VFD Switching Frequency

Oct 17, 2017 · Switching Frequency – Effect on high-frequency outputs As the motor output frequency increases, the impact of the VFD switching frequency

Get Started

How Does a Frequency Inverter Work?

Dec 13, 2023 · Frequency inverters can be used in home appliances. Among the home appliances that use a frequency inverter are not only motors (e.g., air

Get Started

Changing the frequency of an AC supply

Oct 26, 2013 · I am using an AC Power supply, and the frequency of the wall plugs is around 50hz. Is there a way to increase this frequency keeping

Get Started

How does an increase in operating frequency result in

Dec 1, 2013 · I was reading about inverters in a textbook where the author says that The size and cost of the circuit can be reduced to some extent if the operating frequency is increased but

Get Started

Frequency inverters, Engineering and Commissioning

Dec 8, 2020 · Frequency inverters have an efficiency of > 95 %. With process optimization, the use of frequency inverters can provide energy savings which greatly offsets the losses of the

Get Started

analysis

Jan 7, 2015 · Im using an inverter to convert Dc into Ac from battery. I want to control the frequency of the alternating current ie., increase and decrease

Get Started

What is a frequency inverter?

Jan 15, 2024 · A frequency inverter changes output voltage frequency and magnitude to vary the speed, power, and torque of a connected induction

Get Started

Frequency inverters | Explanation, function

Frequency inverters are electronic devices that create an AC voltage with variable frequency from an AC voltage with fixed frequency (e.g. 50 Hz). They are

Get Started

How Inverters Work

Dec 15, 2017 · How do Inverters work? In this article we''ll be learning how inverters work, starting from the very basics. We''ll cover Pulse Width

Get Started

Mastering Inverter Switching Frequencies: A

Apr 25, 2024 · The switching frequency of inverters in electric motor applications is critically controlled to optimize performance, efficiency, and minimize noise

Get Started

Power Frequency Inverter vs. High Frequency

May 15, 2024 · To sum up, variable frequency inverters and high frequency inverters each have their own advantages and disadvantages and are suitable

Get Started

Guide to Frequency Inverters: Optimizing Motor

I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in modern motor control systems. These

Get Started

What is a Frequency Inverter? A Complete Guide to How It

4 days ago · A frequency inverter is an electronic device that converts the fixed frequency and fixed voltage from your electrical supply (e.g.,50Hz or 60Hz,240V or 480V)into a variable

Get Started

MEZ Electric Motors

Jun 23, 2024 · Please note that the motor performance at speeds under 5Hz depends on the frequency inverter more than on the motor. If you operate the motor at speeds greater than the

Get Started

Frequency inverter

3 days ago · A frequency inverter enables the conversion of the electrical variable ''current''. The text contains information about setup and different types of inverters.

Get Started

Frequency Inverter

5 days ago · Frequency Inverters, or Variable Frequency Drives, are indispensable tools for industrial automation, offering unmatched flexibility,

Get Started

The Power Factor of Frequency Inverter

Increases voltage within the AC inductor, reducing current and stress throughout the entire chain of frequency inverter power components while minimizing

Get Started

Power Inverter vs. Frequency Inverter

Jan 20, 2021 · A frequency inverter, also named VFD, is a kind of power control equipment adopting frequency conversion technology and microelectronics

Get Started

The highest frequency and basic frequency of

May 14, 2024 · The maximum frequency is the maximum frequency that the inverter allows to output, expressed by fmax. Its specific meaning varies

Get Started

The Ring Oscillator [A Circuit for All Seasons]

Dec 11, 2019 · The inverter-based ring shown in Figure 2 merits three remarks. First, since the delay of an inverter falls as the supply voltage VDD increases, the oscillation frequency f is

Get Started

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · By altering the frequency, the inverter can slow down or speed up the motor, offering exceptional flexibility for processes requiring variable

Get Started

A Complete Guide to Inverters/Variable

Jan 1, 2025 · There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical

Get Started

Main Parameters of Frequency Inverter

Apr 19, 2024 · The frequency inverter controls the power control equipment of the AC motor by changing the frequency of the motor''s operating power supply. It

Get Started

Frequency Inverter

5 days ago · A Frequency Inverter is an electronic device used to control the speed of an AC motor by varying the motor''s input frequency and voltage. By

Get Started

Research on the influence of switching frequency on the

Nov 1, 2022 · (1) The five types of inverters all show that with the increase of SCR, the stability of CCI decreases continuously, so this law is not affected by the switching frequency.

Get Started

Frequency inverters | Explanation, function & design

Frequency inverters increase system efficiency If, for example, an asynchronous motor is controlled by a frequency inverter, regulating the speed range also reduces the energy

Get Started

Why should we increase invert frequency

Oct 12, 2023 · The most effect of high invert frequency: With the increase of the invert switching frequency, the volume and weight of the inverter are also reduced, and the power density is

Get Started

Mastering These 16 Frequency Inverter

Jan 23, 2025 · Frequency inverters have numerous setting parameters, each with a specific range of selection. It''s common to encounter issues where incorrect

Get Started

Frequency Inverter Basic: Introduction, Functions

Dec 11, 2023 · Frequency inverter relies on the internal IGBT to adjust the voltage and frequency of the output power supply, according to the actual needs of the

Get Started

What is a Frequency Inverter and Why is it So Widely Used?

