Recycling paths for thin-film chalcogenide photovoltaic waste – Current

Jul 1, 2013 · Thin film chalcogenide photovoltaic technologies (CIGS, CdTe) make use of critical and toxic materials. Therefore a sound recycling of production waste and of end-of-life PV

Get Started

(PDF) Recycling paths for thin-film chalcogenide

Thin film chalcogenide photovoltaic technologies (CIGS, CdTe) make use of critical and toxic materials. Therefore a sound recycling of production waste

Get Started

A Review of Recycling Processes for Photovoltaic

Feb 15, 2018 · This review presents a summary of possible PV recycling processes for solar modules, including c-Si and thin-film technologies as well

Get Started

Photovoltaic module recycling, a physical and a chemical

May 1, 2019 · For these reasons, photovoltaic modules have to be treated before landfilling as required by the legislation. The subject of this paper is the polycrystalline silicon type

Get Started

Recovery and analysis of polymeric layers from waste solar modules

Sep 15, 2022 · The crystalline silicon solar panels dominate the photovoltaic market and it employs various valued materials like glass, aluminium, silver, silicon, copper, and polymeric

Get Started

A novel approach for the recycling of thin film photovoltaic modules

Aug 1, 2010 · The RESOLVED project aims to demonstrate sustainable recycling strategies for photovoltaic thin film modules based on (wet-) mechanical processes to reduce the amount of

Get Started

Review of c-Si PV module recycling and

Jan 21, 2025 · Abstract As solar energy emerges as a pivotal renewable energy source, the environmental challenge of end-of-life photovoltaic (PV) module

Get Started

Technology and Climate Trends in PV Module Degradation

Oct 3, 2013 · Thin-film technologies are characterized by a much higher contribution from fill factor particularly for humid climates. Crystalline Si technologies in hot & humid climates also display

Get Started

Managing photovoltaic Waste: Sustainable solutions and

Nov 15, 2024 · It uses material composition data to estimate waste flow, converting installed capacity into waste based on a 25-year module lifespan and projecting future waste volumes

Get Started

Thin Film Photovoltaics

Oct 7, 2013 · Since sunlight carries relatively little energy in comparison with combustion-based energy sources, photovoltaic (PV) modules must be cheap to produce energy that can be

Get Started

(PDF) Recovery of Valuable Materials and

Dec 17, 2021 · Due to the development of new photovoltaic technologies, there is a need to research new recycling methods for these new materials. The

Get Started

Review on recycling of solar modules/panels

May 1, 2023 · A review article on recycling of solar PV modules, with more than 971GWdc of PV modules installed globally by the end of 2021 which includes already c

Get Started

A review on energy conversion using hybrid photovoltaic

Apr 1, 2023 · This review focuses on the principles of solar cell and thermoelectric device, and emphasizes the key components and techniques. It summarized not only the updated

Get Started

Progress in Thin-Film Photovoltaics: A Review of

Mar 20, 2025 · Thin-film solar cells (TFSCs) represent a promising frontier in renewable energy technologies due to their potential for cost reduction,

Get Started

Delamination of components for recovery of waste

Jan 15, 2025 · Therefore, recovery of waste photovoltaic panels is a meaning work from the aspects of circular economy and sustainable development of photovoltaic industry. A critical

Get Started

Evaluation of the environmental benefits of new high value

Jul 15, 2013 · Abstract This paper presents the preliminary results of an environmental evaluation carried out by the application of Life Cycle Analysis (LCA), to a new method proposed for

Get Started

Waste heat harvesting from thin-film solid oxide fuel cells via

A thin-film solid oxide fuel cell (TF-SOFC) is an electrochemical device that generates electricity at medium temperatures through redox reactions between fuel (e.g., hydrogen or hydrocarbons)

Get Started

What is Thin Film Photovoltaic Module?

Nov 17, 2023 · What is Thin Film Photovoltaic Module consist of layers containing amorphous silicon, cadmium telluride, or copper indium gallium selenide.

Get Started

CdTe photovoltaic technology: An overview of waste

Jun 1, 2024 · CdTe panel is a leader among thin-film technologies for solar panels and, according to some studies, promises the lowest production cost compared with other PV technology

Get Started

Recovery of Valuable Materials and Methods for

Modules based on crystalline silicon and modules made with thin-film technologies must be recycled in three stages: delamination, material

Get Started

A novel approach for the recycling of thin film photovoltaic modules

The paper presents the development of two strategies for thin film PV recycling based on (wet) mechanical processing for broken modules, and combined thermal and mechanical methods

Get Started

Review on recycling of solar modules/panels

May 1, 2023 · While the recycling of waste PV modules has already begun to be commercialized, various technologies for PV module recycling are under development in order to improve

Get Started

Investigational evaluation of a thin film photovoltaic module

Jan 1, 2021 · The decrease in temperature affects the power output of the photovoltaic module and the average power yield drops down very sharply. In the present study, the experimental

