Battery cabinet production cost accounting

ction and the standard cost of production. Standard costs are costs that should have been incurred to pro osures and take care of your unique needs. Our quality custom lithium-ion

Get Started

What Are the 9 Operating Costs of Lithium Ion

Jul 24, 2025 · Operating a lithium ion battery manufacturing facility like PowerPulse Energy Solutions involves detailed planning around several key

Get Started

Cost modeling for the GWh-scale production of modern

Nov 3, 2024 · Battery production cost models are critical for evaluating cost competitiveness but frequently lack transparency and standardization. A bottom-up approach for calculating the full

Get Started

What are the main cost components of utility-scale battery

Nov 19, 2024 · – Batteries typically last 10-20 years; replacement costs can be substantial and range between $5 million to $15 million for a 50MW/50MWh system depending on future

Get Started

What Are the 9 Operating Costs of Battery Manufacturing

Jul 24, 2025 · In battery manufacturing, skilled labor costs might be reflected in salaries ranging from $70,000 to $120,000 per year for each expert, depending on regional market conditions

Get Started

What Are the 9 Startup Costs for Battery Manufacturing in

Jul 24, 2025 · How Much Does It Cost To Start Battery Manufacturing For Electric Vehicles? Starting an EV battery manufacturing business, such as VoltCraft Innovations, requires careful

Get Started

A Techno-Economic Model for Benchmarking

Thus, developing a cost model that simultaneously includes the physical and chemical characteristics of battery cells, commodities prices, process

Get Started

Cost Of Lithium-ion Battery Manufacturing Plant & Machinery

An Introduction Lithium-ion batteries have become the most critical applications of lithium and storage technology in the fields of portable and mobile applications (such as laptops, cell

Get Started

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

Get Started

What Are the 2025 Startup Costs for Lithium Ion Battery

Jul 24, 2025 · How Much Do Lithium Ion Battery Manufacturing Owners Typically Earn? Earnings for lithium ion battery manufacturing owners can vary widely depending on several factors,

Get Started

How much does the energy storage battery

Jan 22, 2024 · The price of energy storage battery cabinets can vary significantly depending on various factors. 1. General cost range: The costs typically range

Get Started

Cost of solid state batteries: Expensive premium

Dec 22, 2022 · For the ramp-up phase of solid-state batteries, there is also already a forecast of costs: in a study conducted in 2019, CISION PR

Get Started

How Much Does It Cost To Buy a Cabinet Production Line?

Jun 7, 2024 · Cabinet production lines are widely used in the furniture industry, and with the advancement of technology and industrial upgrading, their application will be more in-depth

Get Started

Grid-scale battery costs: $/kW or $/kWh?

Nov 18, 2023 · Grid-scale battery costs can be measured in $/kW or $/kWh terms. Thinking in kW terms is more helpful for modelling grid resiliency. A good rule

Get Started

Behind the numbers: BNEF finds 40% year-on

Feb 5, 2025 · Ultimately, as previously mentioned, cost reductions are coming from multiple angles, from materials and battery costs to increased

Get Started

The Real Cost of Commercial Battery Energy

Apr 21, 2025 · In 2025, the typical cost of a commercial lithium battery energy storage system, which includes the battery, battery management system

Get Started

What are the main cost components of utility-scale battery

Nov 19, 2024 · Overall, utility-scale battery storage costs are a composite of energy capacity-related costs (battery cells, BOS energy components) denoted mostly in $/kWh, power

Get Started

Battery Manufacturing Plant Project Report: Unit Setup, Cost

Jul 17, 2025 · Key Cost Components of Setting Up a Battery Plant: · Land and Infrastructure: Costs for land acquisition, building construction, utilities, and facility layout.

Get Started

How much does a small battery energy storage cabinet cost?

Apr 16, 2024 · 1. Understanding the Cost of a Small Battery Energy Storage Cabinet 1.1. The cost of a small battery energy storage cabinet typically ranges from $5,000 to $15,

Get Started

Battery Cost Calculator | True Cost Of Powering

Mar 17, 2025 · Battery Cost Calculator serves as an essential tool for estimating the total cost associated with battery operations.

Get Started

Cost Projections for Utility-Scale Battery Storage: 2023

Jul 25, 2023 · The suite of publications demonstrates wide variation in projected cost reductions for battery storage over time. Figure ES-1 shows the suite of projected cost reductions (on a

Get Started

What Are the 9 Operating Costs in Electric

Jul 24, 2025 · These layered costs form the complete picture of battery production cost analysis, essential for understanding the comprehensive EV battery

Get Started

How much does it cost to build a battery energy

How much does it cost to build a battery in 2024? Modo Energy''s industry survey reveals key Capex, O&M, and connection cost benchmarks for BESS projects.

