Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Get Started

What equipment is used to make energy storage devices?

Feb 15, 2024 · In the realm of energy storage solutions, battery manufacturing equipment serves as the cornerstone of production. These tools encompass a wide array of machines designed

Get Started

Lithium battery energy storage cabinet production tutorial

This article discusses cell production of post-lithium-ion batteries by examining the industrial-scale manufacturing of Li ion batteries, sodium ion batteries, lithium sulfur...

Get Started

Lion Energy building out large energy storage

Oct 14, 2024 · Battery manufacturer Lion Energy is developing a manufacturing line at its Utah facility for battery rack modules (BRM) and large energy

Get Started

Understanding Lithium Ion Battery Manufacture

Jun 28, 2024 · The production of a lithium battery pack is a multifaceted process, involving several crucial steps to guarantee the final product''s quality and

Get Started

The Importance of Aging Cabinets for Battery Packs

Nov 25, 2024 · Aging cabinets are crucial in the development and testing of battery packs used in electric vehicles, energy storage systems, and other applications. By simulating harsh

Get Started

Battery Energy Storage Cabinet Construction Process: From

Storage systems that survived shared three features: heated cabinets, triple-sealed enclosures, and enough insulation to make a Yeti jealous. Now, leading manufacturers bake extreme

Get Started

From Raw Materials to Reliable Power: Inside the Energy

Ever wondered what goes into creating those sleek battery cabinets powering solar farms or backup systems? The energy storage equipment production process is like baking a multilayer

Get Started

How to Create a Workshop Setup for Batch

May 13, 2025 · Create the perfect workshop for cabinet batch production. Our guide shows how to organize your space, select tools, and implement quality

Get Started

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Get Started

Battery production process and equipment

6 days ago · Lithium battery equipment plays a key role in the continuous improvement of lithium battery production technology, lithium battery yield and

Get Started

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

Get Started

Lithium battery module design production

Aug 18, 2025 · This article will introduce you to the characteristics, design and production process, key points, and development trend of lithium battery

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

The EV Battery Manufacturing Process: Step by

Jun 5, 2024 · The battery is the most expensive part in an electric car, so a reliable manufacturing process is important to prevent costly defects. Electric

Get Started

Production process of battery cabinets

Ten technical trends of lithium-ion battery industry Page 5 2.1 Pain points and challenges in the manufacturing process of pole pieces Pain points of coating Pain points of rolling and slitting

Get Started

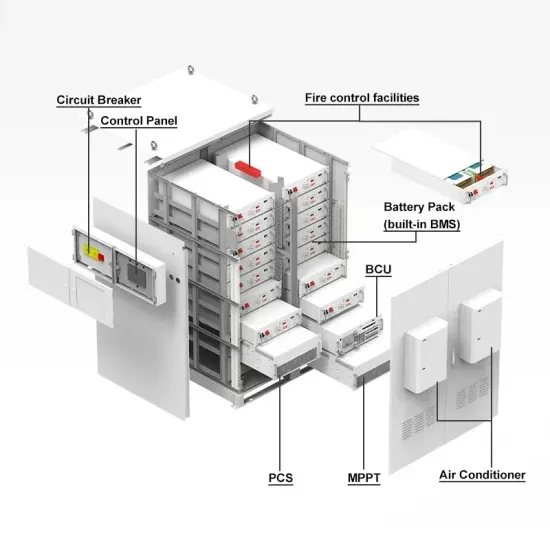

How to design an energy storage cabinet: integration and

Jan 3, 2025 · As the core equipment in the energy storage system, the energy storage cabinet plays a key role in storing, dispatching and releasing electrical energy. How to design an

Get Started

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Get Started

Top 10 Battery Assembly Line Equipment

Mar 23, 2025 · Discover the top 10 battery assembly line factory manufacturer suppliers for 2025. Learn how to select the best equipment for your production

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

Design of cubic battery cabinet production line

The industrial production of lithium-ion batteries usually involves 50+individual processes. These processes can be split into three stages: electrode manufacturing,cell fabrication,formation and

Get Started

MTI Corp --

Flow-Chart of Coin/Pouch/Cylinder Cell by MTI''s Battery Equipment Budget Planning for Laboratory Scale Pouch Cell Line in ONE Glove Box High End & Advanced Pouch Cell

