Lithium Battery Pack Assembly Line Manufacturer, BMS

Lithium Battery Pack Assembly Line Supplier, BMS Tester, Cells Capacity Tester Cells Sorting Machine Manufacturers/ Suppliers - Shenzhen Aitop Intelligent Equipment Co., Ltd.

Get Started

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · Automated systems are designed to follow strict safety protocols, minimizing the risk of mishandling or improper assembly of hazardous materials. Conclusion TheLiFePO4

Get Started

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

Get Started

Lithium battery energy storage cabinet production tutorial

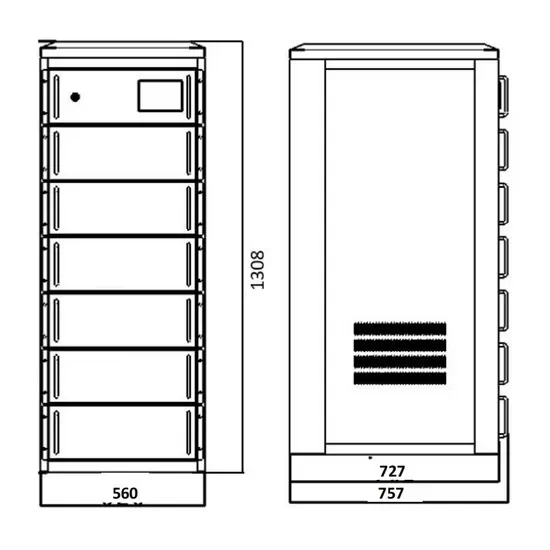

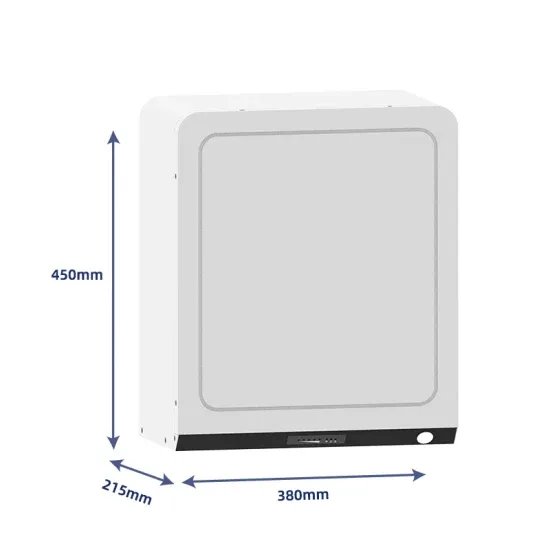

The SBS- Rack/Cabinet mounted lithium energy storage battery, uses high cycle lithium iron phosphate cells, high-performance BMS protection and management battery system, and can

Get Started

Durable Outdoor Battery Swap Cabinet: Compatible with

We''re committed to providing the highest-quality Swapping Cabinet and GPS BMS with the Cloud Server a Chinese national high-tech enterprise has a senior R&D team,dozens of

Get Started

Automotive electronics

Automatic assembly line for BMS in-vchicle products is a highly effcient and automated production line for theproduction of Battery Management System (BMS), a core component in new energy

Get Started

200kWh-241kWh High Voltage Lithium Battery

Aug 19, 2025 · Explore the BSLBATT ESS-GRID Cabinet Series, an industrial and commercial energy storage system available in 200kWh, 215kWh,

Get Started

Battery Module & Pack Manufacturing: Step-by

Apr 19, 2025 · A slave Battery Management System (BMS) is integrated at this stage to monitor the module. 3. Pack Assembly Modules are stacked in series

Get Started

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the comprehensive process of lithium-ion battery assembly, detailing each step from cell grading to final pack testing.

Get Started

Electric Vehicles | Jendamark

Pioneers in the EV Industry Jendamark India is a pioneer in providing customised, indigenously developed assembly line and testing solutions to several electric

Get Started

How to Design a Good Battery Management

4 days ago · Production line testing – Validate sample units built on production line meet specifications through testing and QA. Field configuration –

Get Started

BATTERY CABINETS-Battery Cabinet-KEBOS POWER CO., LTD.-

Battery cabinets for all KEBOS UPS from 1KVA up to 1200KVA Power Range.The Battery cabinet is designed to house standard VRLA Batteries of capacity range from 17AH to 250AH.The

Get Started

Battery Assembly Line Design, Build, and Scaling

We design and implement fully integrated battery assembly lines that streamline module and pack production, ensuring precision, consistency, and scalability.

Get Started

BMS Energy Storage System Cabinet Type Energy Storage Battery

8.BMS:The BMS has protection functions such as voltage, current, and temperature, and uses the system to communicate well with the host;the monitoring unit automatically measures the

Get Started

Battery Management System, Smart Bms, Bms Lifepo4, Bms Wifi

4 days ago · Shenzhen Tuodatong Electronics Co., Ltd. is a national high-tech company specializing in smart BMS (Battery Management System) solutions, integrating R&D,

Get Started

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the Lithium-Ion Battery Assembly Line —how precision, automation, and testing ensure high performance, safety, and reliability in

Get Started

Lithium Battery Tester|li ion pack

Lithium Battery Tester|li ion pack tester|Protection board(BMS) tester|Battery charging and discharging Aging cabinet tester|Life Cycle testing machine|Life

Get Started

Interconnected Battery Cabinet: Universal for Electric Bicycles

We''re committed to providing the highest-quality Swapping Cabinet and GPS BMS with the Cloud Server a Chinese national high-tech enterprise has a senior R&D team,dozens of

