Global Battery Structural Parts Market 2025 by Company,

Jan 1, 2025 · According to our latest research, the global Battery Structural Parts market size will reach USD 10198 million in 2031, growing at a CAGR of 16.4% over the analysis period.

Get Started

China leading cylindrical battery safety structural parts, lithium

Jan 15, 2024 · CZZR is a long-term leading domestic R&D, manufacturing and sales company of cylindrical lithium battery precision safety structural parts. Its main products include power type

Get Started

Lithium Battery Precision Structural Parts Market Share

The global Lithium Battery Precision Structural Parts market was valued at US$ million in 2022 and is projected to reach US$ million by 2029, at a CAGR of % during the forecast period. The

Get Started

Structural batteries: Advances, challenges and perspectives

Jan 1, 2023 · The battery pack acts as a body structure, that links the front and rear underbody parts of the EV due to its improved mechanical properties by implementing 4680-type

Get Started

Unlocking the Future of Lithium Battery Precision Structural Parts

Mar 28, 2025 · The market is segmented by application (cylindrical and square lithium-ion batteries) and type (cylindrical and square structural parts). This segmentation provides

Get Started

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · This research proposes a novel experimental methodology and a theoretical model for evaluating the mechanical performance of cylindrical lithium-ion batteries under

Get Started

Battery Structural Parts Market Outlook

Report Overview Precision structural parts of power lithium battery include shell/cover, etc. Li-ion battery consists of positive electrode material, negative electrode material, diaphragm,

Get Started

Portable Lithium Battery Precision Structural Parts Market: A

Jul 20, 2025 · Portable Lithium Battery Precision Structural Parts Market Revenue was valued at USD output current value here in 2024 and is estimated to reach USD output forecast value

Get Started

Lithium Battery Precision Structural Parts Market Report

Jul 20, 2025 · Lithium Battery Precision Structural Parts Market size was valued at USD output current value herein 2024 and is forecasted to grow at a CAGR of output cagr value here%

Get Started

Design, Properties, and Manufacturing of Cylindrical Li-Ion

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design

Get Started

About Shenzhen Kedali

3 days ago · About Shenzhen Kedali Industry Co., Ltd Kedali was founded in 1996 and was listed on the SME Board of the Shenzhen Stock Exchange in March 2017 (stock code: 002850), with

Get Started

Hong Kong Lithium Battery Precision Structural Parts Market

Jul 27, 2025 · As the global ecosystem becomes increasingly reliant on sustainable energy storage, Hong Kong’s market is poised for substantial growth, bolstered by technological

Get Started

科达利·关于我们

Dec 5, 2024 · The Chinese company specializes in the development and production of precision components for lithium-ion batteries and structural parts for battery components. KEDALI''s

Get Started

Global Lithium Battery Precision Structural Parts Market

Feb 5, 2024 · Lithium battery precision structural components refer to components used in the manufacturing of lithium battery components that have precise structures and critical functions.

Get Started

China''s Zhongrui to Form Battery Parts Joint

Jun 26, 2024 · Zhongrui is one of China''s leading suppliers of precision structural components for cylindrical lithium batteries, mainly cap assemblies, which are

Get Started

EV Lithium Battery Structural Parts Market Analysis Report

Top Key Companies for EV Lithium Battery Structural Parts Market: Kedali, Sangsin EDP, FUJI Spring, Wuxi Jinyang New Material, Dongguan ALI System, Ningbo Zhenyu Technology,

Get Started

Global Lithium Battery Precision Structural Parts Market

Lithium battery precision structural components refer to components used in the manufacturing of lithium battery components that have precise structures and critical functions. These structural

Get Started

A Detailed Comparison Of BYD Prismatic Cell, pouch cell and cylindrical

Based on the packaging form, lithium batteries can be divided into three forms: square, cylindrical and soft-pack. The packaging form refers to the packaging structure of a single lithium battery.

Get Started

Precision Metal Stamping Solutions for Batteries

2 days ago · We design and manufacture precision-stamped component solutions for the lithium-ion battery market. We offer prismatic and cylindrical structural

Get Started

Analyze the Key Points of EV Battery Top Plate

Feb 20, 2024 · Structural Parts: Key Materials for EV Power Batteries Power battery precision structural parts include EV battery top plate covers,

Get Started

China leading cylindrical battery safety structural parts, lithium

Jan 15, 2024 · The expansion project of power lithium battery precision safety structural parts caps is planned to use the production technology independently developed by the company to

Get Started

Portable Lithium Battery Precision Structural Parts Market

Portable Lithium Battery Precision Structural Parts market research report for 2023-2030. Gain valuable insights into industry trends, growth prospects, market share, size and market

Get Started

Structural analysis and experimental characterization of cylindrical

Dec 20, 2014 · We report on modeling mechanical response of cylindrical lithium-ion battery cells that are commonly used in automotive applications when subjected to impact testing. The

Get Started

Precision Metal Stamping Solutions for Batteries & More

2 days ago · We design and manufacture precision-stamped component solutions for the lithium-ion battery market. We offer prismatic and cylindrical structural components and lid assemblies

Get Started

Global Lithium Battery Precision Structural Parts Market 2023

The Global Info Research report includes an overview of the development of the Lithium Battery Precision Structural Parts industry chain, the market status of Cylindrical Lithium-Ion Battery

Get Started

Lithium Battery Precision Structural Parts

Lithium battery precision structural components refer to components used in the manufacturing of lithium battery components that have precise structures and critical functions. These structural

Get Started

Lithium battery precision structural parts company

The Portable Lithium Battery Precision Structural Parts market size, estimations, and forecasts are provided in terms of output/shipments (K Units) and revenue ($ millions), considering 2023

