How Are Lithium-Ion Batteries Manufactured

Jun 22, 2025 · Learn how lithium-ion batteries are manufactured step by step, from raw materials to assembly, quality checks, and packaging for safe,

Get Started

The EV Battery Supply Chain Explained

May 5, 2023 · The downstream portion of the EV battery supply chain involves the assembly of battery cells into modules and then packs before placing

Get Started

Lithium‐based batteries, history, current status,

Oct 7, 2023 · The high energy/capacity anodes and cathodes needed for these applications are hindered by challenges like: (1) aging and degradation; (2)

Get Started

(PDF) BATTERY MODULE AND PACK ASSEMBLY

Feb 6, 2019 · Our second brochure on the subject "Assembly process of a battery module and battery pack" deals with both battery module assembly and

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

Lithium battery assembly method and precautions

May 19, 2024 · Lithium battery is a high -energy density battery that is widely used in mobile electronic equipment, electric vehicles and energy storage

Get Started

Battery Balancing: Techniques, Benefits, and How It Works

Learn how battery balancing improves performance, safety, and lifespan. Explore key techniques, benefits, and the science behind balancing battery cells effectively.

Get Started

GLOBAL DEVELOPMENT AND SUSTAINABILITY OF

Jun 30, 2024 · Abstract: The aim of this review was to provide a comprehensive assessment of the global development and sustainability of lithium-ion batteries (LIBs) for electric vehicles.

Get Started

This is why batteries are important for the

Sep 15, 2021 · The main difference is the energy density. You can put more energy into a lithium-Ion battery than lead acid batteries, and they last much

Get Started

Does the World Have Enough Lithium for

Jan 6, 2023 · While the world does have enough lithium to power the electric vehicle revolution, it''s less a question of quantity, and more a question of

Get Started

How Are Lithium Batteries Made? A

Sep 25, 2023 · Introduction With tech zooming ahead, lithium batteries are powering up just about everything. From our phones to our electric rides,

Get Started

How does an EV battery actually work?

Feb 17, 2023 · How does an EV battery actually work? Are lithium batteries sustainable enough to fulfill the dream of the electric-car revolution?

Get Started

General Lithium Ion Battery Safety

Li-ion Battery Safety - Never modify, disassemble, or tamper with the battery. The performance of damaged/modified batteries can be unpredictable and dangerous.

Get Started

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Manufacturing equipment evaluation highlights significant challenges in electrode preparation, cell assembly, and finishing. Using space-saving machinery and cost-effective,

Get Started

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get Started

Lithium-ion batteries

Mar 15, 2016 · This topic is part of our four-part series on batteries. For further reading see how a battery works, types of batteries and batteries of the future.

Get Started

Comprehensive Guide to Battery Assembly

Jun 18, 2024 · Using the right tools and following precise steps is necessary to ensure the battery works properly. This article explores techniques, tools, and

Get Started

Electric vehicle battery production process

6 days ago · Many new and existing application challenges need to be solved in the production process of electric vehicles, batteries, and powertrains. For

Get Started

10 steps in the lithium battery production

5 days ago · 10 steps in lithium battery production for electric cars: from electrode manufacturing to cell assembly and finishing.

Get Started

Ultimate Guide to Equipment for Lithium Battery Assembly

Jan 23, 2025 · Selecting the best equipment for lithium battery assembly involves a step-by-step approach: Assess Your Needs: Determine the scale of production, types of batteries, and

Get Started

Best Practices for Charging, Maintaining, and

Welcome to our comprehensive guide on lithium battery maintenance. Whether you''re a consumer electronics enthusiast, a power tool user, or an electric

Get Started

LITHIUM BATTERIES 101

Apr 28, 2022 · Fact 4: Lead-acid battery life is dramatically affected by constant partial state of charge use Fact 5: Lead-acid batteries have long charge times and low charge efficiencies vs.

Get Started

Battery Plant Design Do''s and Don''ts | ASSEMBLY

Sep 15, 2023 · New battery plants are popping up like wild flowers all over North America, as automakers embark on one of their biggest building sprees ever,

Get Started

Lithium Battery Assembly and Usage Best

Feb 20, 2024 · Correct assembly and use of lithium batteries is the key to ensuring their safety and performance. Let''s learn the assembly methods and

Get Started

Principle of assembling method of lithium

Dec 29, 2020 · To do personal lithium battery assembly, you need to prepare tools and batteries and design and calculate what kind of capacity, voltage,

Get Started

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion batteries use lithium in ionic form instead of in solid metallic form and are usually rechargeable, often without needing to remove the battery from the device. They

Get Started

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · The lithium-ion battery assembly process is a sophisticated, multi-layered operation that relies heavily on precision, quality, and cutting-edge

Get Started

Understanding Global Lithium Battery Standards

Feb 11, 2025 · They have specific standards that ensure the safety of lithium-ion cells in consumer electronics (UL 1642), apply to battery pack durability (UL

Get Started

Understanding EV Battery Warehousing Safety

Oct 17, 2024 · As the electric vehicle (EV) market expands, automotive manufacturers and suppliers face increasingly complex challenges in their

Get Started

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this step-by-step

Get Started

6 FAQs about [Does the assembly of lithium batteries for electric tools need to be balanced ]

What are the safety precautions when using a lithium ion battery?

