Double Glass Solar Panel Thickness Guide: Find

Mar 5, 2025 · Compare double glass solar panel thickness configurations for international projects. Includes custom small-format options under 200W for

Get Started

Protecting solar panels from hail—the thicker

Sep 12, 2023 · The increasing frequency and severity of hailstorms puts solar panels at risk of damage. Researchers in India and Hong Kong explored the

Get Started

Thinner, Taller Solar Modules Prone To

Dec 13, 2024 · Most solar PV modules in power plants now use two pieces of glass. Based on a brief comparison of glass thickness, the report found:

Get Started

A Rational Strength Prediction Approach to the Design of Double-Glass

Jun 18, 2014 · A rational and systematic approach to estimate the load resistance and strength of various double-glass photovoltaic modules is demonstrated. The approach consists of three

Get Started

Glass-Glass PV Modules

4 days ago · The weight of glass-glass modules are still an issue, with current designs using 2 mm thick glass on each side for framed modules, the weight

Get Started

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · By choosing heat strengthened glass panels on both sides, we have been able to use a thickness of 2.5mm and to demonstrate an excellent module resistance to all standard

Get Started

7 Advantages of Bifacial Glass-Backsheet

Aug 23, 2023 · Bifacial solar PV modules, commonly known as Bifacial solar panels, generate power from both the front and rear, or backside, of the

Get Started

Presentation

Jun 1, 2023 · Currently, glass-glass modules (~15.2 kg/m2) are about 35-40% heavier per unit area than glass-backsheet modules (~11.3 kg/m2)* Almaden advertises 2mm double glass

Get Started

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the glass used on solar photovoltaic modules, which has the important value of protecting cells and transmitting

Get Started

untitled []

Nov 28, 2019 · A glass-glass-module based on thin toughened glass on the front and back of a solar photovoltaic module can have a dramatic impact on its environmental capabilities.

Get Started

Technical properties of Onyx Solar Photovoltaic

3 days ago · The multifunctional properties of photovoltaic glass surpass those of conventional glass. Onyx Solar photovoltaic glass can be customized to

Get Started

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some

Get Started

Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Get Started

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · ECONOMICS Bifacial G2G technology is a turning point in photovoltaic (PV) system technology. It replaces costly single-axis and double-axis mechanical tracking systems with

Get Started

What is the solar panel thickness in 2020?

Oct 24, 2020 · From this picture, we know that A solar PV module consists of solar cells, glass, EVA, backsheet, and frame. Among these components, the

Get Started

Ultra-thin Rolled Photovoltaic Glass – New Way

Jun 16, 2024 · The thickness of rolled photovoltaic glass has gradually transitioned from 3.2 mm and 2.5 mm to 2.0 mm and below. Especially in

Get Started

Top 5: Factors Responsible for Glass Breakage in

Mar 13, 2025 · Glass breakage is a growing concern for the solar power plant operators. With the trend towards double glass sided modules as seen in

Get Started

(PDF) The Performance of Double Glass

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance

Get Started

Thickness of double-sided glass of photovoltaic panels

, when the interlayer shear modulus G c -> 0, the effective thickness of the double-glass photovoltaic module is h w e = (h 1 3 + h 2 3) 1 / 3, which is consistent with the effective

Get Started

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · For instance, the transition from 3.2mm to 2.8mm for single-glass modules and 2mm for double-glass modules, and even to 1.6mm,

Get Started

What is the thickness of the double glass of photovoltaic

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the

Get Started

Hail-prone areas may require solar modules with

Aug 9, 2023 · The group compared three PV modules with different thicknesses to their front glass – 2.8 mm, 3.2 mm, and 4 mm – under various hail sizes,

Get Started

Photovoltaic double-glass panel glass thickness

The thickness of PV glass plays a crucial role in its structural integrity and performance: Range: Common thicknesses range from 3.2mm to 6mmfor individual glass panes. Configurations:

