Battery Balancing: Techniques, Benefits, and How It Works

Step 1: Charge each battery individually to its full capacity using a suitable charger. Step 2: Use a voltmeter to measure the voltage of each battery. It is best to keep the voltage difference of

Get Started

Lithium Ion Battery Voltage Explained:

Dec 31, 2024 · The use of this chart helps the battery consumers to analyze the remaining energy capacity and the real-time voltage levels corresponding to

Get Started

How Does A BMS Balance A Lithium Battery?

May 10, 2023 · There are many reasons the cells in a lithium-ion battery need to be balanced. If a cell group is lower than the others, the BMS will put the

Get Started

What''s The Cycling And Float Of a Lithium

Dec 29, 2023 · Should you float a lithium battery? While floating is a common practice for lead-acid batteries, it is generally not recommended for lithium

Get Started

LiFePO4 Cell Balancing & How To Balance

What is LiFePO4 cell balancing and why does it matter? We take a look at how to balance LiFePO4 cells and get teh best out of your battery.

Get Started

Battery Balancer Guide | What It Is & How It

Aug 15, 2024 · What is the indication method when the equalizer working? the indication is performed by the led Indicator, as zhcsolar has two types of

Get Started

Techniques for Balancing Batteries-Improve

Battery balancing is the process of equalizing the charge among individual cells within a battery or between batteries in a group to maintain consistent voltage

Get Started

Making a Li-Ion battery pack

Jun 6, 2020 · This post shows the steps involved in making a 2S pack with 21700 cells. This guide is also relevant for constructing with 18650 cells. Materials

Get Started

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get Started

Everything You Need to Know About Battery Balancing

Apr 3, 2025 · In battery systems, cells are often connected in series to achieve higher voltage levels that meet the load requirements. For example, a battery pack consists of 16 individual

Get Started

Debunking Lithium-Ion Battery Charging Myths:

May 5, 2025 · Explore the truth behind common lithium-ion battery charging myths with our comprehensive guide. Learn the best practices to enhance

Get Started

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · A parallel BMS regulates the current flow between 2 or multiple batteries connected in parallel, learn how it works and how to connect it.

Get Started

Battery Equalization Guide 2023 | ZHCSolar

Mar 28, 2023 · The ultimate guide to understanding what battery equalization and equalizer is, balancing the battery with an additional balancing device for your

Get Started

How Are Lithium Batteries Made? A

Sep 25, 2023 · Introduction With tech zooming ahead, lithium batteries are powering up just about everything. From our phones to our electric rides,

Get Started

A complete analysis of lithium battery balancing

May 25, 2025 · When the battery voltage difference reaches more than 20mV, balancing is required, especially in the range of 20-50mV, the balancing effect

Get Started

Why Proper Cell Balancing is Necessary in

When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell

Get Started

How to solve the problem if we encounter

3 days ago · Battery balancing is a crucial aspect of ensuring the optimal performance, longevity, and safety of your lithium battery systems. Whether

Get Started

How to Build A Battery Pack From 18650 Cells

Mar 30, 2022 · To make the battery pack you need, you must first know what voltage, amp hours, and current carrying capacity the battery needs to have.

Get Started

A Better Life with Batteries – Achieving Energy Balance

6 days ago · In electric vehicle (EV) batteries, a set of cells is assembled into a module, and multiple modules are assembled to form a pack. Each cell must maintain a consistent voltage

Get Started

How to Top Balance LiFePO4 Cells

Jun 26, 2025 · Learn how to top balance your LiFePO4 cells for optimal performance and longevity. Follow these steps and safety tips to ensure

Get Started

How Do You Balance Lithium Battery Packs In

May 10, 2023 · To balance lithium batteries in series, you would need to charge the batteries individually to the same charge voltage. Unlike cells in series that

Get Started

Li-ion Battery Pack Balance

The meaning of battery balance is to keep the voltage of the lithium-ion battery cell or the voltage deviation of the battery pack within the expected range. So as to ensure that each battery cell

Get Started

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack is a critical skill for anyone working with modern energy storage systems. Whether you''re powering an electric vehicle, a renewable energy

Get Started

The Significance of Cell Balancing in Lithium Packs

Apr 25, 2024 · Cell balancing is a technique used to equalize the charge levels of individual cells within a lithium-ion battery pack. In a typical battery pack,

Get Started

What are Cell Balancing Techniques and How to

Jan 4, 2019 · Why do we need Cell Balancing? Cell balancing is a technique in which voltage levels of every individual cell connected in series to form a

Get Started

How to Build a Lithium Battery: Step-by-Step for

Feb 22, 2024 · 1. Prepare materials and tools The following materials and tools are required to assemble the lithium battery pack. a. Lithium battery cell:

Get Started

Complete Guide to Lithium Battery Protection

Feb 21, 2024 · A battery PCB board is an essential component within the protection system of lithium-ion and other rechargeable batteries. It is

Get Started

Why Balancing Cells in a LiFePO4 Battery Is

Nov 27, 2024 · A key factor in ensuring their longevity and efficiency is cell balancing—the process of equalizing the voltage levels of individual cells in a

Get Started

The Complete Guide to Lithium-Ion Battery

Nov 14, 2023 · The Importance of Voltage in Lithium-Ion Batteries Now, let''s talk about voltage. In simple terms, voltage is the electrical pressure that pushes

Get Started

Will Batteries Balance in Parallel? (What Does a

Nov 2, 2023 · The quick answer is yes, batteries will balance in parallel. However, there are a few things to keep in mind when connecting batteries in parallel.

