Standard Specifications for Depth of Suspended Battery

What do you need to know about battery cabinets? Battery cabinets shall be provided with exterior labelsthat identify the manufacturer and model number of the system and electrical

Get Started

KEN''S KORNER

Dec 19, 2014 · 16 UPS System Battery Room Safety Issues At the heart of any UPS system supporting a mission critical facility is the battery. IEEE, OSHA,

Get Started

Understanding Biosafety Cabinets: Types, Airflow, and

Apr 29, 2025 · Explore the essentials of biosafety cabinets, including their types, airflow dynamics, and key maintenance practices for optimal safety.

Get Started

The Above Ceiling Inspection Part 1.

Jul 1, 2025 · Make sure there are no flexible cords used above the suspended ceiling to comply with NEC ® 400.12. This also means that condensate pumps

Get Started

Cables Installed in Suspended Ceilings: Technical

Jan 14, 2018 · Suspended ceilings are often provided in commercial and similar premises. They generally consist of a grid of light metal bars, usually having

Get Started

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Get Started

Basic Principles for Suspending Loudspeaker Systems

Contractors and sound installers hang loudspeaker equipment in public meeting places and performing arts facilities as a matter of routine. This Technical Note L details rigging practices

Get Started

The Ultimate Guide to Lithium-Ion Battery

Mar 21, 2025 · Capacity Requirements: Ensure the cabinet accommodates the quantity and size of batteries used in your workplace. Regulatory Compliance:

Get Started

Tips for Designing Battery Cabinets/Enclosures | SBS Battery

Jan 16, 2025 · To calculate the minimum height of the cabinet, use the general formula above. For the length, if a fan is required, factor in 3" of extra space per side or 6" total. Example: a 45"L

Get Started

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Get Started

How to correctly install lithium battery energy

Mar 25, 2024 · We want to ensure that the voltage rating of the lithium battery energy storage cabinet matches the installation site''s electrical specifications.

Get Started

A Quick Guide To Determining The Need For

Mar 15, 2023 · When you need to minimise spillage during decanting, handling and location transfer, drum handling bunding is a great option. These bunding

Get Started

Safe Clearances for Electrical Equipment:

Terms You Should Know: Working space: The front clearance, side clearance, and height clearance requirements for electrical equipment that provide a safe

Get Started

What are the OSHA Requirements for Battery

Oct 16, 2023 · Logistical Challenges: Batteries might need to be transported between ships and the terminal. Safe handling practices must be established,

Get Started

Biological Safety Cabinets: What you need to know for

May 24, 2017 · AS 2252.4 - 2010: Controlled environments Part 4: Biological safety cabinets Class I and II – Installation and use Previously known as AS2647-2000, this Standard is an

Get Started

What does suspended mean on a battery report?

May 6, 2020 · What does suspended mean on a battery report? Suspended: The device is in hibernation mode (after 6 hours standby the device hibernates).

Get Started

Choosing the Right Battery Storage Cabinet: A

Jun 5, 2025 · Before selecting a lithium battery charging cabinet, evaluate your specific operational needs, charging habits, and site layout. Matching your

Get Started

Justrites Guide to Safe Grounding and Bonding

Electrical grounding and bonding are important safety practices for preventing static discharge and reducing the possibility of a fire. But the electrical

Get Started

Do and don''ts of biosafety cabinet?

Oct 11, 2024 · Why is the use of biosafety cabinets important? Biological safety cabinets (BSCs) provide effective primary containment for work with infectious material or toxins when they are

Get Started

How Battery Racks And Cabinets Can Help You Store Batteries

Understanding The Environmental Concerns And Safe Handling Of Lead Batteries Lead-acid batteries need to be properly ventilated and kept at a constant temperature. When cells are

Get Started

Battery Cabinets vs. Battery Racks

Aug 27, 2018 · Battery cabinets must enclose the batteries behind locked doors accessible only to authorized personnel. As long as the cabinets are kept

Get Started

How to Install and Set Up a Battery Storage Cabinet at Home

Apr 19, 2025 · Discover the components and benefits of battery storage cabinet systems, including lithium-ion advantages, placement considerations, ventilation needs, and cost

Get Started

1926.441

Aug 15, 2025 · Facilities for quick drenching of the eyes and body shall be provided within 25 feet (7.62 m) of battery handling areas. Facilities shall be provided for flushing and neutralizing

Get Started

Do Lithium Ion Batteries Require A Battery Room? Storage

Apr 16, 2025 · Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements. Store batteries

Get Started

UPS Systems

Dec 19, 2014 · Battery Remote Monitoring Alarm System Issues: standards affecting UPS system batteries. Some address the battery while others address the room or associated equipment.

Get Started

6 FAQs about [How high does the suspended battery cabinet need to be to be used ]

How far apart should IQ batteries be stacked?