Get Started

Photovoltaic double-glass panel glass thickness

Photovoltaic double-glass thicknes panel glass What is the thickness of PV glass? icknesses range from 3.2mm to 6mmfor individual glass panes. Configurations: Total thickness varies

Get Started

Double the strengths, double the benefits

Feb 21, 2025 · In the ever-evolving world of photovoltaic technology, double glass solar modules are emerging as a game-changer. By encapsulating solar cells

Get Started

INSTRUCTIONS FOR PREPARATION OF PAPERS

3 days ago · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

Get Started

Double glass solar module | Maysun Solar

Why Choose Double Glass Solar Modules? Glass-glass solar modules (bifacial modules) increase energy production by approximately 2% to 5% compared to

Get Started

New tests needed to explain high breakage rates

Feb 24, 2025 · A high breakage rate in thin PV module glass is a vulnerability that is not yet widely understood due to inadequate testing regimes.

Get Started

Building-integrated photovoltaic applied Bi-facial photovoltaic module

Jun 1, 2024 · The criteria for minimizing the glass thickness in commercial glass-to-glass photovoltaic modules for a lightweight design are derived from the experimental results and

Get Started

Glass/Glass Photovoltaic Module Reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

Get Started

Double the strengths, double the benefits

Feb 21, 2025 · At IBC SOLAR, we use 2,0 mm x 2,0 mm glass layers, whereas some other market offerings use thinner 1,6 mm x 1,6 mm layers. This ensures

Get Started

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

Get Started

Lamination process and encapsulation materials for

May 21, 2024 · Lamination process and encapsulation materials for glass–glass PV module design Gianluca Cattaneo1, Antonin Faes1, Heng-Yu Li1,2, Federico Galliano1,2, Maria

Get Started

Thermal and electrical performance analysis of monofacial double-glass

Nov 1, 2023 · The monofacial double-glass photovoltaic modules are still seriously affected by the temperature effect. The coatings with spectral regulation characteristics are expected to

Get Started

6 FAQs about [Glass thickness of double-glass photovoltaic modules]

What is the thickness of a glass module?

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

What is double glass photovoltaic module?

Preface To further extend the s rvice life of photovoltaic modules, double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

How much does a glass module weigh?

The weight of glass-glass modules are still an issue, with current designs using 2 mm thick glass on each side for framed modules, the weight is about 22 kg, while 2.5 mm on each side will increase the module’s weight to 23 kg. Compared to traditional glass-foil modules, which are about 18 kg, this is a 20% increase in weight.

What is the thickness of a dualsun module?

Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below. In both configurations, the photovoltaic cells are laminated between the front and rear sides of the module using an encapsulation material.

Why is white double glass PV module more powerful than transparent?

Due to the high reflectance of white EVA, the power of white double glass module is higher than that of transparent double glass module by 2-4%. Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun.

