Thin Films Photovoltaics

Oct 8, 2023 · Thin film photovoltaic-based solar modules produce power at a low cost per wat. They are ideal candidates for large-scale solar farms as well as building-integrated

Get Started

Thin Film Photovoltaics

Jan 1, 2018 · Thin film solar cell technology has recently seen some radical advancement as a result of new materials and innovations in device structures. The increase in the efficiency of

Get Started

Thin Film Photovoltaics

Thin film photovoltaic modules also benefit from a relatively small drop in power output under partial shadowing when compared with crystalline silicon photovoltaics. This gives thin film

Get Started

Inventions, innovations, and new technologies: Flexible and

Sep 1, 2023 · We review recent inventions and innovations to enhance the distinctive properties and functionalities of thin-film devices for successfully adapting in the emerging applications.

Get Started

New method can reduce thermal degradation of

Nov 10, 2024 · Current photovoltaic (PV) panels typically contain interconnected solar cells that are vacuum laminated with a polymer encapsulant between

Get Started

Microsoft Word

Jul 29, 2024 · a. a-Si-thin-film photovoltaic sample, b. a-Si-thin-film PV laminated into two fully flexible, yet not laminated sheets of ETFE-foil, still fully flexible

Get Started

Thin Films Photovoltaics

Feb 23, 2022 · Thin film photovoltaic-based solar modules produce power at a low cost per watt. They are ideal candidates for large-scale solar farms as well

Get Started

Thin-Film Solar Cells: Definition, Types & Costs

Jul 22, 2024 · The main difference between thin-film solar panels and other types, such as monocrystalline and polycrystalline, lies in their material composition

Get Started

Sep 16, 2020 · Partially transparent solar panels contain extremely thin slivers of crystalline (or thin-film) silicon photovoltaic (PV) material encased between layers of glass.

Get Started

Solar Photovoltaic Glass: Classification and Applications

Jun 26, 2024 · Depending on their properties and manufacturing methods, photovoltaic glass can be categorized into three main types: cover plates for flat-panel solar cells, usually made of

Get Started

Thin-film Solar Overview | Cost, types, application, efficiency

Aug 25, 2019 · Rigid thin-film cells have other commercial applications (inserting or interleaving between two panes of glass) in some of the largest photovoltaic power stations in the world.

Get Started

Thin Film Solar Panels

Dec 5, 2022 · In the second generation of crystalline silicon (c-Si) panels, thin film solar cells are created by depositing one or more layers of thin photovoltaic

Get Started

Solar Glass: applications and comparison to Light-Trapping

Solar Glass is one of the crucial barriers of traditional solar panels protecting solar cells against harmful external factors, such as water, vapor, and dirt. For what type of solar panels is glass

Get Started

From Sunlight to Energy: How Power-Generating Glass is

Mar 30, 2023 · According to Liu Shixu, the dean of the Smart Energy Research Institute of Chuan Kai Electric Co., Ltd., the park has installed 6,880 pieces of power generation glass that are

Get Started

Thin Films Photovoltaics

Oct 8, 2023 · They are ideal candidates for large-scale solar farms as well as building-integrated photovoltaic applications. They can generate consistent power, not only at elevated

Get Started

Microsoft Word

The technology even has the potential of reaching lower system costs than thin-film Si on glass. Also the energy pay-back time is relatively short (about 1.2 years for conventional modules

Get Started

Towards very low-cost mass production of thin-film silicon photovoltaic

Apr 28, 2006 · One of the obstacles is given by the present high production costs of PV modules. A possibility to reduce costs are thin-film PV modules on glass. The specific option of thin-film

Get Started

Thin-Film Solar Panels: How They Work, Pros

Sep 18, 2023 · Thin-film solar panels are photovoltaic solar panels made from thin layers of semiconductor materials deposited on a low-cost substrate, like glass

Get Started

What are thin-film solar cells? description, and types

Sep 26, 2019 · Thin-film solar cells are the second generation of solar cells. These cells are built by depositing one or more thin layers or thin film (TF) of photovoltaic material on a substrate,

Get Started

Reducing Thermal Degradation of Perovskite Solar Cells

Nov 7, 2024 · Current photovoltaic (PV) panels typically contain interconnected solar cells that are vacuum laminated with a polymer encapsulant between two pieces of glass or glass with a

Get Started

Transmittance improvement and photocatalyst performance

Apr 24, 2025 · The transmittance and surface condition of photovoltaic cover glass determine the energy conversion efficiency of specific solar cells modulus. In this study, TiO2-SiO2 based

Get Started

Front glass crack inspection of thin-film solar photovoltaic

May 15, 2024 · Thin film solar modules have gained attraction due to their unique advantages over traditional crystalline modules. Thin film technology utilizes various materials, such as

Get Started

A Comprehensive Guide to Thin Film Solar

Mar 14, 2024 · Thin film solar panels are a type of solar technology that uses thin layers of photovoltaic materials to convert sunlight into electricity. Unlike

Get Started

Challenges and Perspectives of Thin-Film Photovoltaics

Mar 6, 2023 · Thin-film solar cells provide new options for PV applications, e.g., semi transparency for building integration or roll-to-roll production of light-weight and flexible

