System Engineering Battery Solutions

Dec 11, 2024 · Especially in the field of battery manufacturing, we offer our customers the entire product range: from cell assembly through the entire battery process to the End of Line test.

Get Started

Battery Production Lines

At BESS (Battery Energy Storage Systems), we are committed to accelerating the global transition toward clean energy by providing cutting-edge solutions for battery production,

Get Started

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Explore challenges and solutions in streamlining lithium-ion battery pack processes for efficient, customized, and automated production.

Get Started

Lithium Battery Formation and Capacity Grading Cabinet

Oct 9, 2024 · China''s battery production capacity grew 56% year-over-year in 2023, reaching 1,200 GWh, with Tier 2 battery manufacturers accelerating automated formation line

Get Started

BATTERY CELL FORMATION TURNKEY

Sep 26, 2024 · The battery cell formation turnkey solution is applicable for full-automation and semi- automation production lines depending on the production mode and its capacity. The

Get Started

Lithium battery energy storage cabinet production tutorial

How to improve the production technology of lithium ion batteries? However, there are still key obstacles that must be overcome in order to further improve the production technology of LIBs,

Get Started

World-leading Lithium Battery Production Line Solutions

A full set of lithium battery producing equipment from mixing to last testing equipment,Including Manual lab line,semi-auto battery line and full auto battery production Line.

Get Started

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · Lithium-ion Battery Module and Pack Production Line Process Flow The lithium-ion battery module and pack production line is a complex

Get Started

Battery production equipment and services

Jun 14, 2024 · Battery excellence for all manufacturing processes The increasing demand for clean energy is driving substantial growth in the battery industry. The advanced technology

Get Started

Battery assembly solution

Aug 19, 2025 · JOT Automation''s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery

Get Started

Battery Production Line: The Powerhouse of

Feb 25, 2025 · A battery production line is a specialized manufacturing system designed to produce batteries efficiently and at scale. It involves a series of

Get Started

Tertron: Your Partner in Advanced Battery

Choose TERTRON''s automated battery production lines, featuring precision assembly, integrated quality control, and scalability for lithium-ion and other

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

Battery Pack Automated Assembly Production Line

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique

Get Started

Production Line Solution

Apr 25, 2025 · Solution for Secondary Battery Manufacturing Solution for Automotive Parts Manufacturing Core Technologies for Our Solutions Our Production Line Solution are based

Get Started

HuiYao Intel

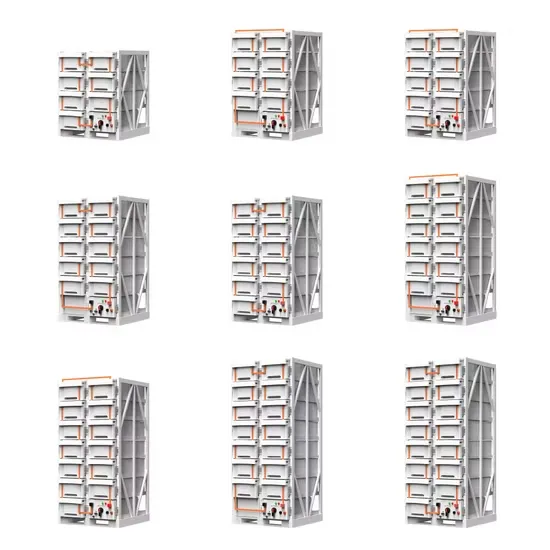

Our production line for prismatic battery modules stands out for its ability to meet the growing demands of the energy storage market. By prioritizing this sector, we aim to provide reliable

Get Started

Tertron: Your Partner in Advanced Battery

Tertron, a leading provider of Battery Production Line solutions, offers a range of advantages that set it apart in the industry. With its strong R&D capabilities,

Get Started

Battery production of the future | Bosch Rexroth

As a provider of automation solutions, Bosch Rexroth supports the entire value stream: From electrode and cell production to battery module and pack

Get Started

UPS Battery Cabinet Upgrade, Retrofit, Replacement

5 days ago · Whether leveraging an existing cabinet through a like-for-like replacement or opting for a new UPS battery cabinet or rack altogether, you''ll need to consider connector

Get Started

Automate battery production with robotics and proven solutions

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery

Get Started

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

Get Started

Battery assembly solution

Aug 19, 2025 · The JOT battery assembly solution is made for high-grade battery assembly for electric vehicle, energy storage and other battery manufacturers.

Get Started

Production Line Solution

Apr 25, 2025 · Our Production Line Solution are based on four core technologies. Roll press equipment is a technology for roll-to-roll press, which enables the pressing and processing of

Get Started

Home Pylontech Website, Pylon Technologies

Pylon Technologies Co.We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies

Get Started

LG Energy Solution''s $5.5 Billion Stand-Alone

Apr 4, 2024 · LG Energy Solution invites Arizona state government and local community officials for a construction progress update on its second U.S.

Get Started

Lithium Battery Module Pack Assembly Line

In the rapidly evolving electric vehicle (EV) and energy storage markets, the Lithium Battery Module Pack Assembly Line plays a pivotal role in ensuring high-efficiency, safety, and

Get Started

ESS Battery | LG Energy Solution

Through our world-renowned excellence in technology and mass production capability, we are leading the ESS market with a wide range of clients who

Get Started

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Get Started

BATTERY PRODUCTION OF THE FUTURE

Jan 2, 2025 · HIGH PERFORMANCE FOR YOUR PRODUCTION As a globally established provider of automation solutions, we support the entire value stream: From electrode and cell

Get Started

lithium-ion battery production lines

Aug 16, 2025 · We are developing, constructing and building customized manufacturing solutions for transportation battery and energy storage

Get Started

6 FAQs about [Battery cabinet production line technical solution]

Why should you choose our automated battery pack assembly line?

