Effects of PV Module Soiling on Glass Surface Resistance

Dec 3, 2015 · It is anticipated that some soil types deposited on module glass will cause decreased surface resistance, leading to extension of the potential of a grounded module

Get Started

Effects of PV Module Soiling on Glass Surface Resistance

Nov 4, 2015 · Effects of PV Module Soiling on Glass Surface Resistance and Potential-Induced Degradation Peter Hacke,1 Patrick Burton,2 Alex Hendrickson, 2Sergiu Spataru,3 Stephen

Get Started

Effects of Glass Texturing Structure on the Module

– that these textured surfaces increase the amount of scattered light and reduce reflectance on the glass surface. In addition, the optical transmittance of the textured glass was markedly

Get Started

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · The most important determinant is the crystalline silicon technology in photovoltaic modules, followed by the protection of photovoltaic glass in photovoltaic modules. Photovoltaic

Get Started

Characterisation of soiling on glass surfaces and their impact

Jan 1, 2024 · Photovoltaic (PV) module soiling, i.e., the accumulation of soil deposits on the surface of a PV module, directly affects the amount of solar energy received by the PV cells in

Get Started

Enhanced thermal performance of photovoltaic panels based on glass

Nov 1, 2021 · In this work, we explore the modification of the external surface of the protective glass that is employed as front cover in the photovoltaic modules to obtain the optimum

Get Started

Anti-soiling coatings for solar cell cover glass: Climate and surface

Oct 1, 2018 · One of these factors is the soiling effect caused by dust accumulation on module surface that reduces the transparency of the PV cover glass over time and consequently

Get Started

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · The choice of glass in a PV module has become a key consideration in efforts to improve durability in the face of extreme weather

Get Started

Fundamentals of soiling processes on photovoltaic modules

Dec 1, 2018 · Furthermore, once dew is present on the PV module surface, the water can interact with dust particles and the glass surface until it evaporates completely during the day when the

Get Started

Investigation of combustion hazards of glass photovoltaic

May 15, 2025 · The glass panel of the photovoltaic module features a white glass cover on its front surface, while its rear side is covered with a white photovoltaic backsheet film, as

Get Started

Glass-Glass PV Modules

4 days ago · Glass-Glass module designs are an old technology that utilises a glass layer on the back of modules in place of traditional polymer backsheets.

Get Started

Glass/Glass Photovoltaic Module Reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

Get Started

Front glass crack inspection of thin-film solar photovoltaic modules

May 15, 2024 · Ensuring the structural integrity of solar photovoltaic modules is crucial to maintain power production efficiency and fulfill the anticipated product

Get Started

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency. Advances in glass compositions,

Get Started

Physical Properties of Glass and the Requirements for

Feb 16, 2011 · Weathering of float glass can be categorized into two stages: "Stage I": Ion-exchange (leaching) of mobile alkali and alkaline-earth cations with H+/H3O+, formation of

Get Started

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Demand for solar photovoltaic glass has surged with the growing interest in green energy. This article explores ultra-thin, surface-coated, and

Get Started

Laser-induced texturing: A sustainable approach to self

Feb 1, 2025 · As per detailed thorough research we did not find any review article related to laser texturing for self-cleaning of solar glass. Sefcondly, the found literature remains limited for the

Get Started

Multifunctional coatings for solar module glass

Apr 22, 2024 · Abstract Currently, single-layer antireflection coated (SLARC) solar glass has a dominant market share of 95% compared to glass with other

Get Started

A review of self-cleaning coatings for solar photovoltaic

Jul 27, 2023 · TiO 2 is widely used to prepare super-hydrophilic coatings on glass covers of photovoltaic panels due to its good photocatalytic activity. CVD-based surface treatment is

Get Started

Improvement Options for PV Modules by Glass Structuring

Sep 20, 2023 · ABSTRACT: The structuring of glass surfaces offers a wide area of application for photovoltaics: Increasing the energy yield and decreasing glare are achievable and become

Get Started

Durable and multifunctional coating design with

Dec 1, 2024 · The goal of this study is to develop a durable and multifunctional coating with superhydrophobicity, high light transmittance and strong infrared radiation, which is applied to

