Lithium-Ion Battery Pack Protection Circuit Analysis

Feb 8, 2025 · These circuits ensure the safe operation of the battery pack by preventing damage from excessive charging, discharging, or temperature. Q: How does the protection circuitry in a

Get Started

How to choose a suitable lithium battery protection board

Oct 9, 2023 · The voltage of the battery pack = battery voltage of a single string * number of strings of batteries, according to the number of strings to choose the right voltage protection

Get Started

BU-808a: How to Awaken a Sleeping Li-ion

Nov 3, 2021 · Discard the pack if the voltage does not rise to a normal level within a minute while on boost. Do not boost lithium-based batteries back to life that

Get Started

Lithium Battery Packs: Choosing the Protection

May 31, 2023 · Key Takeaways Protection Boards Are Essential for Lithium Safety: Due to lithium''s high energy density and volatile chemistry, protection

Get Started

Battery protection units (BPU) | Infineon Technologies

A battery protection unit (BPU) prevents possible damage to the battery cells and the failure of the battery, enhancing the useful operating life of lithium-ion batteries by protecting the battery

Get Started

Lithium Ion Cell Protection

Dec 14, 2015 · Two important parameters in battery ICs are overvoltage threshold and undervoltage threshold. These numbers are the voltage levels at their

Get Started

Lithium-ion Battery Protection ICs

Jul 30, 2025 · A lithium-ion battery protection IC is an IC that monitors overcharge, overdischarge, and overcurrent to protect lithium-ion batteries,

Get Started

Battery Protection

Default DescriptionImportance Of Battery Protection In BMS, battery protection plays a key role. Particularly, lithium-ion variants, which are a type of high-energy storage devices, and

Get Started

Understanding Lithium Battery Over Discharge Protection:

Mar 6, 2025 · Choose the Right Components Whether designing a battery pack from scratch or modifying an existing one, selecting the right components is vital. Invest in reliable BMS units

Get Started

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 11, 2024 · One Cell Lithium-ion/Polymer Battery Protection IC General Description The LN8231 provides a high integration solution for lithium-ion/polymer battery protection. The

Get Started

LiFePO4 BMS Selection Guide: Matching Your Pack''s Voltage,

Aug 19, 2025 · LiFePO4 BMS Selection Guide: Matching Your Pack''s Voltage, C-Rating, and Current Lithium iron phosphate (LiFePO4) batteries have become one of the most reliable and

Get Started

Lithium-Ion Battery Circuitry Is Simple

Oct 10, 2022 · The DW01 is an IC that monitors the voltage of your cell and the current going to and from it, and the 8205A is two N-FETs in a single package,

Get Started

Overvoltage protection vs. Undervoltage

May 26, 2024 · Why Is Overvoltage Protection Important? Prevents Damage: Overcharging can cause physical damage to the battery cells, leading to

Get Started

How to Choose the Right Battery Protection Board for Lithium

Dec 4, 2024 · Battery Voltage: The protection board should be able to handle the battery''s nominal voltage, full-charge voltage, and minimum discharge voltage. For example, a typical

Get Started

BU-304: Why are Protection Circuits Needed?

Apr 14, 2023 · Further layers of safeguards can include solid-state switches in a circuit that is attached to the battery pack to measure current and voltage and

Get Started

Battery Pack Cell Voltage Difference and

Jan 18, 2021 · If there is a BMS or other protection circuit measures, any cell voltage will reach the limit of undervoltage protection, and the protection circuit

Get Started

Lithium – Ion Battery Protection System

May 18, 2023 · The automotive business is admittedly serious regarding electrical Vehicles now also the most significant rudiments of associate EV, the Battery Pack. Cost-wise, it constitutes

Get Started

How BMS Overvoltage Protection Guard the

Sep 21, 2023 · BMS overvoltage protection is used to prevent a battery or battery pack from rising above the voltage level of a predefined safety limit.

Get Started

10s-16s Battery Pack Reference Design With Accurate

May 11, 2022 · The BQ77216 family of products provides a range of voltage and temperature monitoring including overvoltage (OVP), undervoltage (UVP), open wire (OW), and

Get Started

BMS Protection Functions for Lithium Battery Pack

Sep 10, 2020 · Under-voltage protection also sets some voltage values, below which BMS requires reducing the electric current or cutting off the discharge

Get Started

Lithium-Ion Battery Pack Protection Circuit Analysis

Feb 8, 2025 · Protection Circuitry: A typical lithium-ion battery pack uses a protection circuit to prevent overcharging, overdischarging, and excessive current. This circuitry typically includes

Get Started

One Cell Li-Ion Battery Protection IC

Jul 5, 2023 · General Description The LPB1003 product is a highly integrated solution for Li-Ion battery protection. It includes advanced power MOSFETs, precision voltage detection circuitry

Get Started

How to Choose the Right Battery Protection Board for Lithium

Dec 4, 2024 · Learn how to choose the right lithium battery protection board based on factors like battery type, capacity, voltage, and protection features. Ensure your battery''s safety and

Get Started

Complete Guide to Lithium Battery Protection Board

Feb 21, 2024 · Over-discharge Protection: When a lithium-ion battery is discharged too much (usually below 2.5V or 3.0V per cell), it can cause irreversible damage to the cells. The battery

Get Started

Lithium Battery Pack Protection and Control

Market trends and drivers Safety and ageing concerns in Lithium battery applications highlight the critical need for advanced protection and control solutions in the market. Adoption of electric

Get Started

Comprehensive Guide to Lithium Battery Cell

May 21, 2025 · Understand lithium battery cell voltage during charging and discharging, including safe ranges, cutoff limits, and how voltage impacts

Get Started

What is a BMS protection board of lithium battery?

