Lithium Battery Cell Quality | NAZ Solar Electric

Feb 9, 2024 · Explore the critical role of cell quality in lithium batteries for Energy Storage Systems (ESS). Delve into our comprehensive guide on the

Get Started

Challenges and opportunities for high-quality battery

Jan 12, 2025 · Here we highlight both the challenges and opportunities to enable battery quality at scale. We first describe the interplay between various battery failure modes and their

Get Started

How to Find Bad Cells in a Battery Pack? A Step-by-Step Guide

Jan 8, 2025 · Learn how to find bad cells in a battery pack with easy step-by-step methods, from visual checks to voltage tests, and get your devices back to peak performance.

Get Started

Quality Management for Battery Production: A Quality Gate

Jan 1, 2016 · In order to reduce costs and improve the quality of lithium-ion batteries, a comprehensive quality management concept is proposed in this paper. Goal is the definition of

Get Started

Judging the quality of lithium battery pack

A lithium-ion battery pack, timing measurement technology, applied in the direction of measuring current/voltage, measuring electricity, measuring electrical variables, etc., can solve the

Get Started

Lithium Battery Cell Quality | NAZ Solar Electric

Feb 9, 2024 · Lithium Battery Cell Technology The use of energy storage systems (ESS) in residential and commercial settings has been rapidly evolving with

Get Started

The best lithium cells for industry

Jan 23, 2020 · Cylindrical cells Cylindrical cells for lithium batteries are very similar to the batteries in our remote controls at hom e. The most common format is the 18650 cell (18mm diameter,

Get Started

How to judge the consistency of lithium battery packs cells

Feb 25, 2021 · To measure the capacity internal resistance and discharge platform of a single battery, it also depends on the process level of lithium battery assembly and the battery

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Started

Empowering lithium-ion battery manufacturing with big

Dec 15, 2024 · Abstract With the rapid development of new energy vehicles and electrochemical energy storage, the demand for lithium-ion batteries has witnessed a significant surge. The

Get Started

Judging the quality of rechargeable battery pack

Qian et al. evaluated the consistency of grouped lithium-ion batteries based on characteristic peaks of incremental capacity curves. This method can quickly describe the consistency issue

Get Started

Quality Management for Battery Production: A

Dec 31, 2016 · In order to reduce costs and improve the quality of lithium-ion batteries, a comprehensive quality management concept is proposed in this

Get Started

Ensuring the Quality of Lithium Ion Battery

Jul 11, 2024 · Lithium-ion (Li-ion) batteries power many of our daily devices. However, manufacturing them requires scarce base metals and has supply

Get Started

Thermal runaway front propagation characteristics, modeling and judging

Sep 1, 2024 · Large-format prismatic Li-ion batteries (LIBs) are prominent energy storage devices in electric transportation applications. However, large-format LIB induces severe thermal

Get Started

Know your Lithium-ion Cells, Cell Specifications

Feb 4, 2021 · The article covers: Lithium-ion Cell Specifications and data sheets Important Terms related to cell/battery performance and their description

Get Started

The Complete Guide To Choose Lithium Battery

Lithium-ion battery cells have a number of specifications that are important to consider when selecting a battery for a particular application. Here are some

Get Started

Early Quality Classification and Prediction of Battery Cycle

Jun 1, 2022 · An accurate determination of the product quality is one of the key challenges in lithium-ion battery (LIB) production. Since LIBs are complex, electrochemical systems,

Get Started

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Get Started

Battery Cell Testing for Enhancing the Pack Lifespan

Jul 4, 2025 · To tackle this issue, ZwickRoell and MBTS have developed an battery cell test bench that enables precise pressure monitoring, enhancing battery efficiency, longevity, and

Get Started

How to Identify High-Quality Lithium Battery Cells?

Jan 15, 2025 · High-quality lithium battery cells stand out for their performance, reliability, and safety. Learn what sets them apart in materials, manufacturing, and testing

Get Started

How to Identify High-Quality Lithium Battery Cells?

