also not excluded in next-generation fast reactors, but most promising is the introduction of a new, dense, mixed urani-um-plutonium nitride fuel that has not been previously used in power reactors. The reprocessing of BN-800 spent fuel has not yet been performed.

When will uranium-plutonium oxide fuel be produced?

The second stage of the experimental demonstration center for the production of initial oxides suitable for the fabrication of mixed uranium-plutonium oxide fuel and/or REMIX fuel, fuel based on an unseparated unenriched mixture of reprocessed uranium and uranium-enriched plutonium, is to be commissioned in 2021 .

Can plutonium be used in nuclear weapons?

The process of converting the fissile material into MOX fuel renders the plutonium less attractive for use in nuclear weapons. In some countries, MOX fuel is manufactured by recycling plutonium from spent nuclear fuel. That is not the case in the proposed MOX program in the U.S.

Can separated plutonium be used as a fuel for nuclear power plants?

Despite decades of failed attempts around the world to make separated plutonium an economic fuel for nuclear power plants, the United States Energy Department is once again promoting the recycling of separated plutonium in the fuel of “advanced” reactor designs.

Related Articles

-

Eastern European Photovoltaic Power Plant Generators

Eastern European Photovoltaic Power Plant Generators

-

Power plant photovoltaic panel size

Power plant photovoltaic panel size

-

Bangkok Photovoltaic Power Plant Generator Set

Bangkok Photovoltaic Power Plant Generator Set

-

Clean photovoltaic energy for Ethiopian power plant

Clean photovoltaic energy for Ethiopian power plant

-

Photovoltaic panel power plant in the Democratic Republic of Congo

Photovoltaic panel power plant in the Democratic Republic of Congo

-

Clean photovoltaic energy at Riyadh power plant

Clean photovoltaic energy at Riyadh power plant

-

Latvian photovoltaic energy storage power supply production plant

Latvian photovoltaic energy storage power supply production plant

-

China Solar Photovoltaic Power Plant On-site Energy

China Solar Photovoltaic Power Plant On-site Energy

-

What are the two parts of a hybrid photovoltaic power station

What are the two parts of a hybrid photovoltaic power station

-

Lusaka photovoltaic inverter production plant

Lusaka photovoltaic inverter production plant

Commercial & Industrial Solar Storage Market Growth

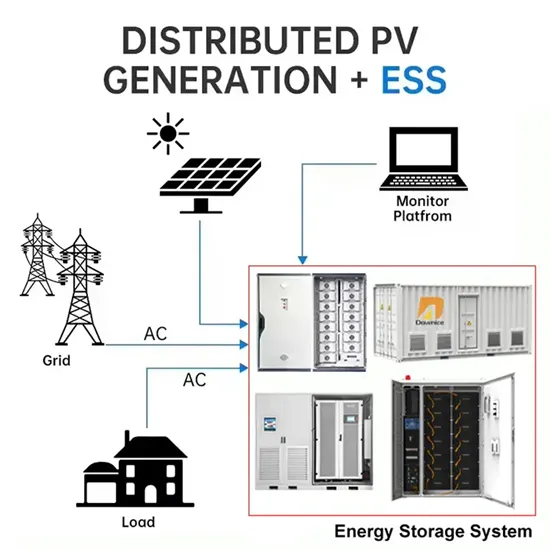

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.