Apr 27, 2025 · Frequency inverters enable smooth motor starting and stopping, reducing mechanical stress and extending equipment lifespan. They also offer precise speed control,

Get Started

How the Switching Frequency Affects the Performance

Apr 16, 2024 · 6 Conclusion This application note analyzes the effect of switching frequency on the performance of buck converter. The higher the switching frequency, the smaller inductor

Get Started

6 FAQs about [Inverter increases frequency]

What is a frequency inverter?

Frequency inverters are electronic devices that create an AC voltage with variable frequency from an AC voltage with fixed frequency (e.g. 50 Hz). They are usually installed between the supply network and an electric motor so that its speed can be controlled steplessly and precisely and so that its energy consumption can be optimised.

Why do Inverters change frequency?

By altering the frequency, the inverter can slow down or speed up the motor, offering exceptional flexibility for processes requiring variable speeds. This ability not only enhances energy efficiency but also minimizes the wear on mechanical components, resulting in longer motor life and fewer maintenance issues. III.

How do frequency inverters affect motor performance?

A frequency inverter’s primary function is to manage motor performance by adjusting the electrical supply, but the way it does this can vary depending on the method of control used and the motor's specific demands. Here's a breakdown of how frequency inverters influence motor performance:

How does a frequency inverter change the speed of a motor?

Speed Regulation Function: Frequency inverters can change the speed of the motor by adjusting the frequency of the power supply. This is very important for applications that require flexible speed control, such as in industrial production, where different production processes may require different speeds.

Why do we need frequency inverters?

By realizing variable speed control of motors, frequency inverters play a key role in improving production efficiency, saving energy reducing consumption, and reducing equipment loss.

Can a frequency inverter run a motor above 50Hz?

While most motors are designed to operate at a frequency of 50Hz, there are many situations where higher speeds are necessary. Frequency inverters provide the flexibility to run motors above 50Hz, allowing for increased operational speeds and improved performance in certain applications.

