Understanding the Role and Importance of Nickel Strip in Battery

Apr 23, 2024 · Nickel strip is typically made from pure nickel or nickel alloys, such as nickel-copper (NiCu) or nickel-iron (NiFe). These materials are chosen for their high conductivity,

Get Started

Why is nickel strip often used in lithium battery

Jun 6, 2025 · What role does the nickel strip play in a battery? Nickel strips are widely used in lithium battery manufacturing, which is highly consistent with its unique physical and chemical

Get Started

Nickel sheet for lithium battery pack

Jul 15, 2017 · The nickel sheet is used to connected each battery when making the battery pack. Current,there are 4 types connecting sheet used in our products: Type 1: Stainless still sheet

Get Started

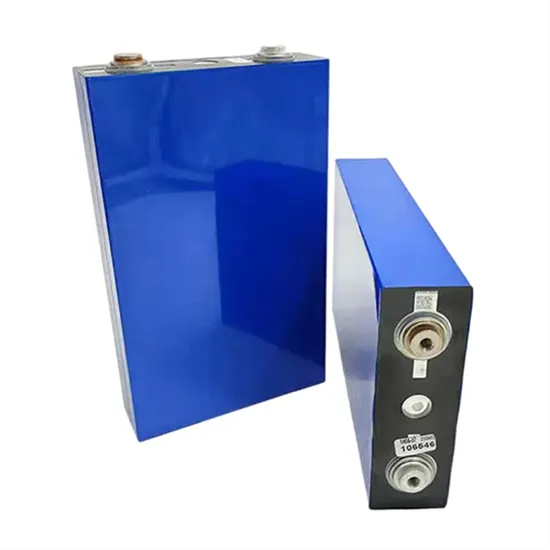

BU-205: Types of Lithium-ion

Dec 8, 2023 · Become familiar with the many different types of lithium-ion batteries: Lithium Cobalt Oxide, Lithium Manganese Oxide, Lithium Iron

Get Started

Electrode Sheets for Li-ion Battery

Aug 19, 2025 · Electrode sheets contribute significantly to determining the overall performance of cells in lithium-ion battery manufacturing. Optimized for use in

Get Started

Battery Spot Welder: Guide for Lithium Battery

May 24, 2024 · Learn how to use a battery spot welder for lithium packs, with tips on equipment, techniques, and ensuring strong, safe welds.

Get Started

Copper strips versus nickel strips on battery packs?

Reference: Samsung 30Q 12Ah pack. Maximum current draw 25 amps. Would this pack built using copper strips, have any significant advantages over the

Get Started

Standard Materials and Components in Battery

Jun 29, 2020 · At Epec we provide battery pack design, creation, and manufacturing work to customers in the medical, aerospace, food service, and

Get Started

Properties of Flexible Nickel Coated Steel Sheets for

Nov 27, 2019 · flexible Ni-coated steel sheet to prevent cracking during forming of battery cases. SUPERNICKELTM shows hig er coverage compared to an ordinary Ni-coated steel sheet

Get Started

What are the features of pure nickel strip for lithium-ion batteries?

2. If there is a battery spot welding machine for lithium-ion battery packs, spot welding can be used for comparison. The higher current is pure nickel sheet, and the lower current is nickel

Get Started

Understanding Nickel Strips and Their Function

May 8, 2025 · The nickel strip of battery pack plays a crucial role as a conductive connector, providing exceptional electrical conductivity while preserving the

Get Started

Pure Nickel Strip or Nickel Plated Steel to DIY

In the salt spray test, the corrosion resistance of pure nickel strips is obviously better than that of nickel plated steel. If the lithium battery pack is often used in

Get Started

Nickel Strip | High Purity 99.98% | Nickel Strip

Nickel Strip Battery Applications Our nickel strip products are mainly used to connect multiple NiMh, NiCd or Li-Ion batteries into a battery pack. Other

Get Started

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to

Get Started

Nickel Strip,nickel Sheet,nickel Metal,nickel Plate

Pure Nickel Strip 4P 5P 6P 7P 8P Bus Bar Coil Lithium-Ion Battery Pack Assembly Strip Application: Nickel sheet : This product is mainly used in the

Get Started

Choosing the Right Welding Materials for Battery Pack

Aug 22, 2024 · Learn how to choose the best welding materials for your battery pack assembly, including nickel strips, copper strips, and pre-tabbed cells.

Get Started

What are the features of pure nickel strip for lithium-ion batteries?