Do not jumpstart, use other batteries, or use other power sources. Doing so may cause long-term battery damage that can result in burns, fire, or explosion. Li-ion Battery Safety - Never modify, disassemble, or tamper with the battery. The performance of damaged/modified batteries can be unpredictable and dangerous.

What is lithium ion battery assembly?

Lithium-Ion Battery Assembly: Involves stacking layers of anodes, cathodes, and separators. Assembly techniques include winding for cylindrical cells and stacking for prismatic cells. Requires careful handling of liquid electrolytes during assembly. Lithium Polymer Battery Assembly:

What is battery assembly?

Battery assembly is the process of assembling parts to create a functioning battery. This involves combining essential components like cells and connectors. Using the right tools and following precise steps is necessary to ensure the battery works properly.

What tools are used in battery assembly?

Purpose: These tools facilitate safely handling and manipulating battery cells during assembly. Examples: Tweezers, vacuum pens, and cell holders ensure precise positioning and prevent contamination. Importance: Proper handling tools minimize the risk of damage to sensitive battery components and ensure assembly accuracy.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

How do you test a lithium battery pack?

Voltage and Current Testing: Use a multimeter to ensure the pack operates within safe parameters. Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations.

Related Articles

-

Main production areas of lithium batteries for electric tools

Main production areas of lithium batteries for electric tools

-

New uses for lithium batteries in power tools

New uses for lithium batteries in power tools

-

How long does it usually take to charge a lithium battery for electric tools

How long does it usually take to charge a lithium battery for electric tools

-

Do inverter manufacturers need lithium batteries

Do inverter manufacturers need lithium batteries

-

Where to buy lithium batteries for power tools in Pretoria

Where to buy lithium batteries for power tools in Pretoria

-

Comparison of energy storage of various lithium batteries

Comparison of energy storage of various lithium batteries

-

Production of outdoor energy storage lithium batteries

Production of outdoor energy storage lithium batteries

-

Lithium batteries for base stations

Lithium batteries for base stations

-

Does the n-type battery cabinet include lithium batteries

Does the n-type battery cabinet include lithium batteries

-

Companies that sell inverters and lithium batteries

Companies that sell inverters and lithium batteries

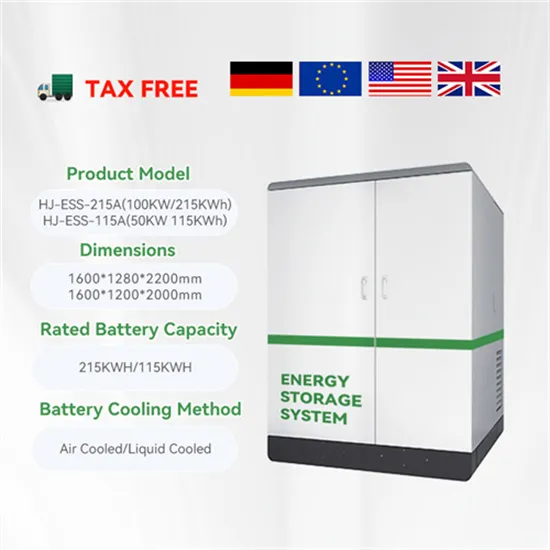

Commercial & Industrial Solar Storage Market Growth

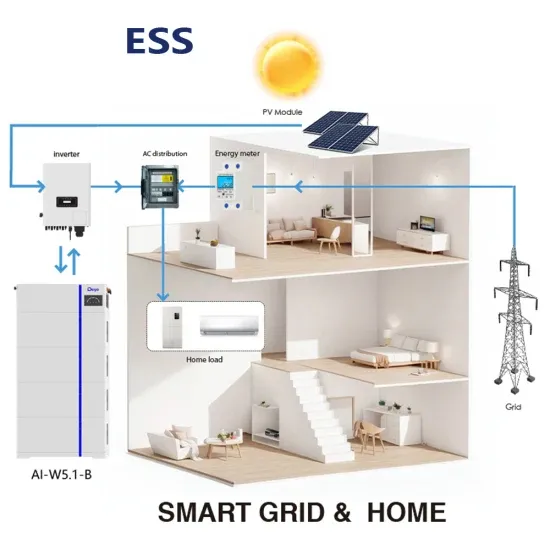

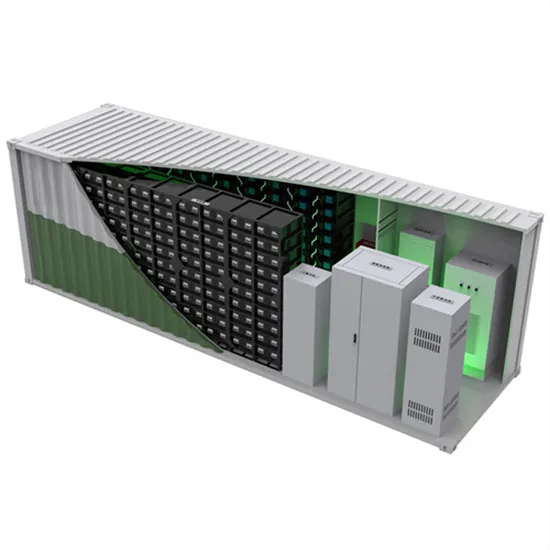

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.