Enphase IQ Battery 3, 3T, 10, and 10T test was conducted at the manufacturers recommended mounting distances with a minimum of 6” between vertically stacked units, 1” horizontally between IQ Battery 3/3T, and 6” clearance on the sides for IQ Battery 10/10T. The IQ Battery datasheets detail that they have been certified to UL9540A.

What are the safety requirements related to batteries & Battery rooms?

Employers must consider exposure to these hazards when developing safe work practices and selecting personal protective equipment (PPE). That is where Article 320, Safety Requirements Related to Batteries and Battery Rooms comes in.

Do lithium ion batteries need a battery room?

Lithium-ion batteries need a battery room if their capacity exceeds 20 kWh, according to fire codes. NFPA 855 outlines ventilation and safety requirements. Store batteries at a temperature of 59°F (15°C). Also, refer to NFPA 70E for further safety guidelines, and ensure proper exhaust ventilation for off-gas events.

What are the requirements for a battery handling facility?

Floors shall be of acid resistant construction unless protected from acid accumulations. Face shields, aprons, and rubber gloves shall be provided for workers handling acids or batteries. Facilities for quick drenching of the eyes and body shall be provided within 25 feet (7.62 m) of battery handling areas.

What standards are used in a battery room?

Common standards in the battery room include those from American Society of Testing Materials (ASTM) and Institute of Electrical and Electronic Engineers (IEEE). Model codes are standards developed by committees with the intent to be adopted by states and local jurisdictions.

What are OSHA regulations for battery handling and storage?

OSHA sets forth regulations that ensure worker safety during battery handling and storage. These include requirements for personal protective equipment and proper training for employees working with batteries.

Related Articles

-

How long can the battery cabinet mobile power supply be used

How long can the battery cabinet mobile power supply be used

-

How much current is normal in a battery cabinet

How much current is normal in a battery cabinet

-

How to use the lithium battery storage cabinet

How to use the lithium battery storage cabinet

-

How to make battery cabinet production equipment

How to make battery cabinet production equipment

-

How to make a load-bearing plan for the battery cabinet

How to make a load-bearing plan for the battery cabinet

-

How to calculate the electricity fee of liquid-cooled energy storage battery cabinet

How to calculate the electricity fee of liquid-cooled energy storage battery cabinet

-

How to charge the new energy battery cabinet in Papua New Guinea

How to charge the new energy battery cabinet in Papua New Guinea

-

How to charge the Hargeisa new energy battery cabinet

How to charge the Hargeisa new energy battery cabinet

-

Communication high voltage battery energy storage cabinet working price

Communication high voltage battery energy storage cabinet working price

-

How big of a circuit breaker should a battery cabinet be equipped with

How big of a circuit breaker should a battery cabinet be equipped with

Commercial & Industrial Solar Storage Market Growth

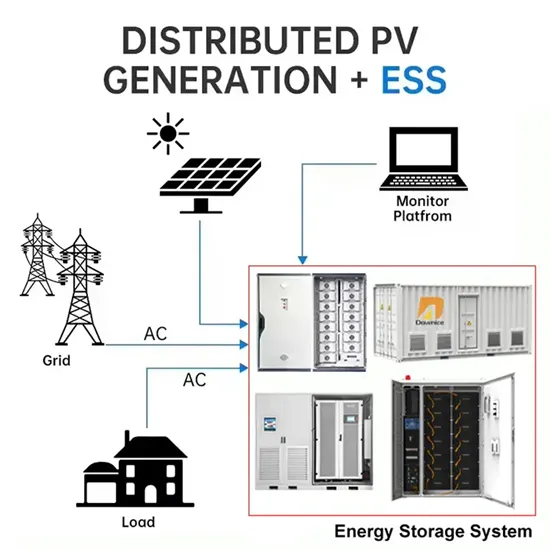

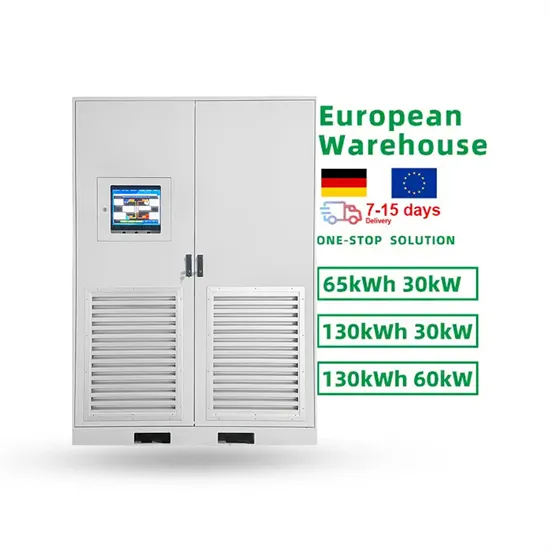

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.