Assembly line for battery modules and battery packs

4 days ago · For cell/module pack assembly, PIA Automation offers flexible and highly automated systems for the efficient production of battery cells, modules, and battery packs. These

Get Started

High-Performance Automatic Labeling Machine for Various

Discover the advanced Automatic Labeling Machine designed for efficient and precise labeling in various industries. Our machine features automatic label peeling, application, and smoothing,

Get Started

Automatic Labeling Production Line Drawing

Dec 17, 2024 · An Automatic Labeling Production Line Drawing is a technical illustration that outlines the layout and design of a comprehensive system

Get Started

Industrial Marking & Coding Options for

Jul 31, 2025 · When marking productions on a production line, there are 2 major solutions: labeling or printing. Each of these identification solutions offer

Get Started

Automatic Packaging Production Line

Jul 22, 2025 · The Automatic Packaging Production Line offers high-efficiency, customizable packaging, automated weighing, sealing, labeling, quality

Get Started

Automatic Single Side Labeling Machine For Battery

Aug 5, 2025 · Automatic single side labeling machine for battery our self-adhesive sticker labeling machine has its own unique single point like synchronized speed control system and flexible

Get Started

Design of cubic battery cabinet production line

analysis method for automatic production lines. Through analyzing the manual assembly process of battery cells and ree they could be improved from a cost standpoint. Chapter 8 descri

Get Started

Automatic Battery Cell Packaging Line

Automatic Battery Cell Packing Line integrates the whole process: battery feeding, testing, bundling, packaging, labeling and QR printing. High speed (40 cartons/minute), safe, flexible

Get Started

Woodworking Machinery Auto Feeding Labeling Cnc Two

Wood Router DrillingSide Router Labeling Machine Nesting Machine automatic grade Automatic voltage 220V/380V Capacity Labeling and Side Drilling Nesting CNC Router Weight (KG)

Get Started

1-9、ACB框架断路器自动化装配检测柔性生产线.cdr

Jun 21, 2023 · Leakage circuit breaker automatic assembly and testing flexible production line, Automatic assembly and testing flexible production line for disconnecting switch, Low-voltage

Get Started

High Efficiency Automatic Labeling and Nesting

Apr 25, 2025 · The automatic nesting cell is one of the intelligent nesting solutions in the automatic production line of panel furniture. This nesting cell consists of

Get Started

Automatic Label Applicators | Production Line

Increasing overall packaging line efficiency Saving costs on label application Automatic labelling delivers exceptional results for every production line, from

Get Started

CN105059641A

The invention provides a battery labeling apparatus, and belongs to the technical field of battery production. The battery labeling apparatus comprises: a conveyor belt for conveying a plurality

Get Started

Automatic labeler, Automatic labelling machine

Automatic labelers | Choosing the Right Labeler Automatic labelers generally have a stepper motor and allow labels and tags to be applied quickly and evenly. Due to their high production

Get Started

3 SIDE LABELING MACHINE IN PRODUCTION LINE

Automatic labels are a best solution for investors. The 3-sided labeling machine is used for the food industry such as bottled products or for the consumer industry such as washing liquid,

Get Started

Automatic Battery Production Line

These machines are designed to automate the labeling process, ensuring precise placement and adherence of labels onto batteries. These machines often

Get Started

Automated Assembly Line for EV CMC of Batteries

Built in a joint collaboration between Controlar and EIIT – a Controlar company, this fully automated testing line boasts a remarkable 13-second cycle time, ensuring swift and accurate

Get Started

Intelligent factory furniture production line

Apr 25, 2025 · The best line solution for cabinets and cabinet doors for bathroom, kitchen, office or home furniture. With no skilled workers needed online, it

Get Started

Understanding Automated Production Lines and

May 8, 2025 · Discover efficiency: Automated production lines streamline manufacturing with precision, reducing labor while maximizing output and quality.

Get Started

Automatic labeling device for square battery

The utility model belongs to the technical field of the battery, concretely relates to automatic labelling device of square battery, including conveying mechanism, positioning mechanism,

Get Started

Production Line Guide | CHISAGE Battery Pack

Sep 14, 2023 · The production process for Chisage ESS Battery Packs consists of eight main steps: cell sorting, module stacking, code pasting and scanning,

Get Started

Battery Labeling Machine – High-Quality

Feb 6, 2025 · The Battery Labeling Machine is an innovative solution designed to automate the process of labeling batteries efficiently and accurately. It is

Get Started

Automatic Labeling Machine | MPERIA Series

The A-Series labeling machine provides consistent, exact label placement with configurations for virtually any application. Multiple applicators address the

Get Started

Lithium-ion Battery Module and Pack Production

Apr 12, 2024 · The lithium-ion battery module and pack production line is a complex system consisting of multiple major units and associated equipment

Get Started

Automatic battery labeling line

Find a solution that sticks with labeling machines. Alibaba is the place to look for wholesale industrial, retail, office, and home automatic battery labeling line solutions.

