Automatic Lithium Battery Production Line Battery Module

Jun 21, 2025 · Automatic Lithium Battery Production Line Battery Module Welding Machine, Find Details and Price about Battery Pack Welding Laser Welding Battery from Automatic Lithium

Get Started

Energy storage drawer cabinet assembly line

The energy storage drawer cabinet production line adopts double-speed chain conveying lines, roller conveying lines and AGVs (automatic guided transport vehicles) to reduce material

Get Started

Energy storage automatic assembly line

What is automatic lithium battery pack production line? 1. Introduction of Automatic Lithium Battery Pack Production Line An automatic lithium battery pack production line is a facility

Get Started

Cylindrical Lithium Battery Production Line

The production line for cylindrical lithium batteries is a complex and highly automated process designed to ensure high efficiency, quality, and

Get Started

Lithium-Ion Battery Assembly Line Process

Feb 25, 2025 · Explore the Lithium-Ion Battery Assembly Line —how precision, automation, and testing ensure high performance, safety, and reliability in

Get Started

Prismatic Lithium Battery Production Line Automatic

Mar 31, 2024 · Prismatic Lithium Battery Production Line Automatic, Find Details and Price about Battery Stacking Machine Car Battery Making Machine from Prismatic Lithium Battery

Get Started

Automate battery production with robotics and proven

Automation in battery production From the individual battery cell to the assembly of complete battery packs: With many years of expertise, KUKA covers the entire value chain in battery

Get Started

Lithium battery module pack assembly line production line

Oct 11, 2023 · At present, most battery pack assembly lines adopt semi-automatic and fully-automated production line. Considering the cost and construction site, SHINHOP assembly

Get Started

Prismatic Cell Fabrication Line

Sep 25, 2024 · Conclusion Automatic Prismatic Cell Production Line is integral to the production of advanced lithium-ion batteries that support a variety of

Get Started

Lithium Battery Module Pack Assembly Line

Our battery module and pack assembly lines are designed with flexibility and scalability in mind, supporting custom configurations for both small-batch prototyping and high-volume mass

Get Started

Lithium Ion Battery Pack Assembly Machine Automatic Lithium Ion Battery

Jul 4, 2025 · Lithium Ion Battery Pack Assembly Machine Automatic Lithium Ion Battery Production Line, Find Details and Price about Prismatic Battery Pack Assembly Line Lithium

Get Started

Optimizing Lithium-Ion Battery Pack Line

Oct 22, 2024 · Learn how to overcome challenges in lithium-ion battery pack assembly with automation, customization, and advanced process control for

Get Started

Automatic lithium battery packaging line

The automatic lithium battery packaging line provided by the invention has the advantages of high degree of automation, high precision, high efficiency and small occupied space.

Get Started

Tertron: Your Partner in Advanced Battery

Choose TERTRON''s automated battery production lines, featuring precision assembly, integrated quality control, and scalability for lithium-ion and other

Get Started

Assembly line for battery modules and battery packs

3 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Get Started

New Small Cylindrical Lithium Battery Packs Automatic Assembly Line

Shenzhen benice Technology Co., Ltd. is a national high-tech enterprise integrating R&D, manufacturing, sales and technical services. Founded in Shenzhen in 2010, it focuses on

Get Started

High

Jun 9, 2025 · High - Efficiency and Fully Automatic Lithium Battery Production Line, Find Details and Price about Lithium Battery Assembly Line from High - Efficiency and Fully Automatic

Get Started

Energy storage cabinet battery production line

The prismatic lithium battery production line is used to manufacture metal-cased prismatic lithium-ion batteries, primarily for electric vehicles and energy storage systems.

