Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · This reference design focuses on an FTM utility-scale battery storage system with a typical storage capacity ranging from around a few megawatt-hours (MWh) to hundreds of

Get Started

eastcoastpower

Battery Energy is an interdisciplinary journal focused on advanced energy materials with an emphasis on batteries and their empowerment processes. Mentioning: 6 - In recent years, the

Get Started

Lithium Iron Phosphate Battery Packs: Powering the Future

Apr 22, 2025 · The cathode of a LiFePO₄ battery pack is composed of lithium iron phosphate, which has an olivine - type crystal structure. This structure consists of a three - dimensional

Get Started

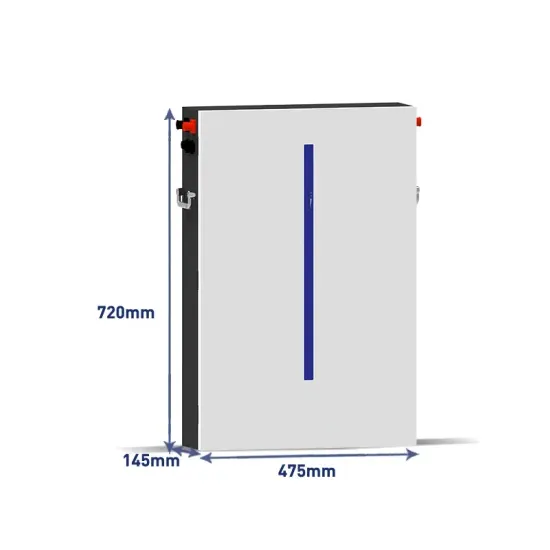

Lithium iron phosphate battery cabinet structure diagram

This circuit of single-cell LiFePO4 (lithium iron phosphate) battery charger is based on an LM358 operational amplifier (op-amp) and a couple of inexpensive and easy-to-get components.

Get Started

Fire protection design of prefabricated cabin

Aug 30, 2021 · In the battery prefabricated cabin, the energy storage battery modules are densely stacked, and the fully submerged cabinet-type

Get Started

Structural diagram of large energy storage battery cabinet

Lithium-ion battery energy storage system (BESS) has rapidly developed and widely applied due to its high energy density and high flexibility. However, the frequent occurrence of fire and

Get Started

DOE ESHB Chapter 3: Lithium-Ion Batteries

Mar 17, 2021 · Additionally, there are significant efforts to develop higher energy density variants of LFP such as LMFP (lithium manganese iron phosphate). This new composition preserves

Get Started

Lithium Iron Phosphate

Lithium iron phosphate is defined as an electrode material for lithium-ion batteries with the chemical formula LiFePO4, known for its high energy density, safety, long cycle life, and ability

Get Started

Comprehensive analysis of lithium iron

Jul 26, 2025 · Lithium iron phosphate battery (LiFePO4 batteries) are known for their high safety, long cycle life, and low cost, making them widely used in

Get Started

Optimum Selection of Lithium Iron Phosphate Battery Cells

Mar 20, 2025 · This paper presents a systematic approach to selecting lithium iron phosphate (LFP) battery cells for electric vehicle (EV) applications, considering cost, volume, aging

Get Started

EV Battery Pack Design: Structure, Safety

Oct 4, 2024 · Discover how EV battery pack design shapes electric vehicle performance with a focus on structure, safety, thermal management, and

Get Started

Lithium iron phosphate – Knowledge and References –

Lithium iron phosphate (LiFePO4 or LFP) is a type of cathode composition used in lithium-ion batteries that was developed to address the challenges of thermal and structural instability. It

Get Started

Thermal runaway and explosion propagation

This research can provide a reference for the early warning of lithium-ion battery fire accidents, container structure, and explosion-proof design of energy

Get Started

When Cells Become Structural Beams: Decoding

Mar 13, 2025 · Structural and Chemical Synergy: CTP 3.0 architecture designed to work with high-nickel manganese lithium iron phosphate cathodes. Smart

Get Started

The Role of Lithium Iron Phosphate (LiFePO4) in

Apr 18, 2025 · Discover how lithium iron phosphate (LiFePO4) enhances battery performance with long life, safety, cost efficiency, and eco-friendliness.

Get Started

The Ultimate Guide to Building a DIY LifePO4 Battery Box

Jan 22, 2024 · LifePO4, which stands for Lithium Iron Phosphate, is a type of rechargeable battery known for its high energy density, long cycle life, and excellent thermal stability.