Get Started

Cost comparison of producing high-performance Li-ion batteries

Jun 1, 2013 · A comparison of the costs of battery cell production in the United States and in China indicates that highly automated production processes can make U.S.-based advanced

Get Started

Lithium Ion Battery Manufacturing: Cost

Jul 12, 2025 · Ever wondered about the Lithium Ion Battery Manufacturing Cost when launching your battery factory? Do fixed costs, raw material prices, and

Get Started

Battery Cost Per Kwh Chart | Battery Tools

How much does a battery cost per kilowatt? The cost of a battery per kilowatt-hour can vary widely depending on the type of battery, its capacity, and the

Get Started

Prices of Lithium Batteries: A Comprehensive Analysis

Apr 11, 2025 · Lithium battery prices fluctuate due to raw material costs (e.g., lithium, cobalt), manufacturing innovations, geopolitical factors, and demand surges from EVs and renewable

Get Started

How To Estimate The Costs To Start A Lithium

Apr 17, 2025 · How Much Does It Cost To Start Lithium Ion Battery Manufacturing? Launching a lithium ion battery factory demands rigorous

Get Started

Demystifying Energy Storage Cabinet Production Costs in 2024

But these unsung heroes of the renewable energy revolution quietly power our transition to cleaner grids. The production costs for these industrial-scale battery systems typically range

Get Started

What Are the 9 Startup Costs for EV Battery Manufacturing?

Jul 24, 2025 · How Much Does It Cost To Start EV Battery Manufacturing Company? Starting an EV battery manufacturing company like VoltDrive Innovations involves a detailed cost

Get Started

How much does the tower energy storage battery cabinet cost

Aug 16, 2024 · While purchasing tower energy storage battery cabinets may involve substantial initial costs, the long-term economic benefits often outweigh these investments.

Get Started

6 FAQs about [How much does a battery cabinet production line cost per day ]

How much does a battery production line cost?

Modern battery production lines require $10 million to $50 million in advanced machinery, essential for maintaining high throughput and efficiency in lithium-ion battery production. The cost of research and development for innovative battery solutions is another crucial factor.

How to start a lithium ion battery manufacturing business?

Starting a lithium ion battery manufacturing business requires a comprehensive understanding of the costs involved. From raw materials to labor, each component contributes to the overall manufacturing expenses. It’s essential to evaluate these costs meticulously to ensure profitability and sustainability in the competitive battery market.

How much does a battery startup cost?

Statistically, startups in this industry can expect to invest anywhere from $1 million to $5 million initially. This includes costs for machinery, raw materials, and facility setup. Additionally, you must account for costs related to research and development, as innovation is key to staying competitive in the battery market.

Is lithium ion battery manufacturing a good investment?

This surge presents an incredible opportunity for entrepreneurs looking to dive into the battery manufacturing industry. Lithium Ion Battery Manufacturing Costs can be a significant barrier to entry, but understanding these costs can set you on the right path to success.

What does a battery manufacturing facility renovation & customization entail?

The renovation and customization of the facility involve not only updating existing structures but also integrating advanced safety measures and equipment placement layouts to optimize battery manufacturing cost efficiency.

How much does it cost to replace a battery?

Batteries typically last 10-20 years; replacement costs can be substantial and range between $5 million to $15 million for a 50MW/50MWh system depending on future battery prices. – Other components like power converters and cooling systems may also require replacement, adding 20-30% extra replacement costs.

Related Articles

-

Battery cabinet BMS production line

Battery cabinet BMS production line

-

How much does it cost to be an agent for a site energy battery cabinet

How much does it cost to be an agent for a site energy battery cabinet

-

How much does a Bangi outdoor communication battery cabinet cost

How much does a Bangi outdoor communication battery cabinet cost

-

How much is the battery cabinet production equipment price

How much is the battery cabinet production equipment price

-

How much does it cost to replace the battery in Bandar Seri Begawan s outdoor communication battery cabinet

How much does it cost to replace the battery in Bandar Seri Begawan s outdoor communication battery cabinet

-

How to make battery cabinet production equipment

How to make battery cabinet production equipment

-

How much does it cost to replace a lithium battery station cabinet in Kuwait City

How much does it cost to replace a lithium battery station cabinet in Kuwait City