Get Started

AOOSER Automatic Assembly Line of Electric

As one of the representatives of China''s lithium battery intelligent equipment enterprises, AS Battery Technology has independently developed a semi

Get Started

Automatic Lithium Ion Battery Manufacturing Plant LiFePO4 Li

Find verified Automatic Lithium Ion Battery Manufacturing Plant LiFePO4 Li Ion Battery Production Line suppliers and manufacturers offering competitive wholesale prices. Browse detailed

Get Started

Semi-Automatic or Fully Automatic (Customized) Lithium Ion Battery

Aug 1, 2025 · Semi-Automatic or Fully Automatic (Customized) Lithium Ion Battery Module Pack Production Line with Good Efficiency, Find Details and Price about Production Line Assembly

Get Started

Lithium Battery PACK Production Line Processes

The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks,

Get Started

Automatic Lithium Battery Production Line

Aug 4, 2025 · Lithium battery module fully automatic assembly line is mainly used in the production of new energy lithium battery modules, Prismatic battery

Get Started

Efficient Battery Module Assembly Platform: Automated Lithium

Discover our state-of-the-art Battery Module Assembly Platform designed for efficient and precise lithium-ion battery module production. Suitable for manual, semi-automated, or fully automated

Get Started

AOOSER Automatic Assembly Line of Electric

Description: The production line mainly realizes the automatic production process of battery packs. The total length of the line is 16 meters, and the whole line is

Get Started

Turnkey lines for battery pack technologies

We offer modular and flexible solutions to cover many fields, such as energy storage systems of research and development machines, as well as complete

Get Started

Automatic Lithium Battery Pack Production Line Industrial

At the present stage, the assembly line has realized the whole process automation of charging, sorting, assembling, welding, testing and other links of the battery and module, with a stable

Get Started

BSLBATT Launches Fully Automated Lithium Battery Production Line

Aug 5, 2025 · BSLBATT announces its fully automated lithium battery production line, featuring high-speed laser welding and advanced battery module assembly. With a 60,000-unit annual

Get Started

lithium-ion battery production lines

Aug 16, 2025 · Our product portfolio covers module and pack assembly for lithium-ion or sodium-ion batteries. Check our lithium-ion battery production lines.

Get Started

Safety cabinets and fireproof battery cabinets for lithium batteries

Here you will find safety cabinets / fireproof battery cabinets for storing lithium batteries / Li-ion batteries. Can't find a suitable item? Contact us by e-mail (info@lion-care ), via the

Get Started

Battery Pack Manufacturing Machine,Battery

Product Introduction This customized production line is mainly used to complete the assembly, inspection, assembly, and welding functions of the prismatic cell

Get Started

Automatic Lithium Battery Assembly Line Explained

An Automatic Lithium Battery Assembly Line is an integrated, high-tech manufacturing system designed to automate the entire process of assembling Li-ion battery packs.

Get Started

Lithium Battery Production Line Auto Electrode

Jul 11, 2025 · Based on the factory, we can offer all services (Raw Materials, Equipments, Technology, etc. ) for full set of lithium battery producing line to

Get Started

Design of Control System of Automated Production Line

Mar 30, 2023 · There are countless research theories on the design of automated production line control systems based on PLC and robots. For example, Zhang Linfang has developed a PLC

Get Started

Düperthal BATTERY station line XL safety cabinet

The Düperthal BATTERY line station series includes various safety cabinets for lithium-ion rechargeable batteries / lithium-ion batteries. There are also 230 V

Get Started

Automatic Lithium Battery Module Pack

Jul 12, 2025 · This equipment is mainly used for automatic cutting and automatic lamination of electrodes of lithium-ion batteries. Including the following