Get Started

Lithium Iron Phosphate (LiFePO4): A

Nov 20, 2024 · Lithium iron phosphate (LiFePO4) is a critical cathode material for lithium-ion batteries. Its high theoretical capacity, low production cost,

Get Started

Fire Accident Simulation and Fire Emergency Technology

Sep 26, 2022 · In order to establish a reliable thermal runaway model of lithium battery, an updated dichotomy methodology is proposed-and used to revise the standard heat release

Get Started

Design and Application of Station Power Supply System for Lithium Iron

Nov 1, 2023 · Based on the engineering application design and development of the power supply system of lithium iron phosphate battery pack in the operation and maintenance mode, this

Get Started

Design and Application of Station Power Supply System for

Nov 1, 2023 · Based on the engineering application design and development of the power supply system of lithium iron phosphate battery pack in the operation and maintenance mode, this

Get Started

The origin of fast‐charging lithium iron

Jan 10, 2022 · The origin of the observed high-rate performance in nanosized LiFePO 4 is the absence of phase separation during battery operation at high

Get Started

A Guide to the 7 Main Lithium Battery Types –

Mar 21, 2025 · In this article, we will discuss in more depth the 7 types of lithium batteries are there, compare each type, and determine the best type for

Get Started

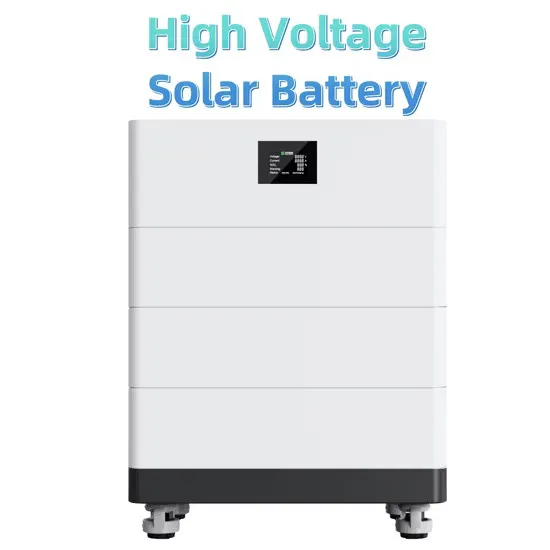

Deep Cycle Lifepo4 Battery Powerwall 10KWH

10KWH Battery Powerwall The home battery 10kwh 48v 200ah storage system is a wall mounted Lithium battery storage system. It is based on 16S2P 3.2v

Get Started

Structural Innovations in Lithium Iron Phosphate Battery

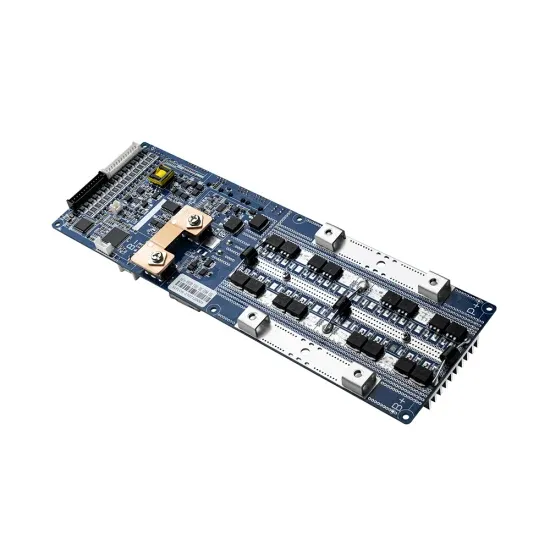

Aug 8, 2025 · The design of battery cell casings and assembly methods significantly impacts the overall structure and performance of lithium iron phosphate batteries. This includes

Get Started

Lithium iron phosphate energy storage battery structure

In order to study the thermal runaway characteristics of the lithium iron phosphate (LFP) battery used in energy storage station, here we set up a real energy storage prefabrication cabin

Get Started

Safety Analysis and System Design of Lithium Iron

Combined with the current background of the application of lithium iron phosphate batteries in substations, the system design of lithium iron phosphate batteries is discussed from many

Get Started

Structural Analysis of Lithium Iron Phosphate Battery Materials

Aug 8, 2025 · The structural analysis of lithium iron phosphate battery materials is a rapidly evolving field within the energy storage sector. The industry is in a growth phase, driven by

Get Started

significance energy storage power station lithium iron phosphate

As for the BAK 18650 lithium iron phosphate battery, combining the standard GB/T31484-2015 (China) and SAE J2288-1997 (America), the lithium iron phosphate battery was subjected to

Get Started

Fire Accident Simulation and Fire Emergency Technology

Sep 26, 2022 · In order to establish a reliable thermal runaway model of lithium battery, an updated dichotomy methodology is proposed-and used to revise the standard heat rel