Get Started

Thin-Film Solar Panels: An In-Depth Guide

Mar 12, 2022 · In 1980, researchers finally achieved a 10% efficiency, and by 1986 ARCO Solar released the G-4000, the first commercial thin-film solar

Get Started

Solar photovoltaic recycling strategies

Mar 1, 2024 · Apart from the modules reaching their functional lifetime, other damaged modules caused by the manufacturing, transportation and installation process, and those with

Get Started

Photovoltaic Module Waste and the Circular Economy: A

Apr 12, 2025 · With an average 25-year life cycle for photovoltaic modules (PVm), few attentions are placed on the problem associated with the generation of waste, actors such as the lack of

Get Started

Photovoltaic Panels End-of-Life Recycling | SpringerLink

Apr 1, 2023 · In short, the number of photovoltaic panels reaching the end-of-life (EoL) stage would increase exponentially as the number of photovoltaic installations increases. At the end

Get Started

Comprehensive review in waste heat recovery in different

Jun 1, 2022 · This paper presents a comprehensive review of recent studies in electrical power generation from various thermal-consuming processes. In particular, the paper concentrates

Get Started

Thin-Film Photovoltaic Partnership -

Aug 9, 2013 · The downstream processes involved in the manufacture of Apollo® thin film modules generate waste streams contaminated with organic material and cadmium. These

Get Started

Recycling of waste crystalline silicon photovoltaic modules:

This study combines the wet decapsulation of photovoltaic modules with the Ag extraction of solar cells. The eco-friendly reagents adopted provide new guidance for the recycling of waste

Get Started

Projection of Waste Photovoltaic Modules in China

Sep 1, 2022 · China''s rapid deployment of photovoltaic (PV) generation will result in large volumes of waste photovoltaic modules. Predictions about future waste modules flows are a crucial step

Get Started

Methodological approaches for resource recovery from end

Jan 1, 2025 · Substantial recoveries of critical from obsolete thin-film panels are notable with the application of mechanical and hydrometallurgical waste treatment techniques. Third

Get Started

Integrated thinking for photovoltaics in buildings

Jun 8, 2018 · Recent developments in photovoltaic technologies enable stimulating architectural integration into building façades and rooftops. Upcoming policies and a better coordination of

Get Started

Flash separation and recovery of each component from waste photovoltaic

Jun 1, 2025 · As a result, emissions of fluorine-containing waste are reduced, and the recycling of organic plastic waste is facilitated. The recovery ratio of valuable components from EoL

Get Started

6 FAQs about [Waste heat from thin-film photovoltaic modules]

Is there a thin-film photovoltaic recycling process?

The Colorado School of Mines developed a recycling process for PrimeStar Solar's CdTe PV modules , . Besides those processes designed for commercialization, thin-film photovoltaic recycling was investigated in several research and demonstration projects in the United States of America, Japan and Europe.

Can thin-film chalcogenide photovoltaic waste be recycled?

Recycling of solar Thin Film PV modules and scraps, and closed-loop use of metals. Innovation Forum for Life-Cycle Strategies and Recycling of Scarce Metals of Strategic Importance; 2011 64. Marwede M, Berger W, Schlummer M, Mäurer A, Reller A. Recycling paths for thin-film chalcogenide photovoltaic waste–Current feasible processes.

How are thin-film solar modules recycled?

Thin-film solar modules recycling processes. The large-scale recycling of thin-film PV modules is well advanced and, as well as the Si solar cells, thin-film PV modules are currently processed and recycled using a combination of mechanical and chemical treatments to achieve meaningful outcomes.

Are PV thin film modules recyclable?

Already in the 1990s first recycling strategies for PV thin film modules were being developed ( Bohland et al., 1997, Bruton et al., 1994, Eberspacher et al., 1994, Fthenakis et al., 1996, Menezes, 1996, Wambach, 1998 ).

What is a photovoltaic recycling program?

In July 2007, the photovoltaic industry founded the PV Cycle Association in Brussels, whose purpose is the creation of a voluntary industry-wide take-back and recycling program for end-of-life modules in Europe ( PV Cycle, 2008 ). 3. Materials Within the RESOLVED project the recycling of thin film modules was performed using CdTe and CIS modules.

Why do we need a sustainable recycling of photovoltaic modules?

The rapid development and growth of the photovoltaic market and the estimated quantities of photovoltaic waste in the near future, as well as the scarcity of semiconductor materials, demand a sustainable recycling of PV modules.