Related Articles

-

How much does a high frequency inverter output

How much does a high frequency inverter output

-

Inverter high frequency control

Inverter high frequency control

-

Energy storage inverter grid frequency regulation

Energy storage inverter grid frequency regulation

-

Sucre Electric Industrial Frequency Inverter Price

Sucre Electric Industrial Frequency Inverter Price

-

Assembly 3kw industrial frequency inverter

Assembly 3kw industrial frequency inverter

-

Rv outdoor use fast frequency sine inverter

Rv outdoor use fast frequency sine inverter

-

Huawei industrial frequency inverter 20kw

Huawei industrial frequency inverter 20kw

-

The difference between inverter high frequency and industrial frequency

The difference between inverter high frequency and industrial frequency

-

50 Hz high frequency inverter

50 Hz high frequency inverter

-

Asia EK High Frequency Inverter

Asia EK High Frequency Inverter

Commercial & Industrial Solar Storage Market Growth

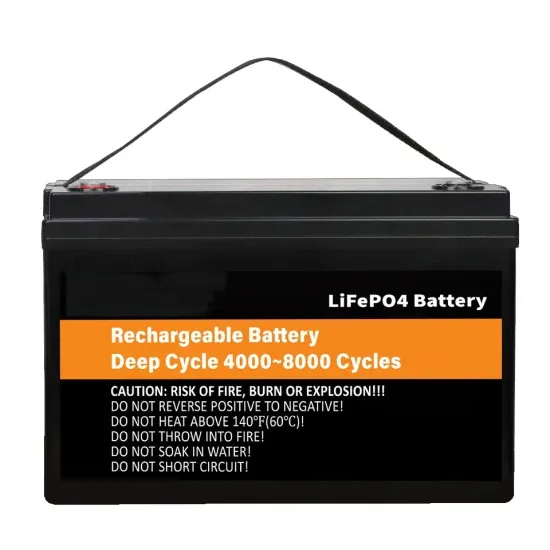

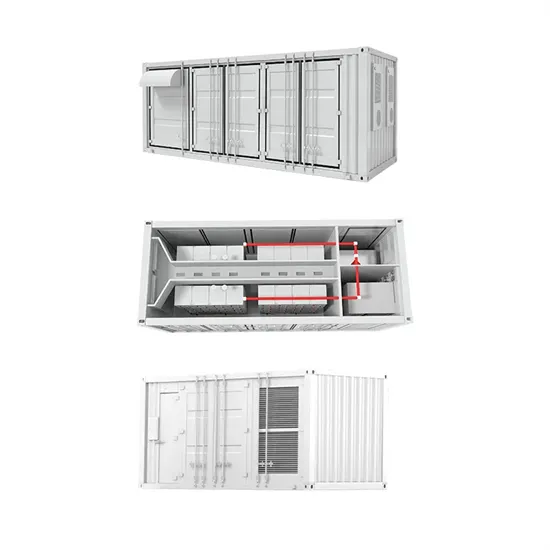

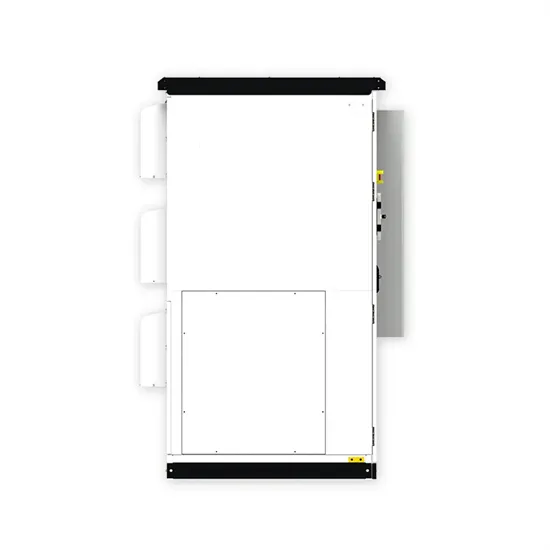

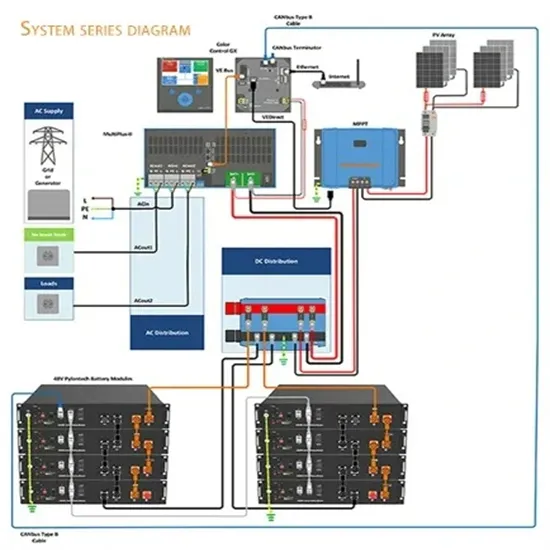

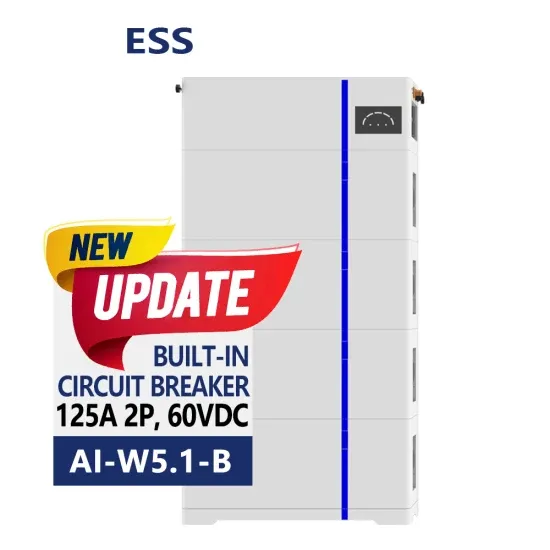

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

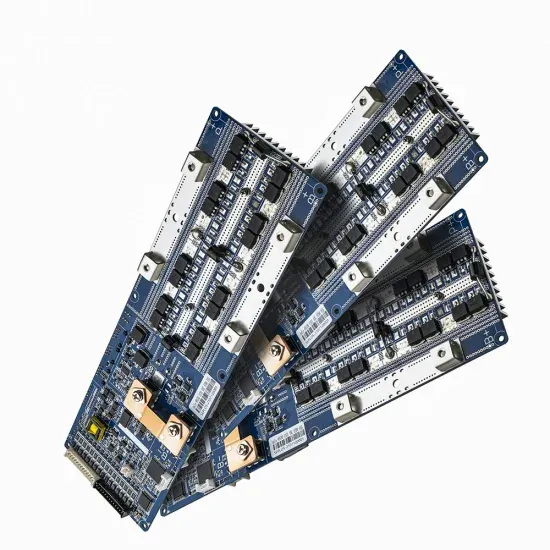

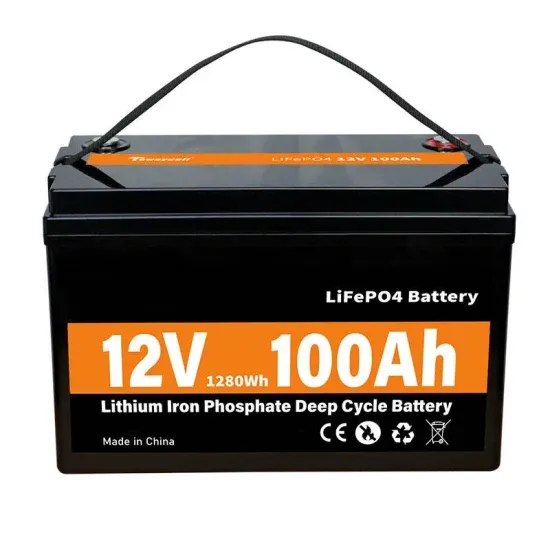

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.