Get Started

The market size of lithium battery structural

Apr 23, 2023 · In 2023, cylindrical structural parts are expected to usher in development opportunities. The 4680 battery is expected to enter large-scale

Get Started

The Detailed Comparison Of BYD Prismatic Cell,

Jun 20, 2025 · Different packaging forms correspond to different process steps and also correspond to different forms of battery precision structural parts. At

Get Started

Lithium Battery Precision Structural Parts

The global Lithium Battery Precision Structural Parts market size is expected to reach US$ million by 2029, growing at a CAGR of % from 2023 to 2029. The market is mainly driven by the

Get Started

Round Lithium Battery Structural Parts Market

EVs rely heavily on cylindrical lithium-ion batteries due to their high energy density and thermal stability. For example, Tesla''s 4680 battery cells, designed for improved efficiency and

Get Started

6 FAQs about [Cylindrical lithium battery precision structural parts]

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

How do you model a cylindrical lithium-ion battery?

For the modeling of cylindrical lithium-ion batteries, detailed structural models including cathode material, cathode material, diaphragms, and shells can more accurately react to battery deformation and faults, and determine the failure position, but usually require significant computational costs and the model is particularly complex.

What is a cylinder Li-ion battery?

Cylindrical Li-ion battery cells consist of (i) a jelly roll, a wound composite consisting of a cathode, an anode, and two separators, and (ii) a cell housing consisting of a can and a cap . Current and heat transport between the jelly roll and the cell housing is traditionally conducted by contacting elements called tabs .

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

Does the 18650 cylindrical lithium-ion battery have a quasi-static compression test?

4. Conclusion In this paper, the 18650 cylindrical lithium-ion battery and its jellyroll quasi-static compression test, and establishes an optimization model based on the experimental results.

Related Articles

-

Cylindrical lithium battery expansion

Cylindrical lithium battery expansion

-

26500 cylindrical lithium battery

26500 cylindrical lithium battery

-

Cylindrical lithium battery automatic charging equipment

Cylindrical lithium battery automatic charging equipment

-

Croatia cylindrical lithium battery customization

Croatia cylindrical lithium battery customization

-

Lithium Cylindrical Battery

Lithium Cylindrical Battery

-

Huawei cylindrical lithium battery procurement channels

Huawei cylindrical lithium battery procurement channels

-

Azerbaijan cylindrical lithium battery customization

Azerbaijan cylindrical lithium battery customization

-

Is the cylindrical battery a lithium iron phosphate battery

Is the cylindrical battery a lithium iron phosphate battery

-

4V 2600mh cylindrical lithium battery price

4V 2600mh cylindrical lithium battery price

-

Roman cylindrical lithium battery price

Roman cylindrical lithium battery price

Commercial & Industrial Solar Storage Market Growth

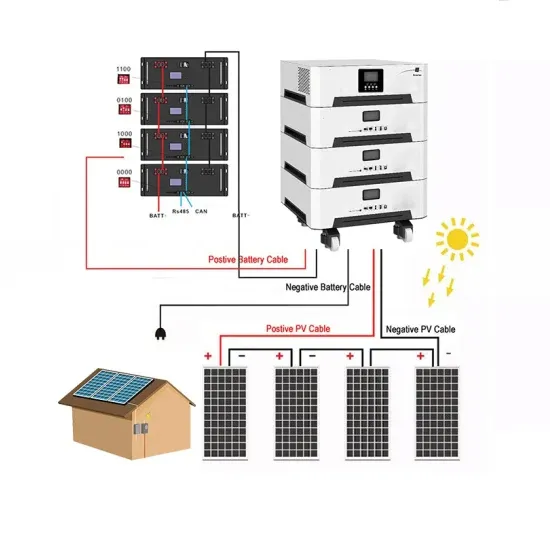

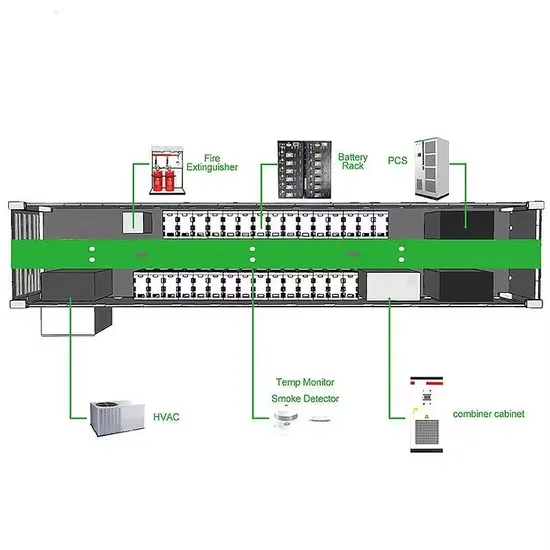

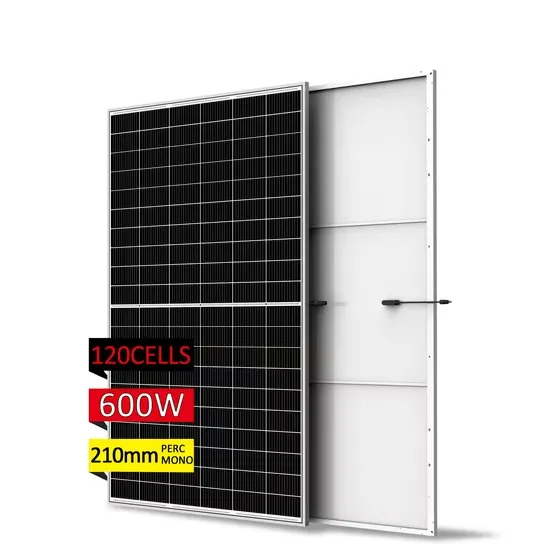

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.