Microsoft Word

Aug 18, 2021 · By assuming that these cycles were repeated daily, the batteries'' lifetime could be predicted using the formula of the remaining capacity of the proposed models, as shown in Eq.

Get Started

Experimental Study of Battery Parameters and Their

Jan 29, 2024 · In this paper, we present battery parameters measured during cycle aging of a 12V, 200Ah sealed lead acid battery over 70 and 180 cycles and the corresponding assessed

Get Started

Lead-Acid Battery Lifetime Estimation using Limited

Oct 23, 2024 · Abstract—Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as well as to optimize

Get Started

Connecting batteries in parallel – BatteryGuy Knowledge Base

May 3, 2024 · There are two ways to wire batteries together, parallel and series. The illustration below show how these wiring variations can produce different voltage and amp hour outputs.

Get Started

LEAD ACID BATTERIES

Aug 2, 2021 · 1. Introduction Lead acid batteries are the most common large-capacity rechargeable batteries. They are very popular because they are dependable and inexpensive

Get Started

Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

Get Started

A comparison of lead-acid and lithium-based battery

Oct 1, 2013 · All of the lithium-based battery chemistries show less capacity fade and better performance in accelerated wind-charged conditions than lead-acid batteries, but the long

Get Started

Aging mechanisms and service life of lead–acid batteries

Mar 10, 2004 · In lead–acid batteries, major aging processes, leading to gradual loss of performance, and eventually to the end of service life, are: • Anodic corrosion (of grids, plate

Get Started

Choosing the Right Battery for Base Stations: LiFePO4 vs. Lead-Acid

LiFePO4batteries and lead-acid batteries are used in base stations, mainly consideringthat different discharge rates have less influence on the discharge capacity ofsuch batteries, and

Get Started

5G base station application of lithium iron phosphate battery

Jan 19, 2021 5G base station application of lithium iron phosphate battery advantages rolling lead-acid batteries With the pilot and commercial use of 5G systems, the large power consumption

Get Started

Battery Sizing Considerations IEEE 2020

Mar 11, 2020 · Spring motor rewind/charge Usually sequential, but can be simultaneous 6s (Ni-Cd) and 1min (Pb-acid)* minimum Continuous loads 20mins to 24hrs (8hr most common)

Get Started

A Guide To Lead-Acid Batteries

Dec 5, 2020 · Structure and Operation Most lead-acid batteries are constructed with the positive electrode (the anode) made from a lead-antimony alloy with lead (IV) oxide pressed into it,

Get Started

Lead-Acid Battery Lifetime Estimation using

Mar 10, 2022 · Abstract Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as

Get Started

The Road to Silicon Batteries: From Lead-Acid to Nickel

Mar 17, 2025 · Explore the evolution of rechargeable batteries, from lead-acid to silicon, and how each innovation transformed energy storage for EVs, electronics, and beyond.

Get Started

The Characteristics and Performance Parameters

Oct 16, 2023 · The Bottom Line Lead-acid batteries remain relevant due to their distinctive characteristics and performance parameters. From the nominal

Get Started

How Does Discharge Rate Affect Battery Capacity

Aug 6, 2025 · Discharge rate significantly affects battery capacity. The faster you drain a battery, the less total energy it delivers. This phenomenon, called the rate-capacity effect, impacts

Get Started

Aging mechanisms and service life of lead–acid batteries

Mar 10, 2004 · In lead–acid batteries, major aging processes, leading to gradual loss of performance, and eventually to the end of service life, are:•Anodic corrosio

Get Started

How Lead-Acid Batteries Age and Fail

Jan 9, 2025 · The three main ways how lead-acid batteries age include positive grid corrosion, sulfation, and internal short circuits. We unpack these here.

Get Started

What Is Battery Capacity a Measure Of

Aug 15, 2025 · Charge/Discharge Rate Considerations The Peukert Effect explains how capacity diminishes at higher discharge rates: Lead-acid batteries: A 100Ah battery at 20A discharge

Get Started

A practical understanding of lead acid batteries

Aug 29, 2021 · Lead acid batteries hate being deep discharged The common rule of thumb is that a lead acid battery should not be discharged below 50% of

Get Started

(PDF) LEAD-ACİD BATTERY

Jan 18, 2022 · The lead-acid battery is the oldest and most widely used rechargeable electrochemical device in automobile, uninterrupted power

Get Started

Lead-Acid Battery Lifetime Estimation using Limited

Jan 21, 2024 · For cellular bases stations where lead acid batteries can cycle with various rates and operate under different conditions, battery lifetime varies between 2 to 5 years. A battery

Get Started

On Backup Battery Data in Base Stations of Mobile

Jan 17, 2022 · On the other hand, Lead-acid batteries in Fig. 1(a) have large capacities and thus have been widely used for storage in backup power supplies in base stations. The aging

Get Started

Life cycle assessment of electric vehicles'' lithium-ion batteries

Nov 1, 2023 · A comparative analysis model of lead-acid batteries and reused lithium-ion batteries in energy storage systems was created.