4. Pure nickel strip has good electrical conductivity and low internal resistance. It is often used as battery connection sheet, lead sheet, and busbar for 18650 and 21700 lithium-ion battery

Get Started

LITHIUM BATTERIES 101

Apr 28, 2022 · Lithium vs. lead-acid batteries for trolling motors Trolling motor thrust vs. horsepower explained Pounds of thrust Horsepower Power rating Trolling motor pound thrust

Get Started

What thickness nickel plate needed for 135Ah

Jan 17, 2024 · I have made a number of E-bike batteries - the nickle plate thickness is picked based on the max amperage per cell you will move. a

Get Started

Nickel Battery Technologies

May 16, 2024 · Nickel battery technologies have revolutionized the way we store and use energy, offering a range of solutions for various applications. From

Get Started

How Nickel, Copper, and Aluminum Determine

Feb 5, 2025 · Compare Copper vs. Nickel for lithium battery connection tabs. Learn about conductivity, corrosion resistance, weldability, and cost to choose

Get Started

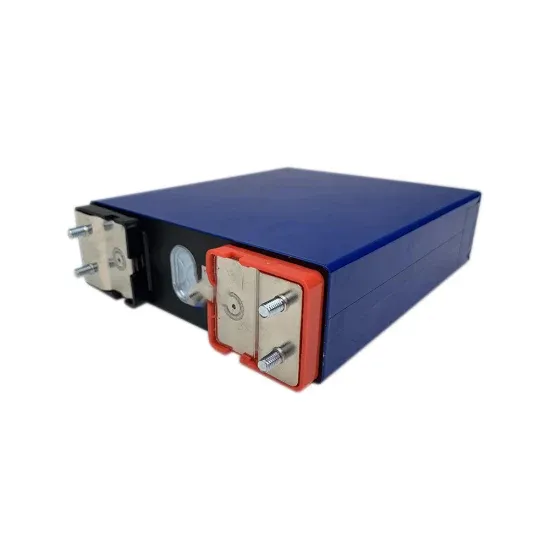

Thickness of nickel sheet in lithium battery pack

Pouch lithium-ion batteries with a capacity of 16 Ah were used in this study; six batteries were assembled in a 2 × 3 structure as the battery module. The battery modules are arranged

Get Started

SHONAN Pure Nickel Strip 99.6% Nickel, 2

Oct 27, 2018 · SHONAN Pure Nickel Strip 99.6% Nickel, 2 Inches Nickel Strips, 0.15x6x50mm Soldering Tabs for High Capacity 18650 Lithium Battery Pack,

Get Started

What Are Used in Lithium Batteries elements? | Expert Guide

Feb 17, 2025 · Another promising cathode material is lithium nickel manganese cobalt oxide (NMC), which combines nickel, manganese, and cobalt in varying ratios to optimize energy

Get Started

Understanding the Role and Importance of Nickel Strip in Battery

Apr 23, 2024 · Nickel strip, often referred to as nickel tape or nickel ribbon, Best price for SMD/SMT Pad Pure Nickel Tab plays a crucial role in the construction and performance of

Get Started

NIONSUPPLY 100pcs 99.6% Pure Nickel Strips Nickel Tapes Nickel Sheet

Jun 30, 2022 · 100pcs 99.6% Pure Nickel Strips Nickel Tapes Nickel Sheet Soldering Tabs for DIY 18650 21700 Lithium Battery Pack Li-Po Battery Connector Tab Battery Cell Spot Welding

Get Started

Nickel Sheet Price,nickel Sheet Manufacturers-Tmax Battery

Pure Nickel Strip 4P 5P 6P 7P 8P Bus Bar Coil Lithium-Ion Battery Pack Assembly Strip Application: Nickel sheet : This product is mainly used in the manufacture of mobile power,

Get Started

Best Conductors to Use For Battery Pack

Jan 3, 2023 · If you are building a small, low-current battery pack or a large, medium-current battery pack, nickel is the best metal to use. If, however, you

Get Started

6 FAQs about [What nickel sheet is used in lithium battery pack]

How to choose a nickel strip for a lithium battery?

The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips and nickel plated steel. What is the difference between their performance and actual use?

What is nickel strip?

Nickel strip is a material often used in series and parallels lithium battery packs. The width and material of the nickel strip should be selected according to the current of the lithium battery pack. In terms of material, there are two commonly used nickel strips: pure nickel strips and nickel plated steel.

What is the internal resistance of pure nickel sheet?

The internal resistance of pure nickel sheet is lower than that of nickel-plated steel sheet. If there is a battery spot welding machine for lithium-ion battery packs, spot welding can be used for comparison. The higher current is pure nickel sheet, and the lower current is nickel-plated steel sheet.

Which one is lighter, pure nickel strip or nickel-plated steel sheet?

The lighter is pure nickel strip for the same size, it can be compared by weight, and the heavier is nickel plated steel sheet.

How ni-coated steel sheets can improve the safety of Li-ion batteries?

a battery ca e with high Ni coverage can improve the safety of Li-ion batteries.1. IntroductionNi-coated steel sheets have been used for cases of various types of batteries containing concentrated alkaline electrolyte solutions, such as alkaline manganese batteries, Ni-Cd batteries, and Ni-MH batter

Does nickel plated steel rust better than pure nickel strips?

Pure nickel strip has strong corrosion resistance. In the salt spray test, the corrosion resistance of pure nickel strips is obviously better than that of nickel plated steel. If the lithium battery pack is often used in an environment with high humidity, nickel plated steel will easily rust, but pure nickel strips will not.

