Photovoltaic solar energy: generating electricity

Dec 18, 2009 · Photovoltaic energy is a form of renewable energy obtained from solar radiation and converted into electricity through the use of photovoltaic

Get Started

Photovoltaic Glass

Dec 17, 2020 · The production process of photovoltaic glass is mainly divided into two major links: original sheet production and deep processing. The original sheet production is the untreated

Get Started

Standard and production of photovoltaic glass

Photovoltaic glass silica sand is an important raw material for photovoltaic glass production. The raw materials of photovoltaic glass silica sand include natural

Get Started

CHARACTERISTICS OF PHOTOVOLTAIC GLASS FOR PHOTOVOLTAIC

The photovoltaic industry chain can be divided into five links: silicon material, silicon wafer, photovoltaic cell, photovoltaic module, and photovoltaic system. Upstream includes the

Get Started

Crystalline Silicon Solar Cell

These types of solar cells are further divided into two categories: (1) polycrystalline solar cells and (2) single crystal solar cells. The performance and efficiency of both these solar cells is almost

Get Started

What is photovoltaic glass

Dec 9, 2021 · What is photovoltaic glass? Photovoltaic (PV) glass is a glass that utilizes solar cells to convert solar energy into electricity. It is installed within

Get Started

Solar Photovoltaic Glass: Classification and

Jun 26, 2024 · Depending on their properties and manufacturing methods, photovoltaic glass can be categorized into three main types: cover plates for

Get Started

Sustainable Management of Photovoltaic Waste

Jan 10, 2025 · The rapid expansion of photovoltaic (PV) technology as a source of renewable energy has resulted in a significant increase in PV panel waste,

Get Started

Solar Photovoltaic Glass Market Size, Share

Oct 26, 2023 · Solar photovoltaic glass market to reach USD 243.7 billion by 2033, growing at a CAGR of 30.5% due to rising demand for renewable

Get Started

The main components of photovoltaic glass

Dec 31, 2024 · The preparation process of photovoltaic glass generally uses the rolling method, and the production process is divided into two stages: raw

Get Started

What is the difference between solar thermal

Aug 8, 2023 · What is the difference between a solar PV (photovoltaic) and a solar thermal system? The core difference is how they work. First,

Get Started

Comprehensive review of environmental factors influencing

Jun 1, 2023 · On the basis of an in-depth analysis of the relevant published literature, the various mitigation techniques have been divided into two primary categories: (i) circuit-based

Get Started

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · What are the classifications of photovoltaic glass? The classification of photovoltaic glass mainly includes ultra white photovoltaic

Get Started

Photovoltaic vs Solar Panels: Understanding the

Solar panels can be divided into two main categories: photovoltaic (PV) panels and solar thermal panels. Photovoltaic Panels: Converting Sunlight into

Get Started

Photovoltaic System

Then, the individual PV cells are assembled into framed PV panels, and finally the PV system is completed by the addition of the BOS. There are more steps to arrive at the final stage in c-Si

Get Started

Solar Photovoltaic Glass Market | Trends & Forecast 2025

Explore the global Solar Photovoltaic Glass Market size, growth trends, key players, and future outlook through 2025 in this comprehensive industry analysis.

Get Started

Life Cycle-Based Carbon Emission Reduction

Nov 27, 2023 · Based on such method and concepts, the operations of the centralized PV power plants have been divided into certain categories, as

Get Started

Production of Porous Glass-Foam Materials from Photovoltaic

Jul 3, 2023 · The solar energy production is growing quickly for the global demand of renewable one, decrease the dependence on fossil fuels. However, disposing of used photovoltaic (PV)

Get Started

Solar glass/Photovoltaic glass classification

Aug 27, 2019 · Here we illustrate the classification of the solar glass: Solar glass is divided into two categories, one is ultra-white rolled glass used in crystalline