Get Started

LiFePO4 Battery Balancing

Jul 10, 2023 · LiFePO4 batteries are the best that the technology has on offer right now. Their long lifespan and highest value for money make users replace

Get Started

The Ultimate Guide to Lithium Battery Equalizers

5 days ago · Lithium battery equalizers play a crucial role in extending the life and performance of lithium-ion battery packs. This comprehensive guide provides an in-depth understanding of

Get Started

Why Proper Cell Balancing is Necessary in

Contributed Commentary by Anton Beck, Battery Product Manager, Epec When a lithium battery pack is designed using multiple cells in series, it is very

Get Started

Everything You Need to Know About Battery Balancing

Apr 3, 2025 · Balancing is equalizing the voltage of individual cells in a battery system. It means bringing each cell''s voltage closer to the pack''s average voltage. Why is Balancing

Get Started

Battery Cell Balancing: What to Balance and How

Jun 26, 2007 · In fact, many common cell balancing schemes based on voltage only result in a pack more unbalanced that without them. This presentation explains existing underlying

Get Started

6 FAQs about [Does it need to balance the voltage when making a lithium battery pack ]

Why is a lithium battery pack designed with multiple cells in series?

Contributed Commentary by Anton Beck, Battery Product Manager, Epec When a lithium battery pack is designed using multiple cells in series, it is very important to design the electronic features to continually balance the cell voltages. This is not only for the performance of the battery pack, but also for optimal life cycles.

Does a lithium ion battery have a balance problem?

If you built a lithium-ion battery and its capacity is not what you expect, then you more than likely have a balance issue. While it's true that cells connected in parallel will find their own natural balance, the same is not true for cells wired in series. Battery cells in series have no way of transferring energy between one another.

What is battery balance?

The meaning of battery balance is to keep the voltage of the lithium-ion battery cell or the voltage deviation of the battery pack within the expected range. So as to ensure that each battery cell remains in the same state during normal use, in order to avoid overcharging and over-discharging.

Why is battery balancing important?

Therefore, balancing improves the Depth of Discharge (DOD), making the battery system more efficient. It's important to note that balancing only equalizes cell voltages to the average value of the pack and does not alter the inherent characteristics of the cells.

Do you know how to balance a lithium battery pack?

Whether you are new to battery building or a seasoned professional, it's totally normal to not know how to balance a lithium battery pack. Most of the time when building a battery, as long as you use a decent BMS, it will balance the pack for you over time. The problem is, this can take a very, very long time.

How to keep a lithium ion battery balanced?

In Li-ion batteries which have very low self-discharge and therefore accumulative unbalance per cycle is usually less than 0.1%, bypass current of internal FETs is sufficient to keep the pack continuously balanced.

Related Articles

-

Balanced voltage of lithium battery pack

Balanced voltage of lithium battery pack

-

How much voltage is used to charge a 7 4v lithium battery pack

How much voltage is used to charge a 7 4v lithium battery pack

-

Lithium battery pack protection voltage

Lithium battery pack protection voltage

-

General voltage of power lithium battery pack

General voltage of power lithium battery pack

-

What do you need to build a lithium battery pack

What do you need to build a lithium battery pack

-

The higher the voltage of the lithium battery pack the safer it is

The higher the voltage of the lithium battery pack the safer it is

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

900v high voltage lithium battery pack

900v high voltage lithium battery pack

-

Standard voltage of lithium battery pack

Standard voltage of lithium battery pack

-

Which Paraguayan lithium iron phosphate battery pack decays faster

Which Paraguayan lithium iron phosphate battery pack decays faster

Commercial & Industrial Solar Storage Market Growth

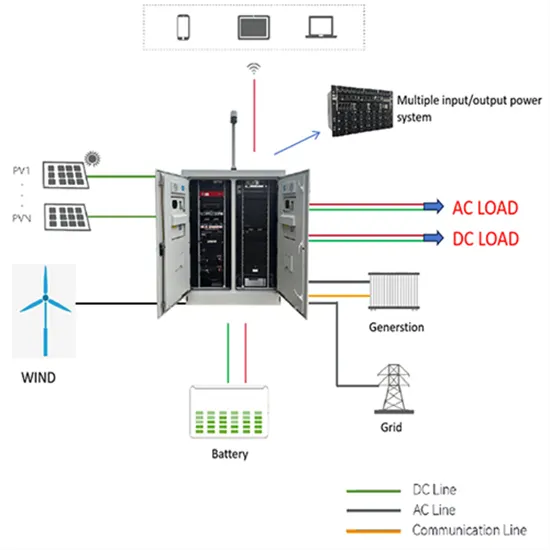

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.