Understanding Lithium Battery Testing

Sep 19, 2024 · Learn how lithium battery testing standards ensure safety, reliability, and compliance. Discover key tests like capacity, thermal, and cycle

Get Started

Lithium Ion Battery (LIB) for X-ray Inspection

Jun 12, 2025 · X-ray inspection systems are used to inspect the quality of lithium-ion batteries. As internal defects of the lithium-ion batteries could be caused

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Get Started

Lithium battery pack quality inspection items

This article will introduce several common lithium battery pack quality inspection methods, including visual inspection, electrical performance test, safety assessment, etc., to

Get Started

Incoming Inspection of Lithium‐Ion Batteries Based on

Jul 9, 2024 · In this work, the use of a multi-cell testing procedure involving differential voltage analysis, incremental capacity analysis, direct current internal resistance tests, and

Get Started

Lithium Battery Receiving Inspection Checklist

Aug 17, 2025 · thinkSTG internal Lithium Ion Battery inspection and safety checklist for receipt of Lithium Ion Battery products.

Get Started

Inspection in Assembly of Li-ion Battery Packs for EVs

Batteries go through an acceptance inspection before they are put together into modules and packs. This is because things like vibrations during shipping and even the passing of time can

Get Started

3D Machine Vision for Battery Production

Mar 21, 2025 · SICK is a leading provider of industrial automation solutions and applies its experience in battery production in the areas of machine safety, traceability, detection and

Get Started

Battery Inspection

Dec 20, 2022 · X-ray sources suited for battery inspection Due to the wide variety of battery types and inspection needs, various resolutions and voltages are

Get Started

Lithium Ion Battery Quality Control | Lithium-Ion

Quality Assurance When Procuring Lithium Ion Battery Systems,High standard quality management for battery production,JB Battery always offering good

Get Started

Lithium battery quality inspection items include

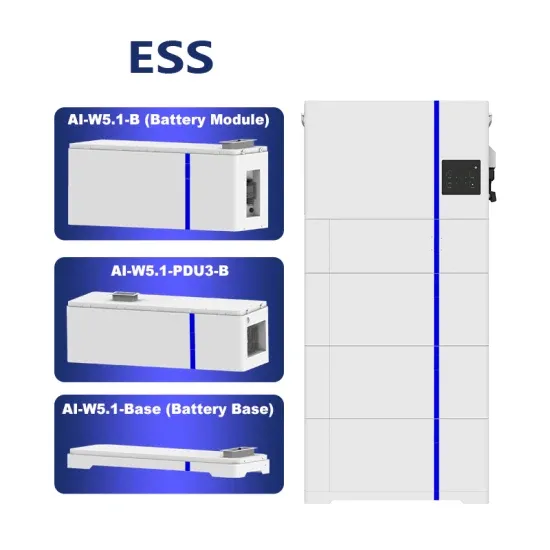

Our range of products is designed to meet the diverse needs of base station energy storage. From high-capacity lithium-ion batteries to advanced energy management systems, each

Get Started

INLINE QUALITY INSPECTION IN BATTERY

2 days ago · Inline quality inspection for battery production: web-based processes (separator, electrode films) and cell production (prismatic, cylindrical, pouch

Get Started

Battery Division Supplier Quality Manual

Sep 25, 2023 · The supplier shall conduct trend management using statistical methods for assurance items determined in the "purchase specification" or etc. (specifically, items

Get Started

Discussion on the Quality Detection Method of Lithium Battery

Mar 15, 2024 · This article will introduce several common lithium battery pack quality inspection methods, including visual inspection, electrical performance test, safety assessment, etc., to

Get Started

Lithium Ion Battery Pack Testing

Aug 18, 2025 · We will examine the challenges of testing Lithium battery packs, uncovering their unique design features and operational traits. We''ll navigate

Get Started

Battery Quality Control: Analytical Techniques

May 16, 2025 · Explore battery quality control techniques used in lithium-ion battery testing, failure analysis, and performance validation across the battery