Get Started

Designs for photovoltaic glass surface texturing

Dec 27, 2024 · Planar glass cover creates optical reflection loss and glare, which is harmful to energy efficiency and effective operation of PV modules,

Get Started

An overall introduction to photovoltaic glass –

Jan 24, 2024 · Photovoltaic glass refers to the encapsulating glass used in solar photovoltaic modules, it is generally used on the upper surface of photovoltaic

Get Started

Determination of the effects of temperature changes on solar glass

Jan 1, 2020 · Solar glass is one of the most important components of PV modules and it protects solar cells from harsh environmental conditions. Considering that th

Get Started

The performance and durability of Anti-reflection coatings

Sep 1, 2023 · PV modules experience reflection losses of ∼4% at the front glass surface. This loss can be mitigated by the use of anti-reflection coatings, which now cover over 90% of

Get Started

Why to choose textured glass for covering on

Nov 24, 2004 · Standard glass and polymer covers on photovoltaic modules can partially reflect the sunlight causing glint and glare. Glint and glare from large

Get Started

The performance and durability of single-layer sol-gel anti

Jan 25, 2019 · A significant source of energy loss in photovoltaic (PV) modules is caused by reflection from the front cover glass surface. Reflection from the cover

Get Started

Thermal and electrical performance analysis of monofacial double-glass

Nov 1, 2023 · The monofacial double-glass photovoltaic modules are still seriously affected by the temperature effect. The coatings with spectral regulation characteristics are expected to

Get Started

6 FAQs about [Glass surface of photovoltaic modules]

What encapsulated glass is used in solar photovoltaic modules?

The encapsulated glass used in solar photovoltaic modules (or custom solar panels), the current mainstream products are low-iron tempered embossed glass, the solar cell module has high requirements for the transmittance of tempered glass, which must be greater than 91.6%, and has a higher reflection for infrared light greater than 1200 nm. rate.

Which materials are used in photovoltaic panels?

The remaining 20 –25% encompassed fiberglass (including reinforcement, insulation, and mineral wool fibers) and specialty glass manufacturing . Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36].

Do PV modules have a reflection loss?

PV modules experience reflection losses of ∼4% at the front glass surface. This loss can be mitigated by the use of anti-reflection coatings, which now cover over 90% of commercial modules.

Why is glass used in PV cells?

Glass mitigates these losses by functioning as a protective layer, optical enhancer, and spectral converter within PV cells. Glass-glass encapsulation, low-iron tempered glass, and anti-reflective coatings improve light management, durability, and efficiency.

Does flat glass improve photovoltaic (PV) panel efficiency?

Flat glass transparency, low-iron glass improves photovoltaic (PV) panel efficiency. This seg- emphasis on energy efficiency and sustainability. Refs. [35, 36]. Based on in-depth analyses of market size, trends, and growth projections. Table 1. Flat glass market. augmented reality and advanced display technologies.

Do PV modules have anti-reflection coatings?

These reflection losses can be addressed by the use of anti-reflection (AR) coatings, and currently around 90% of commercial PV modules are supplied with an AR coating applied to the cover glass , . The widespread use of AR coatings is a relatively recent development.