Get Started

Lithium battery energy storage cabinet production tutorial

Lithium secondary batteries store 150-250 watt-hours per kilogram(kg) and can store 1.5-2 times more energy than Na-S batteries,two to three times more than redox flow batteries,and about

Get Started

Company announces nearly $712 million project

Nov 16, 2024 · A battery manufacturer has selected Kentucky for a nearly $712 million project to produce industrial-sized batteries used to store and distribute

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Started

Outdoor Battery Cabinet Manufacturer and

Outdoor battery cabinet protects contents from harmful outdoor elements such as rain, snow, dust, external heat, etc. Plus, it provides protection to personnel

Get Started

Battery cabinet production materials

A well-designed lithium ion battery cabinet includes features like fire-resistant materials, proper ventilation, and integrated safety mechanisms. These features help mitigate

Get Started

What are the lithium battery production

According to the production process of lithium-ion batteries, lithium battery equipment can be mainly divided into front-end equipment, mid-end

Get Started

Understanding the Lithium

Mar 17, 2025 · In the realm of lithium - battery production and quality control, the lithium - battery aging cabinet plays a crucial role. But what exactly is it? A lithium - battery aging cabinet, also

Get Started

The inconsistency problem mainly stems from the quality variation of raw material, the precision and stability of equipment, and the production environment during the battery manufacturing

Get Started

6 FAQs about [How to make battery cabinet production equipment]

What is the battery manufacturing process?

The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This guide covers the entire process, from material selection to the final product’s assembly and testing.

What are the raw materials for battery production?

The raw materials for battery production, including lithium-ion battery manufacturing, are critical for ensuring high-quality output. The foundation of any battery is its raw materials. These materials’ quality and properties significantly impact the final product’s performance and longevity. Typical raw materials include:

What materials are used to make batteries?

These materials’ quality and properties significantly impact the final product’s performance and longevity. Typical raw materials include: Lithium: Lithium-ion batteries are known for their high energy density and efficiency due to their use in them. Nickel: Essential for nickel-metal hydride (NiMH) and nickel-cadmium (NiCd) batteries.

What makes a battery a good battery?

The foundation of any battery is its raw materials. These materials’ quality and properties significantly impact the final product’s performance and longevity. Typical raw materials include: Lithium: Lithium-ion batteries are known for their high energy density and efficiency due to their use in them.

How do you assemble a battery?

The next step is assembling the battery cells. There are two primary methods: Winding: The anode and cathode foils, separated by a porous film, are wound into a jelly-roll configuration. Stacking: Stack the anode, separator, and cathode layers in a flat, layered structure. 4.2 Cell Enclosure

What is the electrolyte filling process in battery manufacturing?

The electrolyte filling process in battery manufacturing is crucial for performance and safety in lithium-ion batteries. This step involves introducing the electrolyte into the cell and ensuring it saturates the electrodes correctly. Here’s a detailed look at the process: 5.1 Vacuum Filling