Get Started

Inline quality inspection battery production

6 days ago · Quality monitoring of the battery production process is essential to ensure an eficient, economical, and sustainable production. Using inline quality inspection systems at

Get Started

Inspecting your primary batteries: what you

Apr 5, 2023 · A continuous discharge isn''t representative of the cells'' behavior under the application''s pulse profile Some developers may be tempted to test

Get Started

Battery Quality at Scale

Apr 20, 2024 · Despite the incredible momentum of lithium-ion batteries in the past five years, three major challenges loom over the industry: These three

Get Started

Lithium battery pack inspection and maintenance video

Quality Li-ion cells are not readily available because a reputable battery manufacturer only sells to certified pack assemblers (See BU-305: Building a Lithium-ion Pack) In addition, quality Li-ion

Get Started

BHCS38534-DE Waygate Battery Inspection White

Global battery demand, critical failure points, and the rise of CT inspection The battery market is in a period of unprecedented growth. Cell phones, toys, consumer electronics, electric

Get Started

Lithium battery pack quality inspection

Batteries | Free Full-Text | High-Potential Test for Quality Control of Separator Defects in Battery Lithium-ion batteries are a key technology for electromobility; thus, quality control in cell

Get Started

Inspection and Analysis Solution for Quality Management of Lithium

Jan 7, 2025 · This article describes a quality management solution and associated technologies for use in the LIB production process with inspection and analysis systems supplied by Hitachi

Get Started

Lithium-ion Battery Production and Testing

Lithium-ion Battery Weld Quality Testing If welds connecting tabs, collectors, and other battery components are insufficient, resistance between components will

Get Started

What are the contents of battery pack inspection

Quality control in lithium-ion battery PACK production: A critical Inspection of raw materials: Raw materials, such as lithium-ion cells, protection circuit boards, and connectors, must be

Get Started

Lithium-ion battery inspection

Aug 8, 2025 · Explore Hamamatsu''s advanced X-ray solutions for lithium-ion battery inspection. Learn how microfocus X-ray sources, flat panel sensors,

Get Started

Focus! The implementation rules for quality supervision and

Jul 9, 2025 · On June 23, 2025, the State Administration for Market Regulation issued an announcement on the implementation rules for quality supervision and random inspection of

Get Started

Quality Management for Battery Production: A Quality Gate

Jan 1, 2016 · High costs and large quality fluctuations during the production of high-energy batteries are considered to be among the main impediments of electric cars to succeed on the

Get Started

Lithium Battery Inspection Std. Antpedia

Nov 11, 2023 · General Administration of Quality Supervision, Inspection and Quarantine of the People''s Republic of China, Lithium Battery Inspection GB 19521.11-2005 Safety code for

Get Started

Factory lithium battery shell inspection items

Ensure product safety with Battery Certification. Discover Tritek''''s expertly crafted lithium-ion battery packs for reliable energy solutions. Standard Scope of application Certification

Get Started

QUALITY CONTROL IN THE PRODUCTION OF

Jul 18, 2024 · QUALITY CONTROL IN THE PRODUCTION OF BATTERY SYSTEMS tandards for safety and reliability. Meticulous attention to measurement, inspection and testing is

Get Started

Lithium Battery Pack Assembly: A

May 6, 2024 · Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations

Get Started

Battery Inspection Checklist

Oct 10, 2024 · This detailed Battery Inspection Checklist ensures battery performance and safety. This checklist, which includes both visual and

Get Started

6 FAQs about [Lithium battery pack quality inspection items]

What are the test items for incoming inspection of lithium-ion battery cells?

Through the tests of the automatic battery sorter and the battery cycler, the main core test items for the incoming inspection of lithium-ion battery cells have been completed. The remaining items are mainly inspected and sampled manually, such as size inspection and appearance inspection.

How is a lithium ion battery inspected?

The remaining items are mainly inspected and sampled manually, such as size inspection and appearance inspection. The size of lithium-ion battery cells is generally measured with a vernier caliper.

What is X-ray inspection for lithium ion batteries?