Related Articles

-

What do you need to build a lithium battery pack

What do you need to build a lithium battery pack

-

What is the mc mark on the front of the lithium battery pack

What is the mc mark on the front of the lithium battery pack

-

Can 48v lithium battery pack be used for electric tricycles

Can 48v lithium battery pack be used for electric tricycles

-

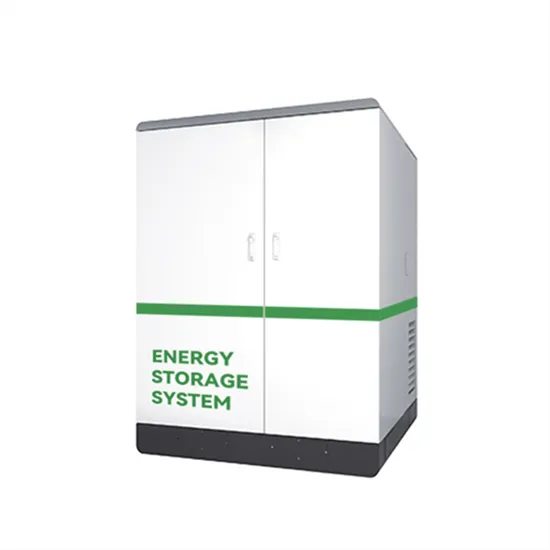

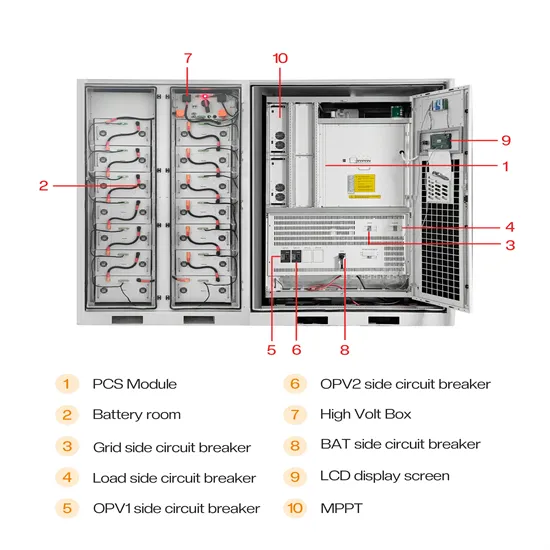

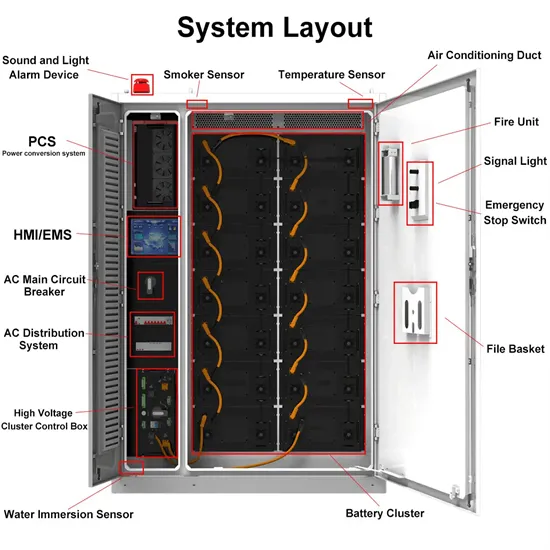

What is the lithium battery energy storage cabinet used for

What is the lithium battery energy storage cabinet used for

-

What brand of lithium battery pack is good

What brand of lithium battery pack is good

-

Kenya lithium battery battery pack

Kenya lithium battery battery pack

-

What is the prospect of lithium battery station cabinet

What is the prospect of lithium battery station cabinet

-

Saint Lucia 84v lithium battery pack

Saint Lucia 84v lithium battery pack

-

Does it need to balance the voltage when making a lithium battery pack

Does it need to balance the voltage when making a lithium battery pack

-

3-series high-rate lithium battery pack

3-series high-rate lithium battery pack

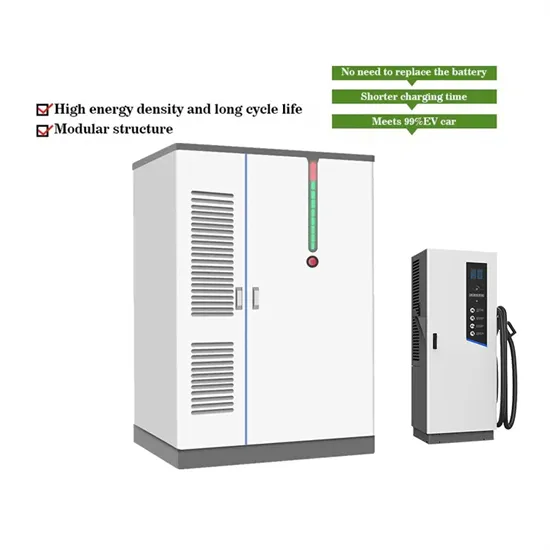

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.