Get Started

Automatic Maintenance Free Lead Acid Battery Terminal

Find verified Automatic Maintenance Free Lead Acid Battery Terminal Capping and Labeling Machine suppliers and manufacturers offering competitive wholesale prices. Browse detailed

Get Started

Automatic Labeling Machine: Enhance Product Identification

Labeling and Marking Machines are devices used to print and apply various identification information on battery modules, including barcodes, QR codes, serial numbers, production

Get Started

18650 Battery Pack Production Automatic

Jul 30, 2025 · 1 . Stickers pasted stable, consistent, and long lasting. 2. Automatic failure alarm. 3. Easy to program, adjust, and opertate for new hands. 4. High

Get Started

Automatic production line, Automatic making machine

Find your automatic production line easily amongst the 505 products from the leading brands (Farley Laserlab, Jwell, Vemag,) on DirectIndustry, the industry specialist for your

Get Started

Horizontal Wrap-around,Battery

Jul 1, 2025 · A204 is an ideal and economical solution for battery industry to labeling on the No.5 & No.7 batteries. Automatic downloading device and

Get Started

The best labeling machines for automatic labeling

Jul 7, 2021 · Modern labeling systems are automation solutions that can optimize any production line. Integrating an automatic labeling system offers many

Get Started

Battery automatic testing equipment production line

High precision, integrated battery cycling and energy storage test solutions designed for lithium ion and other battery chemistries. From R& D to end of line, we provide advanced battery test

Get Started

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

Get Started

Optimize Battery Assembly Line with Design and

5 days ago · A battery assembly line is a system that puts together different parts of a battery, like cells, tabs and modules, into a complete unit. It uses machines, robots and automation to

Get Started

Automated Assembly Line for Large and Small

2:Introduction: This production line is mainly used for the back-end application process of 32135/40140 cylindrical lithium batteries. Key processes include

Get Started

Related Articles

-

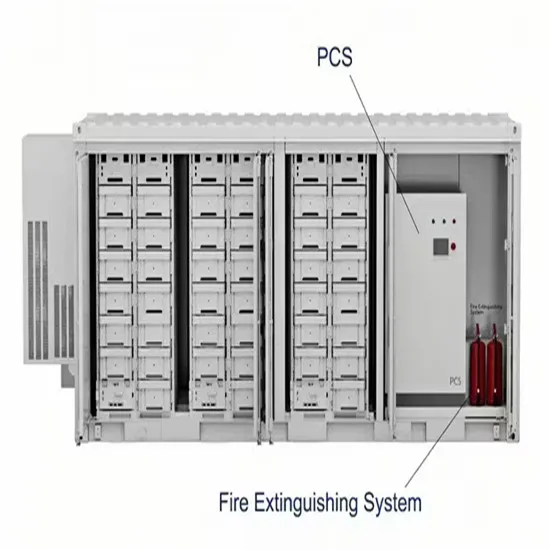

Automatic lithium battery station cabinet production line

Automatic lithium battery station cabinet production line

-

Battery cabinet end plate production line base station

Battery cabinet end plate production line base station

-

Battery cabinet BMS production line

Battery cabinet BMS production line

-

How much does a battery cabinet production line cost per day

How much does a battery cabinet production line cost per day

-

Thailand energy storage cabinet battery production line

Thailand energy storage cabinet battery production line

-

Battery cabinet automatic battery charging

Battery cabinet automatic battery charging

-

US Outdoor Site Battery Cabinet Production

US Outdoor Site Battery Cabinet Production

-

San Marino outdoor communication battery cabinet photovoltaic production

San Marino outdoor communication battery cabinet photovoltaic production

-

New energy battery cabinet automatic tightening

New energy battery cabinet automatic tightening

-

Battery cabinet automatic fire extinguishing system base station

Battery cabinet automatic fire extinguishing system base station

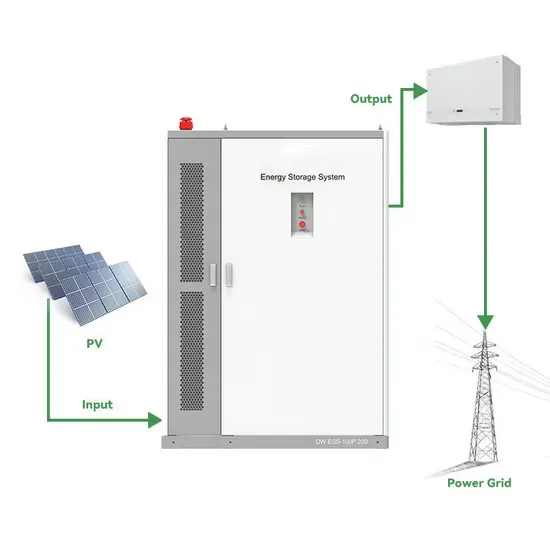

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

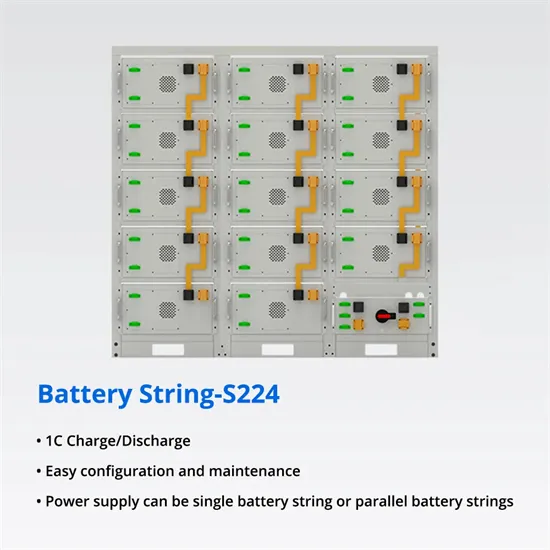

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.