A BMS protection board for li-ion is responsible for monitoring and protecting the battery cells. It has a number of protection settings.

Get Started

Simple Undervoltage and Overcurrent Protection

Mar 29, 2021 · Introduction To safely utilize lithium-ion or lithium polymer batteries, they must be paired with protection circuitry capable of keeping

Get Started

Battery protection selection guide

May 24, 2025 · For that, Infineon ofers a wide range of battery protection solutions that, under stressful conditions, increase lifetime and eficiency of lithium batteries. The battery protection

Get Started

One Cell Lithium-ion/Polymer Battery Protection IC

Oct 11, 2024 · T he LN8231 monitors the voltage and current of a battery and protects it from being damaged due to overcharge voltage, over-discharge voltage, over-discharge current,

Get Started

6 FAQs about [Lithium battery pack protection voltage]

How to protect a lithium battery?

Use special lithium battery protection chip, when the battery voltage reaches the upper limit or lower limit, the control switch device MOS tube cut off the charging circuit or discharging circuit, to achieve the purpose of protecting the battery pack. Characteristics: 1. Only over-charge and over-discharge protection can be realized.

What is a lithium battery protection circuit?

The protection circuit ensures the voltage does not exceed the safe limits set by the manufacturer. For example, a common lithium-ion battery operates between 3.0V and 4.2V per cell. Exceeding these limits can lead to serious safety risks like overheating, leakage, or even fires. A typical lithium battery protection circuit includes:

What is a lithium battery protection board?

A lithium battery protection board typically includes various essential components like voltage regulators, transistors, resistors, and microcontrollers. The protection circuit ensures the voltage does not exceed the safe limits set by the manufacturer. For example, a common lithium-ion battery operates between 3.0V and 4.2V per cell.

Are lithium batteries safe?

Lithium batteries have the advantage of high energy density. However, they require careful handling. This article discusses important safety and protection considerations when using a lithium battery, introduces some common battery protection ICs, and briefly outlines selection of important components in battery protection circuits. Overcharge

Why should a battery pack be protected?

The battery pack must be protected against all these situations. Good measurement accuracy is always required, especially the cell voltage, pack current, and cell temperature. Precision is necessary for accurate protections and battery pack state of charge (SoC) calculations.

What is the primary protection on a battery pack?

It contains both primary and secondary protections to ensure safe use of the battery pack. The primary protection protects the battery pack against all unusual situations, including: cell overvoltage, cell undervoltage, overtemperature, overcurrent in charge and discharge, and short-circuit discharge.

Related Articles

-

Balanced voltage of lithium battery pack

Balanced voltage of lithium battery pack

-

How much voltage is used to charge a 7 4v lithium battery pack

How much voltage is used to charge a 7 4v lithium battery pack

-

The higher the voltage of the lithium battery pack the safer it is

The higher the voltage of the lithium battery pack the safer it is

-

Standard voltage of lithium battery pack

Standard voltage of lithium battery pack

-

General voltage of power lithium battery pack

General voltage of power lithium battery pack

-

Does it need to balance the voltage when making a lithium battery pack

Does it need to balance the voltage when making a lithium battery pack

-

Which lithium battery pack has a higher voltage

Which lithium battery pack has a higher voltage

-

Lithium battery pack fixed

Lithium battery pack fixed

-

How much does a lithium battery pack for energy storage cost

How much does a lithium battery pack for energy storage cost

-

Fire protection requirements for lithium battery energy storage cabinets

Fire protection requirements for lithium battery energy storage cabinets

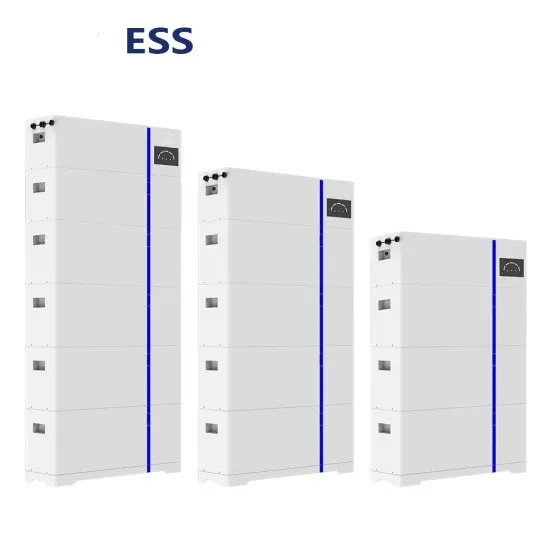

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

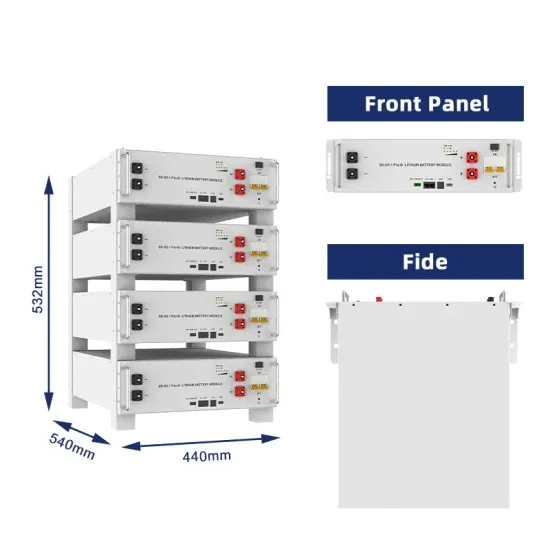

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.