Get Started

Classification and application of solar photovoltaic glass

Apr 20, 2022 · According to the nature of use and manufacturing method, photovoltaic glass can be divided into three kinds of products, namely the cover plate of flat solar cell, which is

Get Started

Multi-objective evolutionary optimization of photovoltaic glass

Nov 1, 2023 · The potential of fenestration systems is increased by incorporating photovoltaic technology into windows. This recently developed technology enhances

Get Started

An overall introduction to photovoltaic glass –

Jan 24, 2024 · This article will give you a detailed introduction to what photovoltaic glass is, what types there are, the quality requirements of solar

Get Started

PVI19_Front_Cover dd

May 21, 2024 · The requirements for PV module encapsulants in terms of optimizing module efficiency can be divided into five categories: electric yield, electrical safety, reliability, module

Get Started

Production process and classification of

Nov 15, 2021 · At present, there are mainly the following two production processes for photovoltaic glass. (1) The production process of Gridfa glass

Get Started

Environmental analysis and comparison of the conventional

Jul 21, 2024 · There are two major forms of solar energy that are typically utilized: photovoltaic and concentrated applications. The application of fractal glass texture to photovoltaic solar

Get Started

Photovoltaic glass: the perfect fusion between

Aug 18, 2025 · Photovoltaic glass is transparent solar panels designed to replace conventional glass in buildings and structures. These panels are capable of

Get Started

Performances of typical photovoltaic module production

Apr 1, 2024 · Considering the amount of each component of a PV module and the availability of database data, this study considers the production of the following main components:

Get Started

Photovoltaic glass on it? What are its pros and cons?

May 10, 2024 · Its production process is mainly divided into two major links: original film production and deep processing. The production of the original sheet is to obtain the untreated

Get Started

What is Photovoltaic Glass (or solar pv glass)?_

Jul 23, 2025 · However, maintaining and improving the optical properties of photovoltaic glass is much easier and cheaper than developing crystalline silicon with higher conversion rates, so

Get Started

Photovoltaic Cell Generations | Encyclopedia MDPI

Aug 25, 2022 · Polymer/organic photovoltaic cells can also be divided into dye-sensitized organic photovoltaic cells (DSSCs), photoelectrochemical

Get Started

Product | Photovoltaic Glass | JNS TECH

Photovoltaic glass can be divided into two categories: crystalline silicon photovoltaic glass and thin-film photovoltaic glass. Among them, crystalline silicon is commonly used in curtain walls,

Get Started

Glass Application in Solar Energy Technology

Apr 28, 2025 · Flat glass usage is broadly divided into key segments, as outlined in Table 1, including architectural applications (building windows and facades),

Get Started

Photovoltaic Cell Generations and Current

Aug 12, 2022 · The purpose of this paper is to discuss the different generations of photovoltaic cells and current research directions focusing on their

Get Started

Top 10 photovoltaic glass manufacturers in

Aug 20, 2025 · It is usually divided into cover glass for conventional photovoltaic modules, cover and back glass for double glass modules, and TCO glass for

Get Started

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

Get Started

Environmental Impact of PV Power Systems

Aug 2, 2023 · The environmental impacts of solar energy vary widely depending on the technology, which is divided into two basic categories: PV solar power

Get Started

6 FAQs about [The production of photovoltaic glass is divided into two categories]

What is the production process of Photovoltaic Glass?

Production process of photovoltaic glass The deep processing process of photovoltaic glass involves two steps: tempering and coating. The original sheet is ground and then tempered to obtain tempered sheets, or tempered and coated to obtain coated sheets for component packaging.

What is the classification of Photovoltaic Glass?

The classification of photovoltaic glass mainly includes ultra white photovoltaic embossed glass, ultra white processed Float glass, TCO glass and backplane glass. The main characteristics are analyzed as follows: (1) Ultra White Photovoltaic Embossed Glass

What raw materials are used in Photovoltaic Glass production?