Jan 15, 2025 · High-quality lithium battery cells can last between 500 to 3000 charge cycles, depending on the chemistry and usage conditions. For example, LFP batteries tend to have

Get Started

Improving Performance and Quality of Lithium

Mar 26, 2025 · FTIR, Raman Microscopy, XRF, XPS and ICP are essential techniques for compositional analysis of raw materials and to study changes

Get Started

Battery Cells, Modules, and Packs: Key Differences Explained

Apr 18, 2025 · Learn the differences between battery cells, modules, and packs, and how they work together to power applications efficiently.

Get Started

Non-destructive characterization techniques for battery

Jul 9, 2024 · This Review examines the latest advances in non-destructive operando characterization techniques and their potential to improve our comprehension of degradation

Get Started

5 Simple Ways To Judge The Quality Of Lithium

Uncover the secrets of evaluating the quality of lithium batteries with our comprehensive guide! Learn about the 5 key standards for evaluating the

Get Started

Lithium-ion cells – A grade vs B grade

Oct 19, 2021 · A few OEMs and battery pack suppliers have experienced issues with using B grade cells because their batteries could not perform up to

Get Started

Quality Assurance for Lithium

Jan 18, 2024 · s - speed, accuracy, robustness and operational costs. Combined with the power of intelligent algorithms, machine-learning and digital twin modelling, the impedance data of

Get Started

Quality Control and Management Systems for Lithium-Ion Battery

Apr 23, 2025 · In response to increasing environmental concerns and the transition toward electromobility, lithium-ion batteries (LIBs) have become the dominant energy source for

Get Started

Understanding Global Lithium Battery Standards

Feb 11, 2025 · They have specific standards that ensure the safety of lithium-ion cells in consumer electronics (UL 1642), apply to battery pack durability (UL

Get Started

Quality Assurance and Sustainability in Lithium

Jan 5, 2023 · This article explores how real-time, in-line measurement systems can help manufacturers to maintain the quality and safety of their lithium-ion

Get Started

Quality Assurance for Lithium

Jan 18, 2024 · Executive Summary Lithium-ion batteries are developing into a widely used technology in the field of electromobility, defense and stationary energy storage owing to their

Get Started

Analysis of Lithium Battery Cell Grades: A, B, and C

Jan 28, 2024 · As a crucial energy source for modern electronic devices, the performance and quality of lithium batteries depend directly on the quality of

Get Started

Evaluating the Manufacturing Quality of Lithium Ion Pouch Batteries

Apr 19, 2022 · Lithium-ion batteries must undergo a series of quality control tests before being approved for sale. In this study, quality control tests were carried out on two types of lithium

Get Started

Best practices in lithium battery cell preparation and evaluation

Sep 9, 2022 · Coin and pouch cells are typically fabricated to assess the performance of new materials and components for lithium batteries. Here, parameters related to cell fabrication that

Get Started

EV Lithium Battery PACK Design Process from

Mar 18, 2025 · EV Lithium Battery PACK Design Process: A Comprehensive Guide The design of Electric Vehicle (EV) lithium battery packs ⇱ is a complex

Get Started

6 FAQs about [Judging the quality of lithium battery pack cells]

How to evaluate a lithium-ion battery quality?

Discrepancies existed for the cathode material. For cell B, the NMC material specified by the battery manufacturer turned out to be LCO. From this analysis it can be concluded that lithium-ion battery quality evaluation should incorporate electrochemical performance tests and assessments of assembly precision and material composition.

Do lithium-ion batteries need a quality control test?

Published on behalf of The Electrochemical Society by IOP Publishing Limited Journal of The Electrochemical Society, Volume 169, Number 4 Citation Lingxi Kong et al 2022 J. Electrochem. Soc.169 040541DOI 10.1149/1945-7111/ac6539 Lithium-ion batteries must undergo a series of quality control tests before being approved for sale.

Why do we need improved lithium batteries?

Improved lithium batteries are in high demand for consumer electronics and electric vehicles. In order to accurately evaluate new materials and components, battery cells need to be fabricated and tested in a controlled environment.

What are lithium-ion batteries used for?

The use of lithium-ion batteries (LIBs) increases across applications of automobiles, stationary energy storage, consumer electronics, medical devices, aviation, and automated infrastructure, 1 – 6 assuring the battery quality becomes increasingly essential.

What is the production chain of lithium ion batteries?

Production chain for lithium-ion batteries Lithium-ion cells are galvanic elements that convert electrical energy into chemical energy and vice versa . Hence, they are able to store and release large amounts of energy, e.g. electricity generated by solar or wind energy used to power an electric vehicle.