-

Tripoli lithium battery station cabinet production line

Tripoli lithium battery station cabinet production line

-

How much does it cost to replace a battery cabinet in Papua New Guinea

How much does it cost to replace a battery cabinet in Papua New Guinea

-

How much does a small battery energy storage cabinet cost

How much does a small battery energy storage cabinet cost

Commercial & Industrial Solar Storage Market Growth

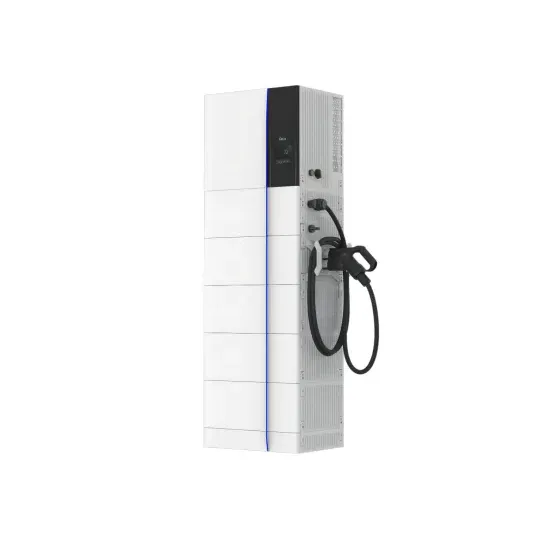

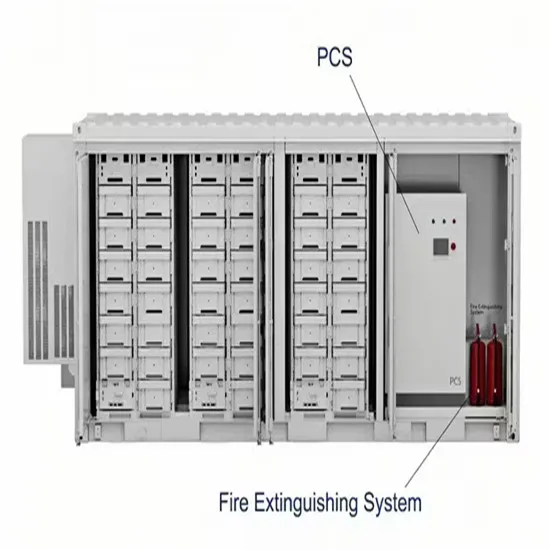

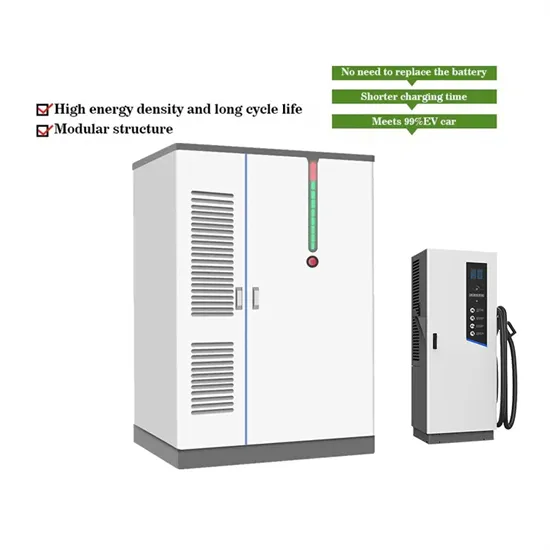

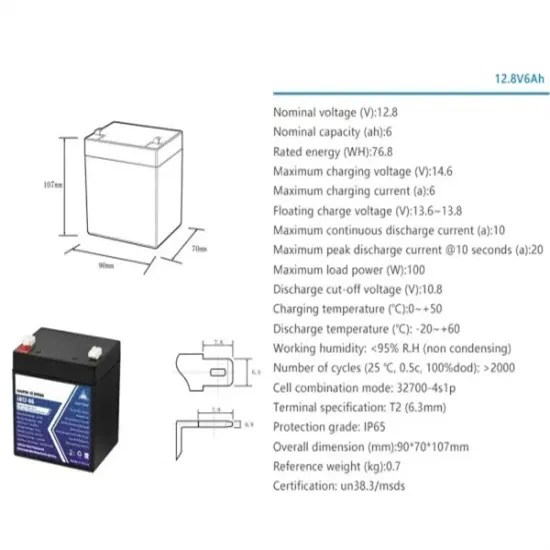

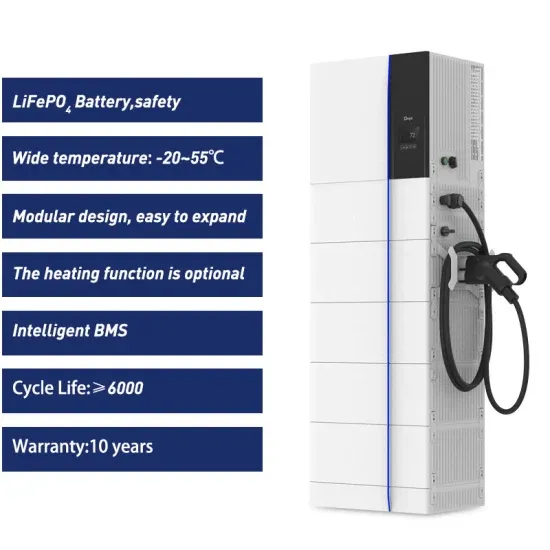

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.