Get Started

Related Articles

-

Tripoli lithium battery station cabinet production line

Tripoli lithium battery station cabinet production line

-

Battery cabinet end plate production line base station

Battery cabinet end plate production line base station

-

Labeling of battery cabinet automatic production line

Labeling of battery cabinet automatic production line

-

Sana outdoor lithium battery station cabinet design

Sana outdoor lithium battery station cabinet design

-

Somaliland lithium battery station cabinet customization company

Somaliland lithium battery station cabinet customization company

-

Costa Rica lithium battery station cabinet manufacturing

Costa Rica lithium battery station cabinet manufacturing

-

Outdoor lithium battery station cabinet design base station

Outdoor lithium battery station cabinet design base station

-

Lithium battery station cabinet base station energy price

Lithium battery station cabinet base station energy price

-

Which lithium iron phosphate battery station cabinet is better

Which lithium iron phosphate battery station cabinet is better

-

Battery cabinet BMS production line

Battery cabinet BMS production line

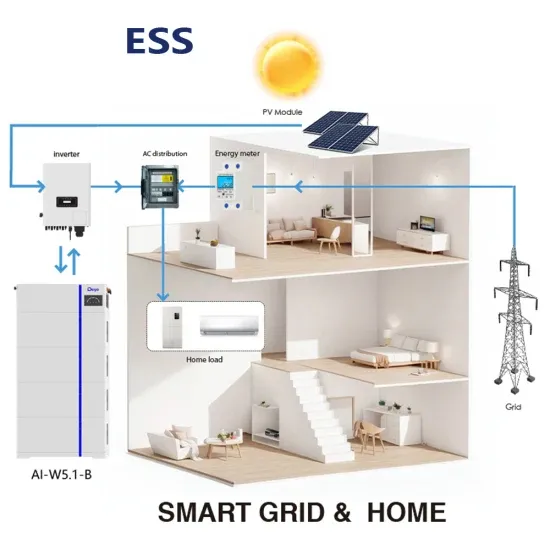

Commercial & Industrial Solar Storage Market Growth

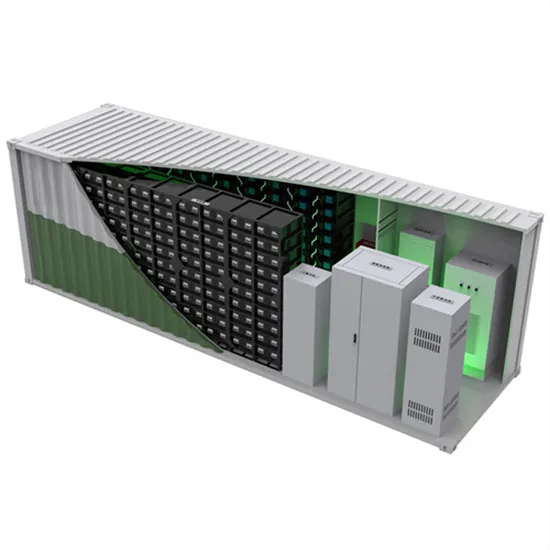

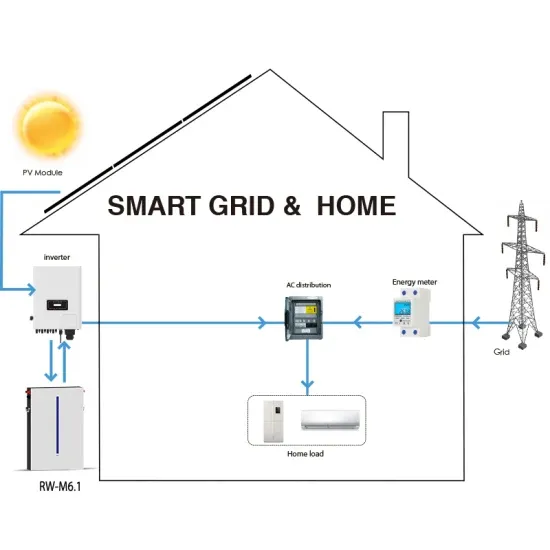

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

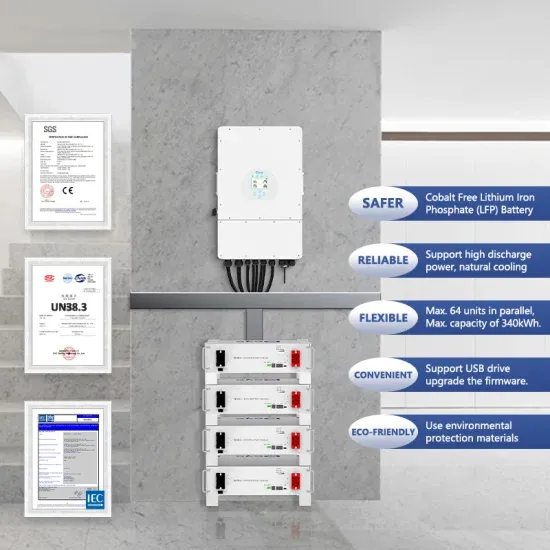

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.