Get Started

Production Process of Battery Modules and

PDF | On Oct 25, 2023, Heiner Heimes and others published Production Process of Battery Modules and Battery Packs | Find, read and cite all the research

Get Started

Tertron: Your Partner in Advanced Battery

Choose TERTRON''s automated battery production lines, featuring precision assembly, integrated quality control, and scalability for lithium-ion and other

Get Started

Lithium Battery PACK Production Line Processes

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Started

Battery Assembly Line Design, Build, and Scaling

Re:Build Battery Solutions provides turnkey battery manufacturing solutions, covering facility design, equipment customization, and process optimization to

Get Started

Automatic Li-ion Battery Pack Production Line

Automatic Li-ion battery pack production line is an automated assembly line from cylindrical li-ion cells to semi-finished li-ion battery packs which are ready to

Get Started

How to design an energy storage cabinet: integration and

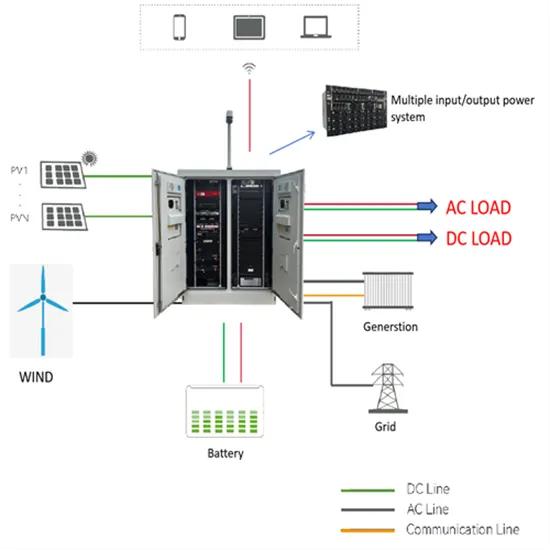

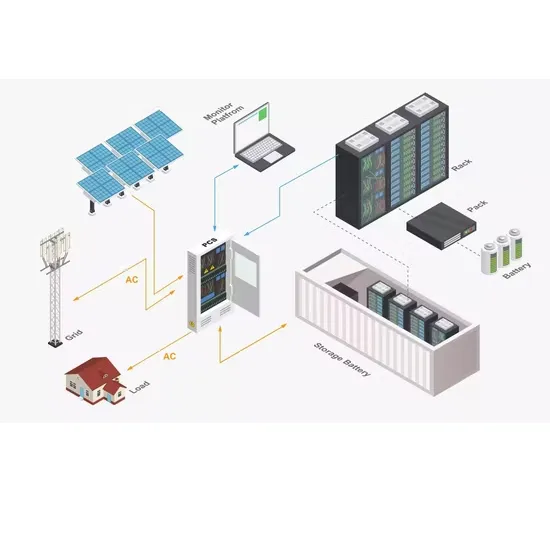

Jan 3, 2025 · Knowledge How to design an energy storage cabinet: integration and optimization of PCS, EMS, lithium battery, BMS, STS, PCC, and MPPT Energy Storage Cabinet is a vital

Get Started

Production of energy storage battery cabinets

Lithium Battery Energy Storage Cabinet Support Customization Lithium Battery Energy Storage Cabinet MK''''s Li-battery storage system features high-voltage output for enhancing energy

Get Started

Battery Production | AVL

May 28, 2025 · To ensure that batteries deliver optimal performance over the longest possible lifetime while meeting strict safety standards, we have developed the AVL Battery TS™ End

Get Started

BMS Battery Pack Production Line, 18650 Lithium Battery

Lithium battery pack is widely used in the consumer electronics market, covering mobile phones, laptops, digital cameras, portable devices,electric vehicles, solar light and so on. Lithium

Get Started

Energy Storage System Solutions-Ampace

Holistic Solutions Covering the entire battery system, including raw materials, cell, module, BMS, pack, leading to integrated battery solutions with superior

Get Started

The Process Behind High-Quality BMS Production

Aug 14, 2025 · A battery assembly line is a system that puts together different parts of a battery, like cells, tabs and modules, into a complete unit. It uses machines, robots and automation to

Get Started

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Learn how to overcome challenges in lithium-ion battery pack assembly with automation, customization, and advanced process control for

Get Started

bms battery production line

The BMS and the battery pack end of line test system can be widely used in battery pack production lines, providing a programmable software platform and customized test items to

Get Started

Related Articles

-

Battery cabinet production line technical solution

Battery cabinet production line technical solution

-

Thailand energy storage cabinet battery production line

Thailand energy storage cabinet battery production line

-

Labeling of battery cabinet automatic production line

Labeling of battery cabinet automatic production line

-

How much does a battery cabinet production line cost per day

How much does a battery cabinet production line cost per day

-

Haiti Energy Storage Cabinet Battery Production

Haiti Energy Storage Cabinet Battery Production

-

Chisinau BMS battery exchange cabinet

Chisinau BMS battery exchange cabinet

-

What to do if battery cabinet production causes pollution

What to do if battery cabinet production causes pollution

-

UPS battery cabinet load-bearing frame production

UPS battery cabinet load-bearing frame production

-

Avalu outdoor communication battery cabinet production equipment

Avalu outdoor communication battery cabinet production equipment

-

Santo Domingo Outdoor Communication Battery Cabinet Production Company

Santo Domingo Outdoor Communication Battery Cabinet Production Company

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.