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique double-sided cross spot welding equipment for one-time welding, reducing costs and simplifying ope

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

What is a production line solution?

Our Production Line Solution are based on four core technologies. Roll press equipment is a technology for roll-to-roll press, which enables the pressing and processing of advanced materials with high precision into high density. High-speed, high-precision technologies are applied to electrode stacking devices and automatic assembly systems.

What is the Jot battery assembly solution?

Watch the JOT Battery Assembly Solution in action. JOT Automation’s industry-leading battery assembly solution is a fully complete, turnkey solution for battery assembly that is also EV battery compatible. Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing.

What is battery cell assembly?

battery cells is the cell assembly. We can supply you with our own machines for selected process steps as well as turnkey lines al ng with best-fit external equipment. All processes have been developed type buildBenefits of our solutionSmart factory planning is th

What are the assembly steps & requirements for high-quality battery systems?

We understand the individual assembly steps and requirements that are necessary for high-quality battery systems. cell preparation, cleaning, quality check, foil/pad application, tab cutting and bending, stacking, welding, bonding, gluing, filling, screwing, EOL, placing, screwing, gluing, filling, wiring, guided manual assembly, EOL,

Related Articles

-

Automatic lithium battery station cabinet production line

Automatic lithium battery station cabinet production line

-

Tripoli lithium battery station cabinet production line

Tripoli lithium battery station cabinet production line

-

Battery cabinet BMS production line

Battery cabinet BMS production line

-

Thailand energy storage cabinet battery production line

Thailand energy storage cabinet battery production line

-

San Marino outdoor communication battery cabinet photovoltaic production

San Marino outdoor communication battery cabinet photovoltaic production

-

Haiti Energy Storage Cabinet Battery Production

Haiti Energy Storage Cabinet Battery Production

-

Astana professional battery cabinet production

Astana professional battery cabinet production

-

Mozambique energy storage cabinet battery production

Mozambique energy storage cabinet battery production

-

UPS battery cabinet load-bearing frame production

UPS battery cabinet load-bearing frame production

-

How much is the battery cabinet production equipment price

How much is the battery cabinet production equipment price

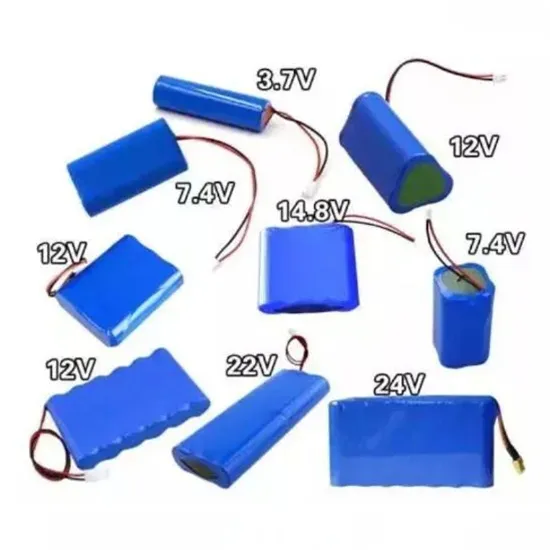

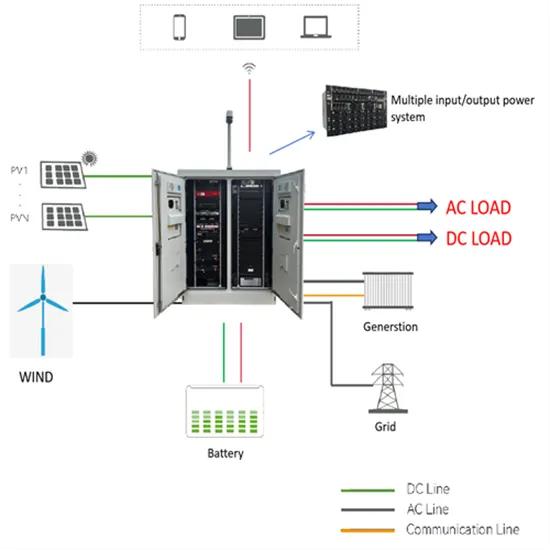

Commercial & Industrial Solar Storage Market Growth

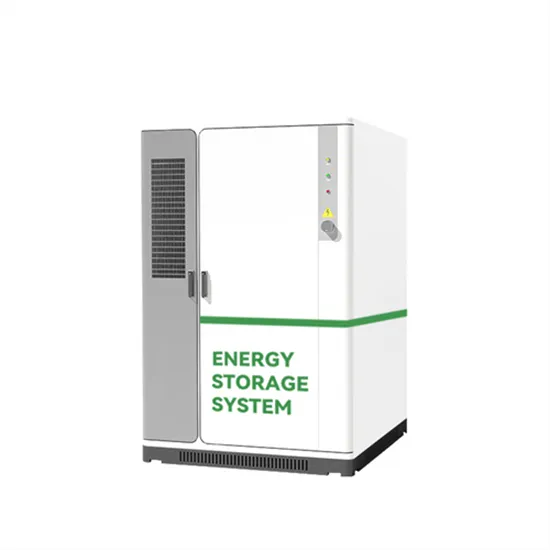

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.