How many photovoltaic panels are needed for 1gw

The size of the panels used in a 1 GW solar farm can range significantly depending on the type of panel chosen. For instance,a representative silicon model panel size for photovoltaic panels is

Get Started

Gigawatt

Discover what a gigawatt is, its usage in energy sectors, and why it''s critical in the context of renewable energy resources. Understand its etymology, historical significance, and practical

Get Started

China takes 97.9% of global wafer capacity in 2022

Jun 21, 2023 · Solar wafer production maintained a rapid growth trending in 2022, with a total capacity of 664 GW by the end of the year, up 60%, among which, the capacity for mono

Get Started

What does 1GW of solar energy mean? | NenPower

May 26, 2024 · 1GW of solar energy refers to a significant measure of power generation capacity produced by solar photovoltaic (PV) systems. 1. This

Get Started

Trina Solar launches 6.5-GW wafer factory in

Aug 28, 2023 · Chinese solar manufacturer Trina Solar Co Ltd (SHA:688599) announced the start of the manufacturing of 210-mm monocrystalline silicon

Get Started

China''s silicon wafer production capacity exceeds 900GW

Jun 21, 2024 · From the perspective of production layout, the silicon wafer production capacity of enterprises located in mainland China will be about 953.6GW by the end of 2023, accounting

Get Started

How Many Silicon wafers are Manufactured Annually?

Nov 12, 2023 · How Many Silicon Wafers Manufactured Annually? The number of silicon wafers produced each year is a key question in the semiconductor industry. The production of these

Get Started

Wafer-Based Solar Cell

Wafer-based solar cells refer to solar cells manufactured using crystalline silicon (c-Si) or GaAs wafers, which dominate the commercial solar cell industry and account for a significant portion

Get Started

The Production and Importance of Solar Wafers

May 7, 2024 · In just six years, solar PV installations globally jumped from 39 GW to 312 GW. This shows the solar sector''s rapid growth. Solar wafer production,

Get Started

The total global wafer production capacity was

Jul 2, 2024 · In 2023, the production capacity of monocrystalline silicon rods will increase by nearly 400GW compared with the end of 2022, and the production

Get Started

How many silicon wafers are there in 1 ton of

Apr 11, 2024 · In 1 ton of solar panels, the approximate number of silicon wafers is about 8,000 to 10,000 wafers, depending on the thickness and size of the

Get Started

Reliance on China made solar PV affordable but

Jul 12, 2022 · These policies fostered economies of scale and innovations that have made solar one of the most affordable forms of electrical generation,

Get Started

How Many Watts of Silicon Wafers Power Your Photovoltaic

Let''s start with a tasty metaphor: silicon wafers in solar panels are like pizza slices – their size, thickness, and quality determine how much energy you get. But instead of calories, we''re

Get Started

Gigawatt (GW) | Definition, Examples, & How

Jan 9, 2024 · A gigawatt is a unit of power equal to one billion watts. Discover what it is, how much energy it produces, and learn more about gigawatt projects.

Get Started

The solar cell wafering process

May 21, 2024 · The multi-wire sawing technique used to manufacture wafers for crystalline silicon solar cells, with the reduction of kerf loss currently representing about 50% of the silicon,

Get Started

What is Gigawatt?

Nov 17, 2023 · A gigawatt (GW) is a unit of power used in the field of electrical engineering and energy production, representing one billion watts or one

Get Started

Solar Wafers: Key to Efficient Solar Panels

Nov 3, 2023 · Explore the role of solar wafers in efficient solar panels, their types, manufacturing process, and contribution to reducing carbon emissions in the

Get Started

Silicon Wafer Manufacturing Process: Sand to

Jul 24, 2025 · What is Silicon? Silicon, Symbol Si, Atomic Number 14, is a chemical element and a very important component in the manufacturing of

Get Started

how many homes can 1 gigawatt power

A 1GWe plant produces 1GW of electrical power. What is the difference between onshore and offshore wind turbines? One gigawatt is roughly the size of two coal-fired power plants and is

Get Started

The total global wafer production capacity was

Jul 2, 2024 · New players come intto monocrystalline silicon rods/wafers links. In 2023, the production capacity of monocrystalline silicon rods will increase by

Get Started

''Greener'' solar wafer production coming to the United States

Feb 13, 2024 · "Silicon wafers are critical materials for the energy transition, and Jonathan''s leadership will be key as we embark on establishing gigawatt-scale wafer manufacturing in the

Get Started

How many homes can 1 gigawatt power?

How many homes can 1 gigawatt power? A GWh is one million kilowatt hours of electricity e enough to power a third of the UKÛs chemical industry for an hour, or around one million

Get Started

Gigawatt vs. Megawatt — What''s the Difference?