Get Started

Lithium Iron Batteries for Telecommunications Base Stations

REVOV''s lithium iron phosphate (LiFePO4) batteries are ideal telecom base station batteries. These batteries offer reliable, cost-effective backup power for communication networks. They

Get Started

Lead-Acid Battery Lifetime Estimation using Limited Labeled

Apr 8, 2022 · To extend the number of labels, we propose an active semi-supervised SVM method with minimum human efforts. Finally, the obtained labeled dataset is fed into random

Get Started

Industrial Battery Capacity Variation During Life

Initial capacity upon delivery typically ranges between 90-100%, with some batteries requiring several charge-discharge cycles or years of float operation to reach full rated capacity. IEEE

Get Started

-

Jan 10, 2023 · o The IEEE publishes two recommended practices for battery sizing - IEEE 4851 for lead-acid, and IEEE 11152 for nickel-cadmi. m. In both documents, the recommendation is

Get Started

6 FAQs about [Capacity and age of lead-acid batteries in base stations]

What is the end of life of a lead-acid battery?

r. Thus, IEEE and other documents define the end of life of a lead-acid battery as the point at which the available capacity has fallen to 80% of rated capaci y.Figure 1 also shows the aging characteristics of nickel-cadmium batteri

Why does a lead-acid battery have a low service life?

On the other hand, at very high acid concentrations, service life also decreases, in particular due to higher rates of self-discharge, due to gas evolution, and increased danger of sulfation of the active material. 1. Introduction The lead–acid battery is an old system, and its aging processes have been thoroughly investigated.

What is a lead-acid battery?

The lead-acid (PbA) battery was invented by Gaston Planté more than 160 years ago and it was the first ever rechargeable battery. In the charged state, the positive electrode is lead dioxide (PbO2) and the negative electrode is metallic lead (Pb); upon discharge in the sulfuric acid electrolyte, both electrodes convert to lead sulfate (PbSO4).

What are the major aging processes in lead-acid batteries?

The major aging processes in lead–acid batteries are: Anodic corrosion (of grids, plate-lugs, straps, posts). Positive active mass degradation (shedding, sludging) and loss of adherence to the grid. Irreversible formation of lead sulfate in the active mass (crystallization, sulfation). Short-circuits. Loss of water.

What is the aging margin for lead-acid battery sizing?

Upload your project docs. # Lead-Acid Battery Capacity Variation Throughout Service Life ## IEEE-485-2010 Standard: Aging Margin Justification The IEEE-485-2010 standard recommends including a 1.25 aging margin in lead-acid battery sizing calculations due to predictable capacity degradation patterns.

Do lead-acid batteries have a limited capacity?

y. This is particularly the case in telecom systems where battery space is limit d.Lead-acid batteries exhibit a characteristic pattern of capacity availability through life, as illustrated in Figure 1. These batteries actually spend half their lives or more above 100% of their rated capaci

Related Articles

-

Connection between lead-acid batteries in communication base stations

Connection between lead-acid batteries in communication base stations

-

Where to move the lead-acid batteries for Portugal s communication base stations

Where to move the lead-acid batteries for Portugal s communication base stations

-

Maintenance plan for lead-acid batteries in communication base stations

Maintenance plan for lead-acid batteries in communication base stations

-

Tender for lead-acid batteries for communication base stations in Senegal

Tender for lead-acid batteries for communication base stations in Senegal

-

Tender for lead-acid batteries for Maputo communication base stations

Tender for lead-acid batteries for Maputo communication base stations

-

Distribution of lead-acid batteries for communication base stations in the Solomon Islands

Distribution of lead-acid batteries for communication base stations in the Solomon Islands

-

Comparison of hybrid power sources of lead-acid batteries for communication base stations in various industries

Comparison of hybrid power sources of lead-acid batteries for communication base stations in various industries

-

Technical Specifications for Photovoltaic Power Generation with Lead-acid Batteries for Communication Base Stations

Technical Specifications for Photovoltaic Power Generation with Lead-acid Batteries for Communication Base Stations

-

Can vanadium batteries be used in communication base stations

Can vanadium batteries be used in communication base stations

-

Are lithium batteries used a lot in telecom base stations

Are lithium batteries used a lot in telecom base stations

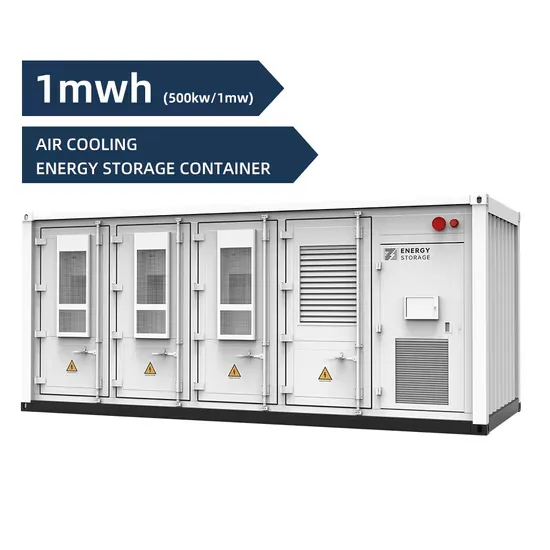

Commercial & Industrial Solar Storage Market Growth

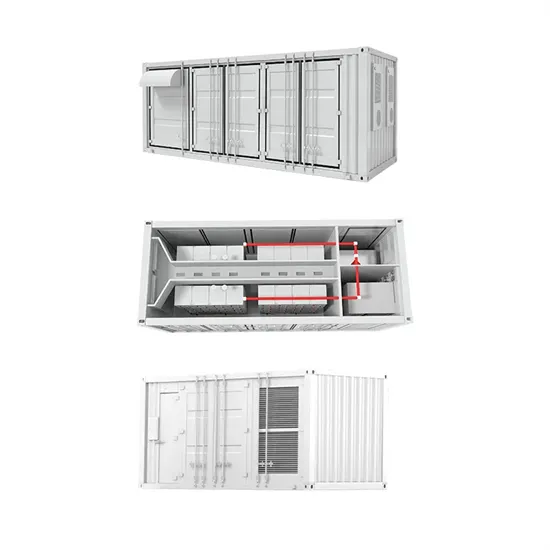

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.