Get Started

Application safety analysis and system design of lithium iron phosphate

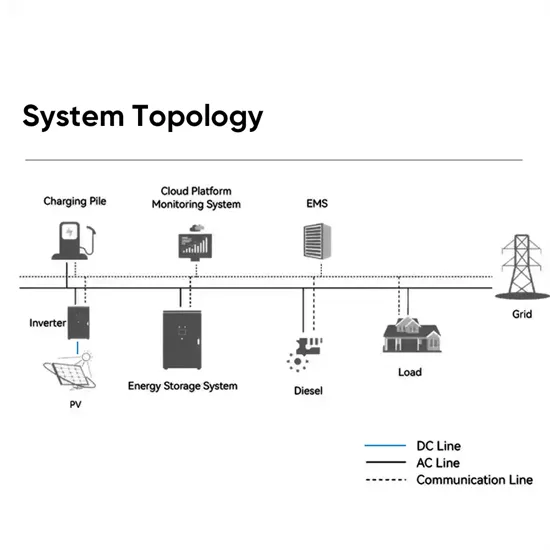

In order to solve the above problems, In this paper it is designed that a topology structure of lithium iron phosphate battery which connect in series to meet the voltage level and then

Get Started

design specification for lithium iron phosphate battery

Thermal runaway and explosion propagation characteristics of large lithium iron phosphate battery for energy storage station This research can provide a reference for the early warning of

Get Started

6 FAQs about [Structural design of lithium iron phosphate battery station cabinet]

Can lithium iron phosphate batteries be used in substations?

Combined with the current background of the application of lithium iron phosphate batteries in substations, the system design of lithium iron phosphate batteries is discussed from many aspects. It focuses on how to ensure its safety in order to improve the application effect of lithium iron phosphate batteries in substations.

Are 180 AH prismatic Lithium iron phosphate/graphite lithium-ion battery cells suitable for stationary energy storage?

This article presents a comparative experimental study of the electrical, structural, and chemical properties of large-format, 180 Ah prismatic lithium iron phosphate (LFP)/graphite lithium-ion battery cells from two different manufacturers. These cells are particularly used in the field of stationary energy storage such as home-storage systems.

What is the topology of lithium iron phosphate battery?

At present, the commonly used topology is mostly a combination of series and parallel. It can connect each battery pack in parallel and in series with the master control device. After adopting this topology, due to the differences in the parameters of each lithium iron phosphate battery cell, the battery circulation problem is also inevitable.

How does a lithium phosphate battery work?

chemical energy into electrical energy. During the charging process, the chemical reaction that occurs on the electrode is exactly the opposite of the former. Generally, lithium iron phosphate batteries use lithium iron phosphate as the positive electrode material.

What are the basic components of lithium iron phosphate batteries?

The basic components of lithium iron phosphate batteries are the same as other types of batteries. They are composed of positive and negative electrodes, separators, electrolyte, and casing. Among them, the positive and negative electrodes are composed of various active materials.

How to choose a lithium iron phosphate battery?

One is the design of the battery body. During the charging and discharging process of the lithium iron phosphate battery, it is inevitable that a certain amount of heat will be generated. For this reason, the thermal stability of the electrode and electrolyte materials is the primary consideration.

Related Articles

-

Environmentally friendly lithium iron phosphate battery station cabinet

Environmentally friendly lithium iron phosphate battery station cabinet

-

Which lithium iron phosphate battery station cabinet is better

Which lithium iron phosphate battery station cabinet is better

-

Lithium iron phosphate battery station cabinet upgrade

Lithium iron phosphate battery station cabinet upgrade

-

Lithium iron phosphate battery station cabinet communication power supply

Lithium iron phosphate battery station cabinet communication power supply

-

Lithium iron phosphate battery station cabinet structure

Lithium iron phosphate battery station cabinet structure

-

Sana outdoor lithium battery station cabinet design

Sana outdoor lithium battery station cabinet design

-

Base station lithium iron phosphate battery charging

Base station lithium iron phosphate battery charging

-

Outdoor lithium battery station cabinet design base station

Outdoor lithium battery station cabinet design base station

-

Series lithium battery station cabinet

Series lithium battery station cabinet

-

Prishtina lithium iron phosphate battery energy storage container price

Prishtina lithium iron phosphate battery energy storage container price

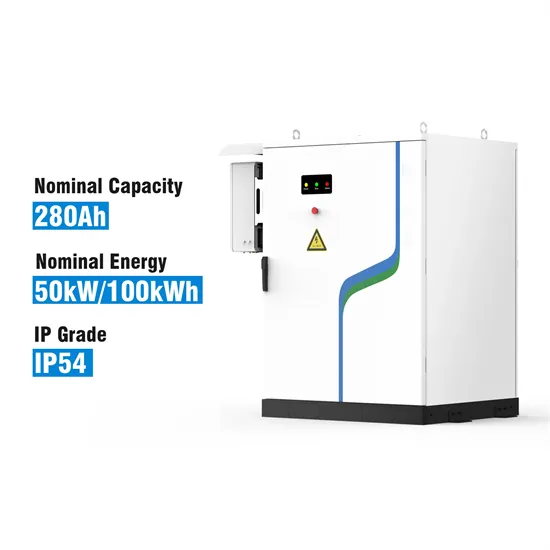

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.