Get Started

Amorphous Photovoltaic Panels: Flexible & Efficient Solar

Need bendable solar panels? Amorphous photovoltaic panels offer lightweight efficiency for curved surfaces and BIPV installations. Discover top-rated options with transparent designs

Get Started

Revolutionizing Thin-Film Photovoltaics:

Apr 29, 2025 · Thin film photovoltaics (PV) currently comprises a small portion of the total solar market, yet offer extensive opportunities for applying solar

Get Started

Long-term photovoltaic performance of thin-film solar

Nov 17, 2023 · Over the last decade, perovskite solar cells (PSCs) have developed rapidly with higher power conversion efficiencies (PCEs) and lower costs. It has been reported that the

Get Started

Thin-Film Solar Photovoltaics: Trends and Future Directions

Dec 5, 2024 · Thin-film solar cell can be cost-effective because of minimal material usage, flexibility, and potential high efficiency. The traditional thin-film solar techno

Get Started

Thin-Film Solar Panels: An In-Depth Guide

Mar 12, 2022 · The idea for thin-film solar panels came from Prof. Karl Böer in 1970, who recognized the potential of coupling thin-film photovoltaic cells with

Get Started

Global and China Photovoltaic Glass

May 21, 2019 · Many a foreign player like AGC has withdrawn from the market, and only a few such as Saint-Gobain still have some small kilns producing PV glass. Chinese PV glass

Get Started

Photovoltaic Glass Waste Recycling in the Development of Glass

Abstract Because of the increasing demand for photovoltaic energy and the generation of end-of-life photovoltaic waste forecast, the feasibility to produce glass substrates for photovoltaic

Get Started

What is thin-film PV? | PVthin

A thin-film solar cell is a solar cell that is made by depositing one or more ultra-thin layers (much thinner than a human hair), or thin-film of photovoltaic

Get Started

6 FAQs about [20 000 pieces of thin-film photovoltaic glass]

What are the new thin film PV technologies?

Emerging next generation thin film technologies With intense R&D efforts in materials science, several new thin-film PV technologies have emerged that have high potential, including perovksite solar cells, Copper zinc tin sulfide (Cu 2 ZnSnS 4, CZTS) solar cells, and quantum dot (QD) solar cells.

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

What are thin film solar cells?

Thin film solar cells are favorable because of their minimum material usage and rising efficiencies. The three major thin film solar cell technologies include amorphous silicon (α-Si), copper indium gallium selenide (CIGS), and cadmium telluride (CdTe).

Are thin film solar panels reliable?

The reliability of thin film is questionable in comparison with the emergence and production of competitive and low-cost crystalline silicon solar panels.

Are CIGS and CdTe the future of thin film solar cells?

CIGS and CdTe hold the greatest promise for the future of thin film. Longevity, reliability, consumer confidence and greater investments must be established before thin film solar cells are explored on building integrated photovoltaic systems. 1. Introduction

What are the different types of Photovoltaic Glass?

These three products have entirely different characteristics and functions, leading to significant differences in their added value. Currently, the most widely used photovoltaic glass is high-transparency glass, known as low-iron glass or extra-clear glass. Iron in ordinary glass, excluding heat-absorbing glass, is considered an impurity.

Related Articles

-

Crystalline silicon and thin-film architectural photovoltaic glass

Crystalline silicon and thin-film architectural photovoltaic glass

-

Togo s photovoltaic glass manufacturers for export

Togo s photovoltaic glass manufacturers for export

-

Glass thickness of double-glass photovoltaic modules

Glass thickness of double-glass photovoltaic modules

-

Photovoltaic glass has color difference

Photovoltaic glass has color difference

-

Photovoltaic powered glass

Photovoltaic powered glass

-

Tajikistan double glass photovoltaic curtain wall price

Tajikistan double glass photovoltaic curtain wall price

-

The role of glass in photovoltaic modules

The role of glass in photovoltaic modules

-

Ethiopia glass photovoltaic sun room

Ethiopia glass photovoltaic sun room

-

Photovoltaic glass reflection loss

Photovoltaic glass reflection loss

-

Differences between cadmium telluride glass and traditional photovoltaic panels

Differences between cadmium telluride glass and traditional photovoltaic panels

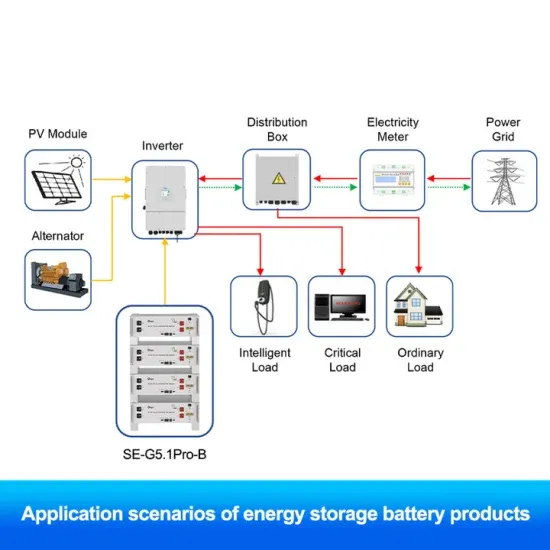

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.