Mar 30, 2024 · A gigawatt (GW) is a unit of power equal to one billion watts, while a megawatt (MW) is equal to one million watts, showcasing the scale of

Get Started

Evolving Semiconductor Wafer Technology | TechWeb

Jan 16, 2025 · Currently, 450 mm wafers are in test production, and efforts toward practical use are accelerating. There have also been important developments in semiconductor wafer

Get Started

Influence of Material Composition and Wafer Thickness on

Dec 8, 2024 · Assessing modern silicon solar cells radiation hardness is crucial with the increasing space power demand. The influence of material composition on gallium-doped

Get Started

Solar Cell Production: from silicon wafer to cell

Aug 17, 2023 · This article explains in detail the production process from sliced silicon wafer disks to the final ready-to-assemble solar cell.

Get Started

What Is a Silicon Wafer for Solar Cells?

Most PV modules — like solar panels and shingles — contain at least several and up to hundreds of wafer-based crystalline silicon solar cells. How Does a Wafer-Based Solar Cell Function?

Get Started

Chinese Solar Giants Win Approval for New Wafer Plants in

Jan 13, 2025 · The solar industry is experiencing a significant surge in demand, leading to a tightening of the global silicon wafer supply. In response, Chinese solar giants Jinko Solar and

Get Started

How Are Large Silicon Wafers Improving Chip Performance?

Apr 23, 2025 · One critical advancement helping to achieve superior chip functionality is the use of large silicon wafers. The shift toward larger wafer sizes is more than a manufacturing

Get Started

How Many Solar Panels To Produce A Gigawatt?

Oct 31, 2024 · (August 2025) Solar power is a renewable energy source that is becoming increasingly popular due to its environmental and financial benefits.

Get Started

The solar cell wafering process

May 21, 2024 · In this paper we focus on the wafering process, as it has a comparatively large cost contribution of about 22% in the silicon solar cell manufacturing value chain [1]. Fig. 1

Get Started

6 FAQs about [How many silicon wafers are there in one gigawatt of solar energy]

Are monocrystalline silicon wafers a good choice for solar panels?

Monocrystalline silicon wafers show excellent performance, with efficiencies reaching up to 22%. There is a continuous effort to reach the highest efficiency possible for solar cells, aiming close to 32%. The balance of efficiency, energy production, and affordability is key for sustainable solar panel production.

How big is China's silicon wafer production capacity?

From the perspective of production layout, the silicon wafer production capacity of enterprises located in mainland China will be about 953.6GW by the end of 2023, accounting for 97.9% of the world, occupying an absolute leading position

What is a solar wafer?

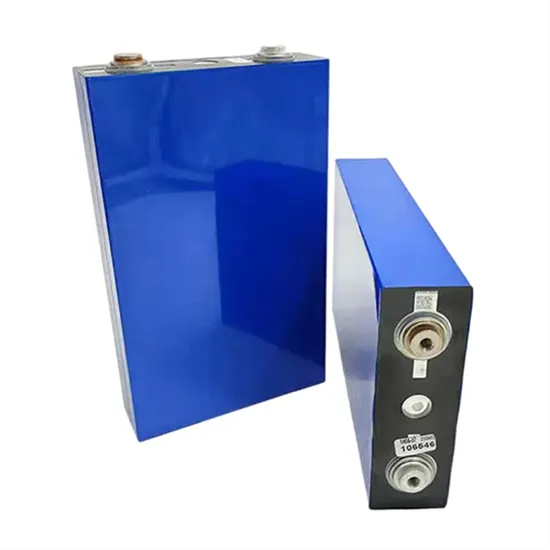

Solar wafers are crucial for this clean energy option. They are made of monocrystalline or polycrystalline silicon. This makes up 95% of today’s solar panel market. Monocrystalline silicon is top-notch, with efficiencies between 18% and 22%. This is remarkable since the highest efficiency for silicon solar cells is around 32%.

How big is a silicon wafer?

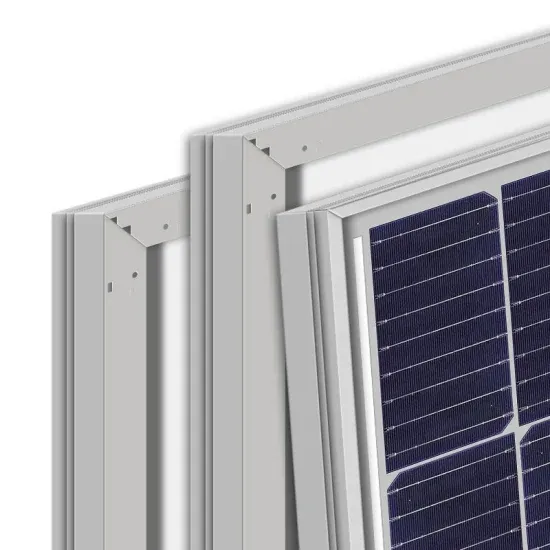

Wafers as large as 210mm 2 (M12) are increasingly used in PV cells — a 35% increase in diameter from the original M0. Much of the cost of manufacturing solar panels comes from the silicon wafer production process.