Related Articles

-

The role of glass in photovoltaic modules

The role of glass in photovoltaic modules

-

Huawei polycrystalline silicon double glass photovoltaic modules

Huawei polycrystalline silicon double glass photovoltaic modules

-

What is the double-glass glass of photovoltaic modules

What is the double-glass glass of photovoltaic modules

-

Photovoltaic glass surface

Photovoltaic glass surface

-

Photovoltaic installation in glass house

Photovoltaic installation in glass house

-

Photovoltaic glass curtain wall specifications and standards

Photovoltaic glass curtain wall specifications and standards

-

Photovoltaic glass stripes are large

Photovoltaic glass stripes are large

-

Photovoltaic glass pressing processing

Photovoltaic glass pressing processing

-

Does the photovoltaic integrated module have double glass

Does the photovoltaic integrated module have double glass

-

Photovoltaic module rear glass size

Photovoltaic module rear glass size

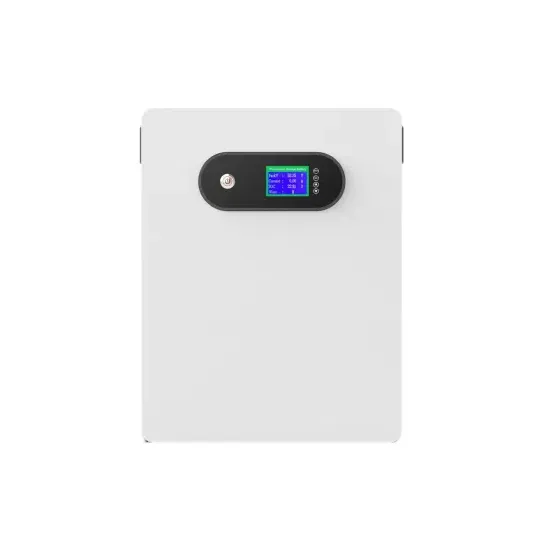

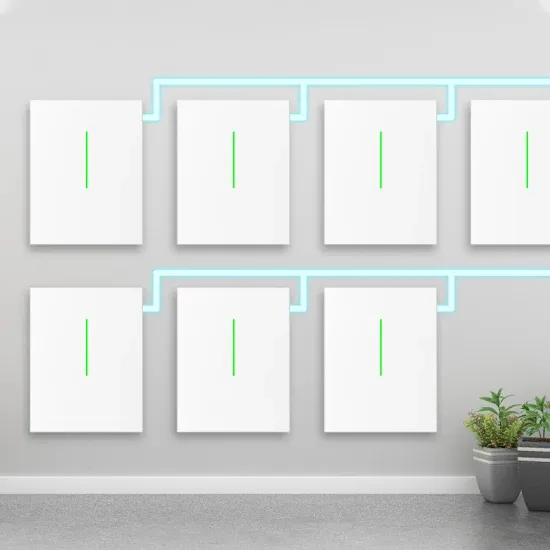

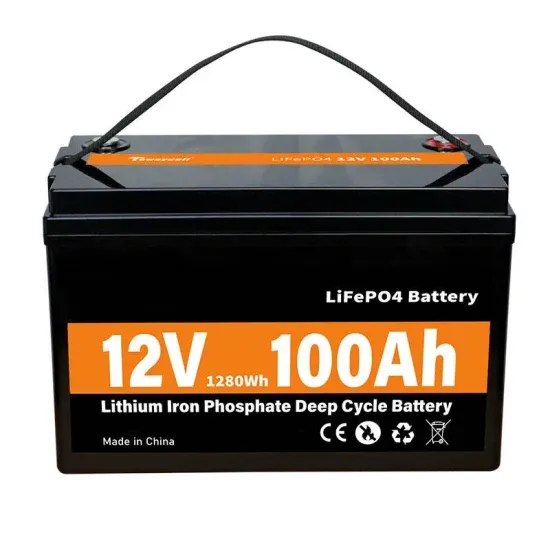

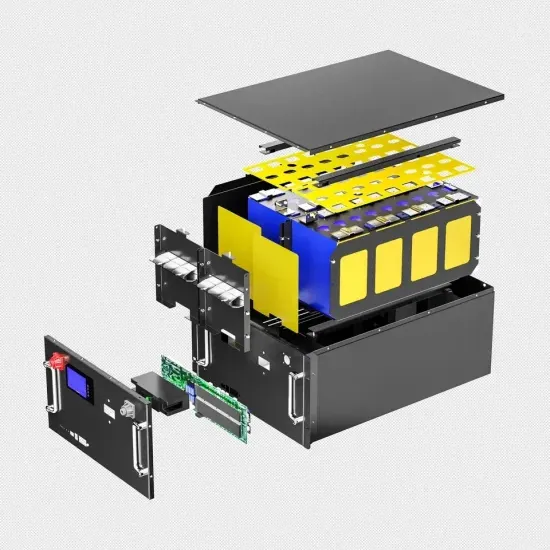

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.