Related Articles

-

How much is the battery cabinet production equipment price

How much is the battery cabinet production equipment price

-

How to make a load-bearing plan for the battery cabinet

How to make a load-bearing plan for the battery cabinet

-

What to do if battery cabinet production causes pollution

What to do if battery cabinet production causes pollution

-

How much does a full set of lithium battery equipment cost

How much does a full set of lithium battery equipment cost

-

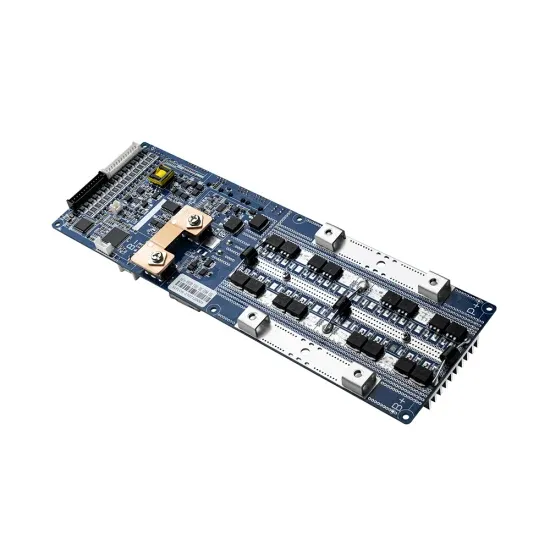

Battery cabinet BMS production line

Battery cabinet BMS production line

-

What are the energy storage battery production equipment

What are the energy storage battery production equipment

-

How long can the battery cabinet mobile power supply be used

How long can the battery cabinet mobile power supply be used

-

What equipment category does the battery cabinet belong to

What equipment category does the battery cabinet belong to

-

How to set quota for battery cabinet commissioning

How to set quota for battery cabinet commissioning

-

How to use the lithium battery storage cabinet

How to use the lithium battery storage cabinet

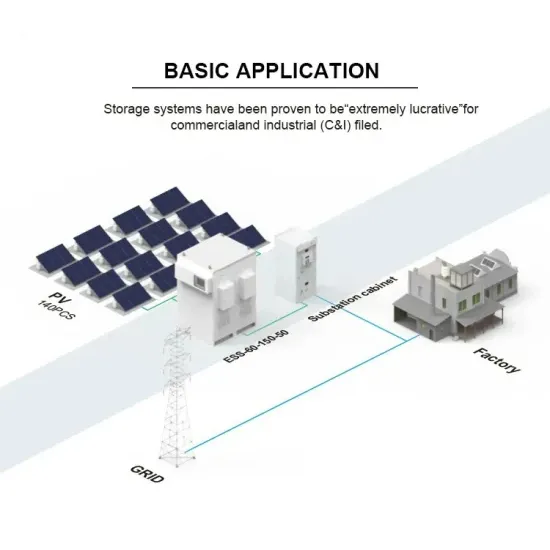

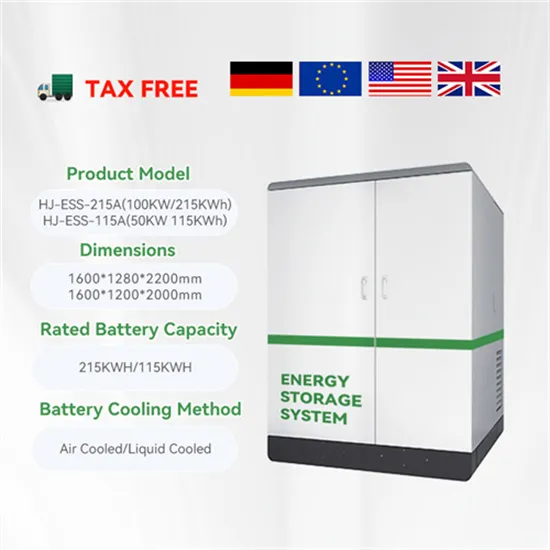

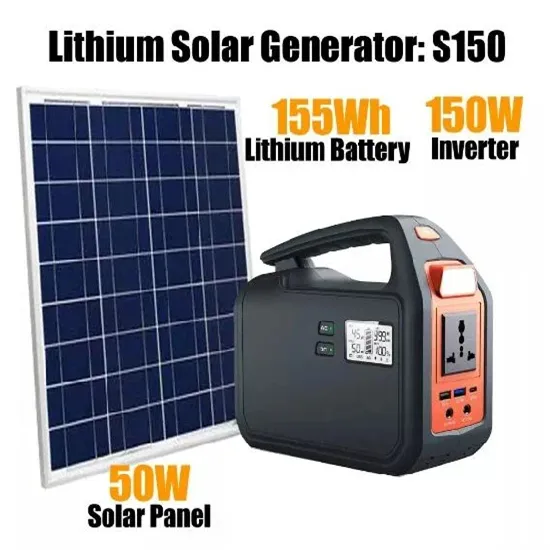

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

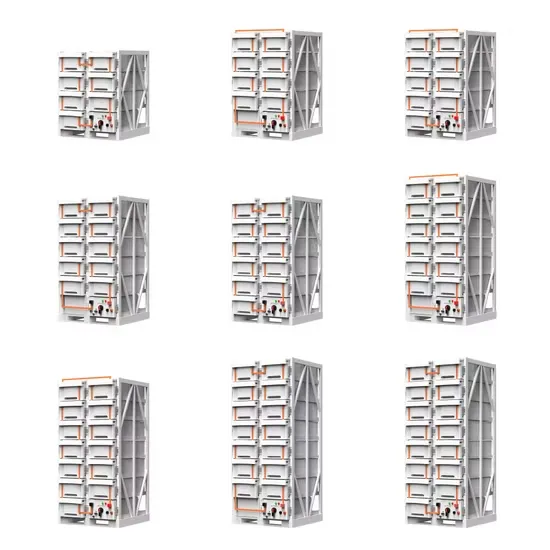

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.