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

Related Articles

-

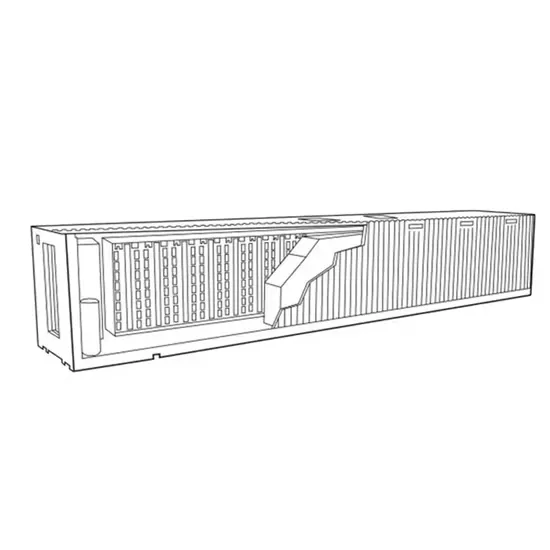

How to place solar energy in containers

How to place solar energy in containers

-

Can silicon solar panels store energy

Can silicon solar panels store energy

-

How much electricity does 10 watts of solar energy generate

How much electricity does 10 watts of solar energy generate

-

How many watts does a 12v monocrystalline silicon solar panel have

How many watts does a 12v monocrystalline silicon solar panel have

-

How do solar panels charge energy storage cabinet sites

How do solar panels charge energy storage cabinet sites

-

How much does 93 kilowatts of solar energy cost

How much does 93 kilowatts of solar energy cost

-

How many watts of solar energy is 360w

How many watts of solar energy is 360w

-

How much solar energy is needed for a 1800w inverter

How much solar energy is needed for a 1800w inverter

-

How many kilowatt-hours of electricity does 60 kilowatts of solar energy generate in a day

How many kilowatt-hours of electricity does 60 kilowatts of solar energy generate in a day

-

How to use solar energy smart outdoor energy

How to use solar energy smart outdoor energy

Commercial & Industrial Solar Storage Market Growth

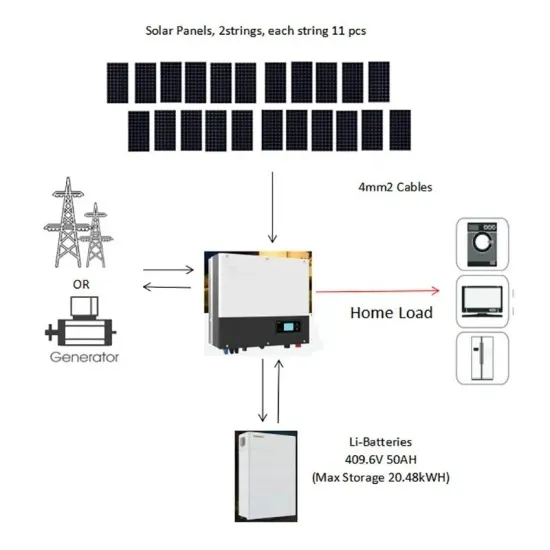

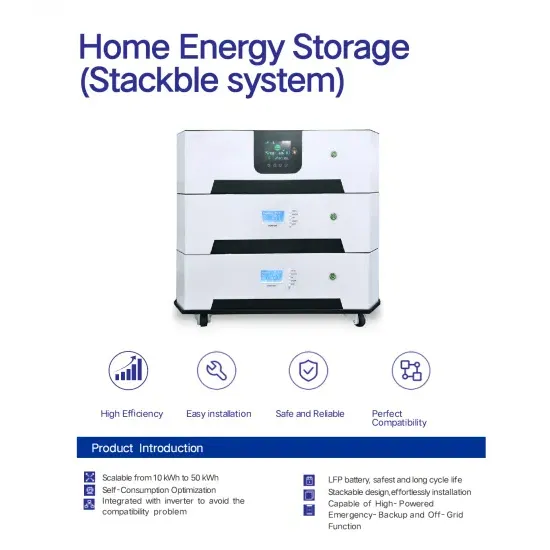

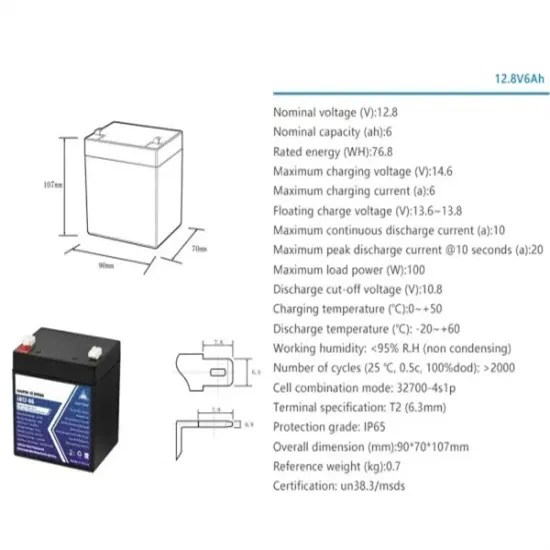

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.