The raw materials used in the production of photovoltaic glass raw materials include soda ash, quartz sand, feldspar, dolomite, limestone, mirabilite, etc. Quartz sand and soda ash are not only the main components in material input, but also the two types of raw materials that have a significant impact on material costs.

What is Solar Photovoltaic Glass?

This article explores the classification and applications of solar photovoltaic glass. Photovoltaic glass substrates used in solar cells typically include ultra-thin glass, surface-coated glass, and low-iron (extra-clear) glass.

Which glass is used in photovoltaic power generation?

The glass used in photovoltaic power generation is not ordinary glass, but TCO conductive glass. HHG is a professional glass manufacturer and glass solution provider include range of tempered glass, laminated glass, textured glass and etched glass.

What are solar cells made of?

It is composed of low iron glass, solar cells, film, back glass, and special metal wires. The solar cells are sealed between a low iron glass and a back glass through film, making it the most innovative high-tech glass product for construction. Using low iron glass to cover solar cells can ensure high solar transmittance.

Related Articles

-

Photovoltaic glass production in Birnovo

Photovoltaic glass production in Birnovo

-

Photovoltaic conductive glass production

Photovoltaic conductive glass production

-

Photovoltaic glass production area

Photovoltaic glass production area

-

Kuala Lumpur Photovoltaic Glass Production Plant

Kuala Lumpur Photovoltaic Glass Production Plant

-

Venezuela Future Photovoltaic Glass Production Plant

Venezuela Future Photovoltaic Glass Production Plant

-

Photovoltaic glass for roof

Photovoltaic glass for roof

-

Mozambique photovoltaic glass project construction

Mozambique photovoltaic glass project construction

-

Requirements for glass in photovoltaic products

Requirements for glass in photovoltaic products

-

Solar Photovoltaic Glass Energy Storage System

Solar Photovoltaic Glass Energy Storage System

-

Photovoltaic glass manufacturing ratio

Photovoltaic glass manufacturing ratio

Commercial & Industrial Solar Storage Market Growth

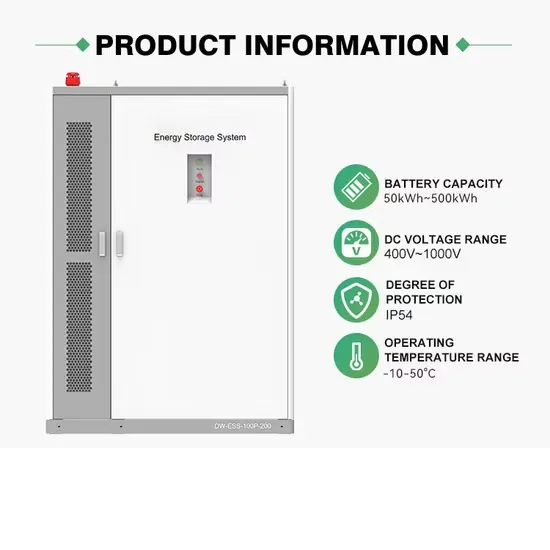

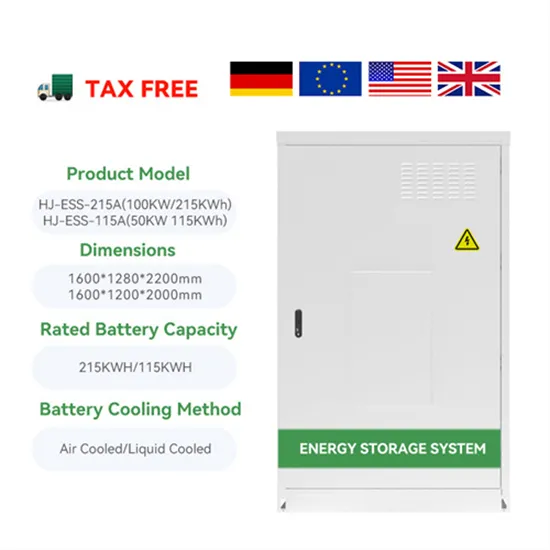

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.