X-ray inspection for cylindrical lithium-ion batteries X-ray inspection for prismatic/pouch lithium-ion batteries (winding type) X-ray inspection for prismatic/pouch lithium-ion batteries (stacking type) As the causes of LiB failures gradually become clearer, there is a growing demand to inspect more complex structures and find minute defects.

What is a battery incoming inspection?

In this process, the actual capacity of the battery cells can also be tested, and the battery cell incoming inspection standards can be compared to determine whether the capacity and cycle life of the battery cells meet the technical and quality requirements.

Who is a professional battery pack assembly equipment supplier?

As a professional battery pack assembly equipment and battery testing equipment supplier, WinAck can provide mature lithium-ion battery cell incoming inspection solutions.

Why is quality control important for lithium-ion batteries?

As lithium-ion batteries become integral to technological innovation, quality control has emerged as a key discipline in ensuring their safety, reliability, and performance. Battery quality control is not limited to electrical performance; it requires rigorous materials testing to verify purity, detect contamination, and assess degradation.

Related Articles

-

Czech lithium battery pack has good quality

Czech lithium battery pack has good quality

-

Quality inspection of lithium battery energy storage power station

Quality inspection of lithium battery energy storage power station

-

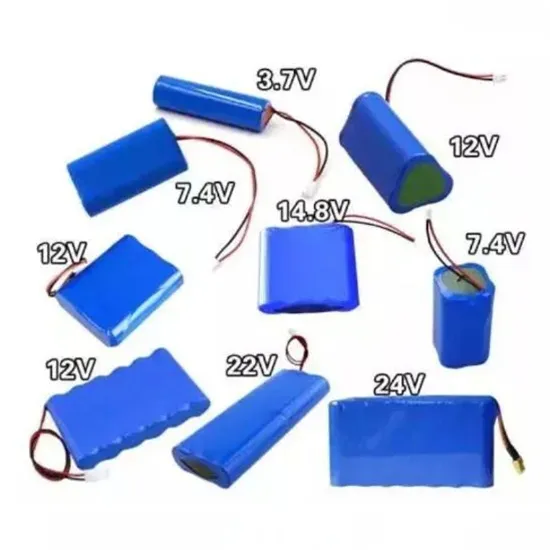

Judging the quality of lithium battery pack cells

Judging the quality of lithium battery pack cells

-

What nickel sheet is used in lithium battery pack

What nickel sheet is used in lithium battery pack

-

How many kilowatt-hours can a 60v125ah lithium battery pack charge

How many kilowatt-hours can a 60v125ah lithium battery pack charge

-

Lithium battery pack small cells

Lithium battery pack small cells

-

Solar lithium battery pack storage and control integrated

Solar lithium battery pack storage and control integrated

-

6v lithium battery pack

6v lithium battery pack

-

Xia 12v lithium battery pack

Xia 12v lithium battery pack

-

Monaco pack lithium battery custom manufacturer

Monaco pack lithium battery custom manufacturer

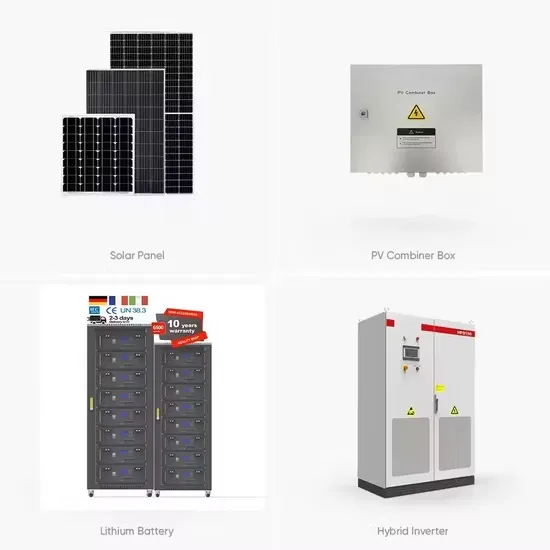

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.