Related Articles

-

What is the double-glass glass of photovoltaic modules

What is the double-glass glass of photovoltaic modules

-

Photovoltaic panel glass thickness

Photovoltaic panel glass thickness

-

Glass surface of photovoltaic modules

Glass surface of photovoltaic modules

-

Botswana double glass photovoltaic modules

Botswana double glass photovoltaic modules

-

Which one should I choose for single-glass or double-glass photovoltaic modules

Which one should I choose for single-glass or double-glass photovoltaic modules

-

Which company has the best double-glass photovoltaic modules in Lyon France

Which company has the best double-glass photovoltaic modules in Lyon France

-

Creepage distance of photovoltaic double-glass modules

Creepage distance of photovoltaic double-glass modules

-

Double-glass photovoltaic modules for export

Double-glass photovoltaic modules for export

-

Glass sun room roof for photovoltaic

Glass sun room roof for photovoltaic

-

Crystalline silicon and thin-film architectural photovoltaic glass

Crystalline silicon and thin-film architectural photovoltaic glass

Commercial & Industrial Solar Storage Market Growth

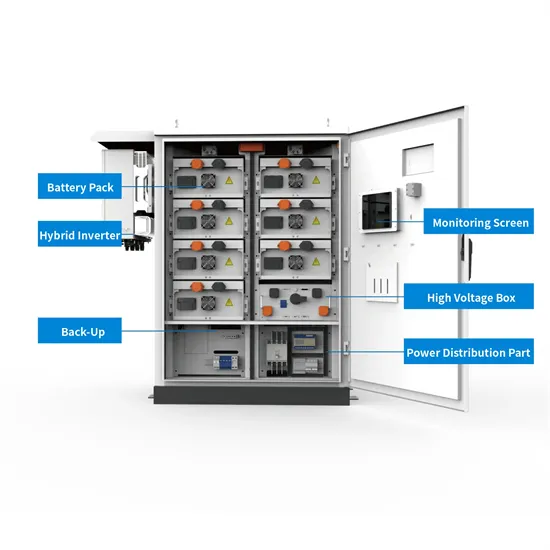

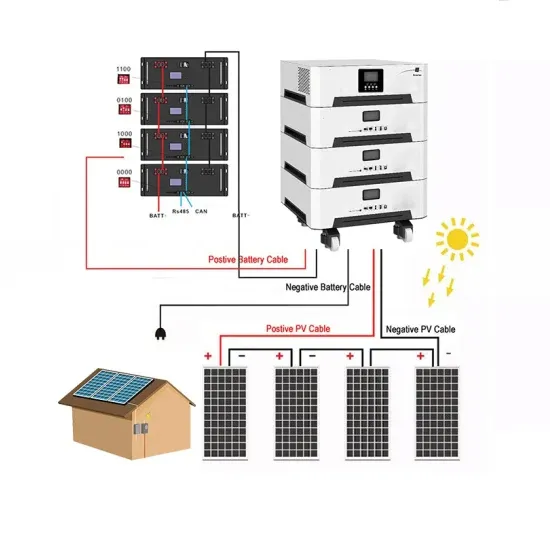

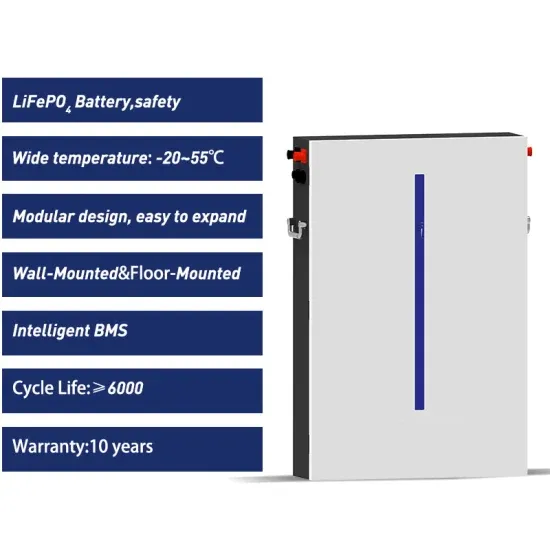

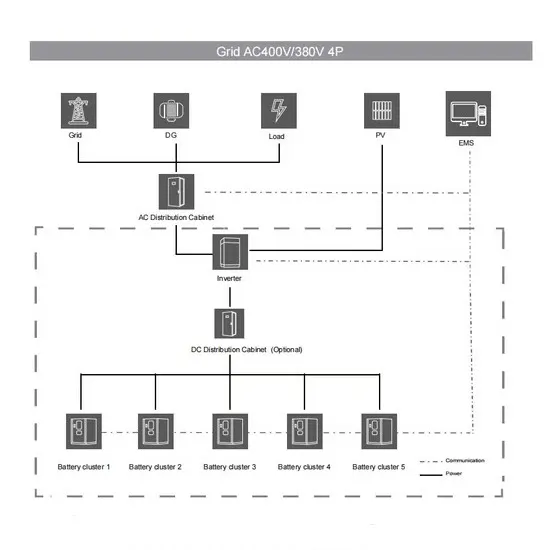

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.