Are quality management tools limiting the production chain of lithium-ion cells?

It has been shown that current quality management tools easily face their limits when applied to the production chain of lithium-ion cells due to its complexity and the need for real time processing of collected data.

Related Articles

-

Lithium battery pack quality inspection items

Lithium battery pack quality inspection items

-

Lithium battery pack small cells

Lithium battery pack small cells

-

Lithium battery pack DC384

Lithium battery pack DC384

-

Eastern Europe 14500 lithium battery pack wholesale

Eastern Europe 14500 lithium battery pack wholesale

-

High temperature lithium battery pack

High temperature lithium battery pack

-

48v100ah lithium iron phosphate battery pack

48v100ah lithium iron phosphate battery pack

-

8 lithium battery pack

8 lithium battery pack

-

Use of Portonovo lithium battery pack

Use of Portonovo lithium battery pack

-

Lithium battery pack charging overvoltage charging

Lithium battery pack charging overvoltage charging

-

How many mAh is the lithium battery pack

How many mAh is the lithium battery pack

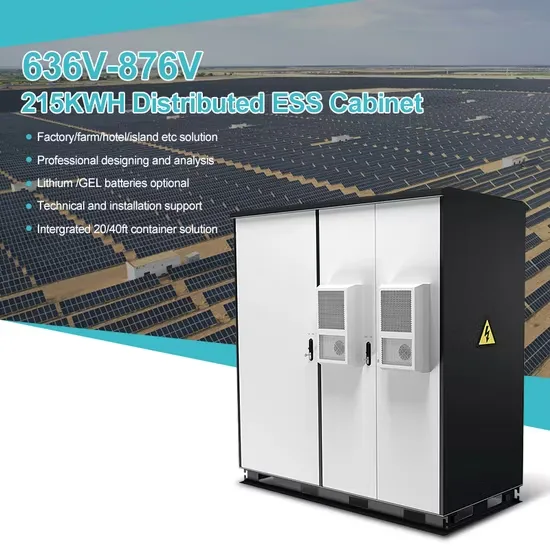

Commercial & Industrial Solar Storage Market Growth

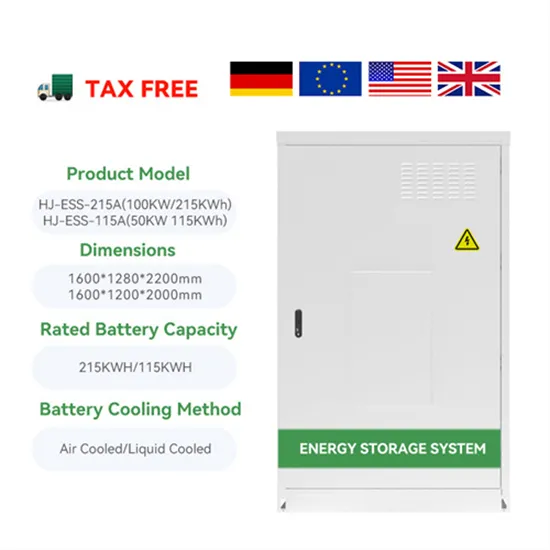

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

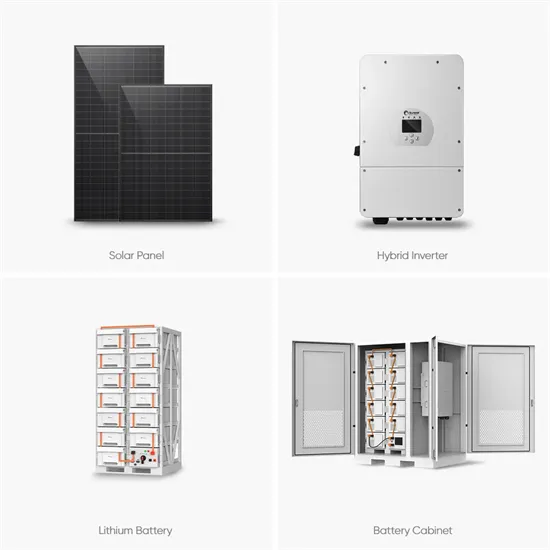

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.