Related Articles

-

Disadvantages of photovoltaic thin-film modules

Disadvantages of photovoltaic thin-film modules

-

Do photovoltaic modules use lithium batteries

Do photovoltaic modules use lithium batteries

-

Prices of photovoltaic modules in Aarhus Denmark

Prices of photovoltaic modules in Aarhus Denmark

-

Huawei polycrystalline silicon double glass photovoltaic modules

Huawei polycrystalline silicon double glass photovoltaic modules

-

Danish thin film photovoltaic modules

Danish thin film photovoltaic modules

-

Project site lightweight photovoltaic modules

Project site lightweight photovoltaic modules

-

Price changes of photovoltaic modules

Price changes of photovoltaic modules

-

What does vpm mean in photovoltaic cell modules

What does vpm mean in photovoltaic cell modules

-

Brunei photovoltaic modules single wave and dual wave

Brunei photovoltaic modules single wave and dual wave

-

Photovoltaic modules exported from Montenegro

Photovoltaic modules exported from Montenegro

Commercial & Industrial Solar Storage Market Growth

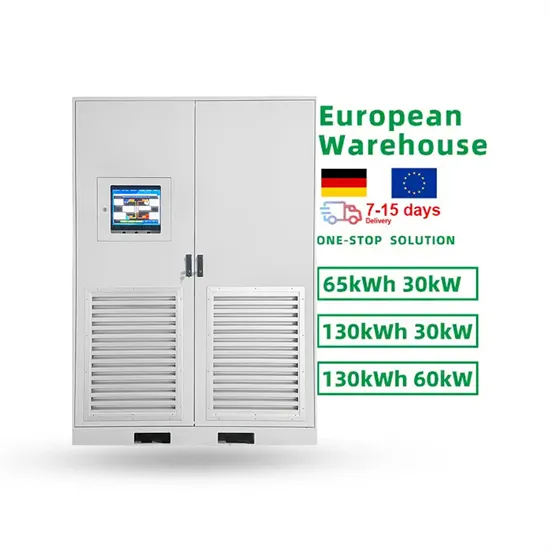

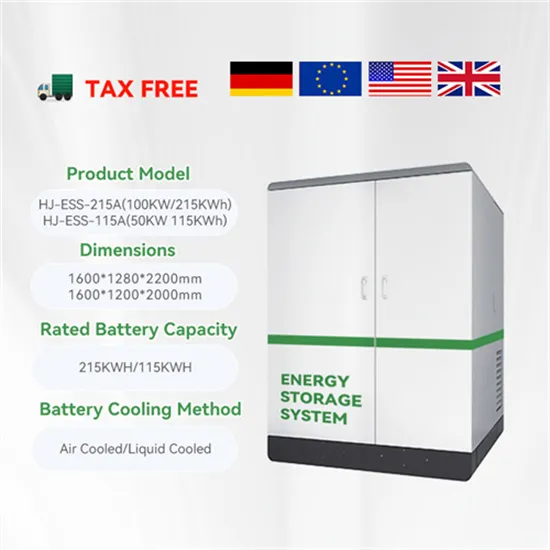

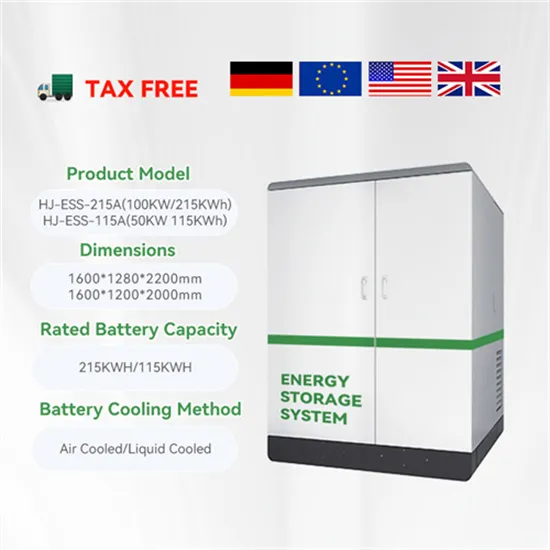

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

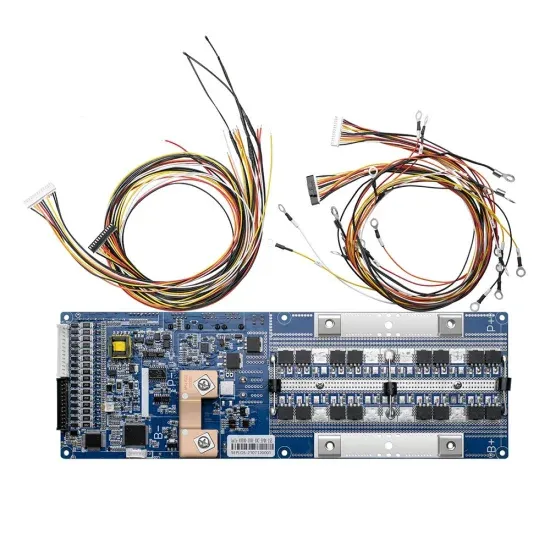

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.