Lithium-Ion Batteries: Types, Safety, Performance

Apr 8, 2025 · What is a Lithium-Ion Battery and How Does it Work? Explore lithium-ion battery types, how they work, cell formats, safety advancements,

Get Started

Bridging the gap between life cycle assessment and lithium

Feb 1, 2025 · An important factor in the success of this transition to electric mobility is the technological development of batteries used as energy carriers in electric vehicles (EVs) [2].

Get Started

In-Depth Analysis of Lithium Battery Manufacturing Processes

Aug 15, 2025 · Material Significance: The essential materials in lithium battery production include lithium, cobalt, and nickel, each contributing unique properties that affect battery performance

Get Started

DRIVING THE FUTURE: PRECISION PRODUCTION OF

DRIVING THE FUTURE: PRECISION PRODUCTION OF LITHIUM-ION BATTERIES FOR ELECTRIC VEHICLES Ten years ago, the market for personal electric vehicles (EVs) was

Get Started

Essential Equipment for Lithium Battery Assembly: Tools,

Apr 24, 2025 · The growing demand for lithium batteries across electric vehicles, consumer electronics, and energy storage systems has made equipment for lithium battery assembly

Get Started

Trends in batteries – Global EV Outlook 2023 –

Aug 19, 2025 · Trends in batteries Battery demand for EVs continues to rise Automotive lithium-ion (Li-ion) battery demand increased by about 65% to 550

Get Started

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion batteries use lithium in ionic form instead of in solid metallic form and are usually rechargeable, often without needing to remove the battery from the device. They

Get Started

How Are Lithium-Ion Batteries Manufactured

Jun 22, 2025 · Learn how lithium-ion batteries are manufactured step by step, from raw materials to assembly, quality checks, and packaging for safe,

Get Started

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Summary Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and

Get Started

A comprehensive review and analysis of technology

Jun 1, 2025 · Thus, we aim at developing comprehensive process overview specifications for state-of-the-art lithium-ion battery cell production by applying a systematic, methodical

Get Started

Top 10 Lithium-Ion Battery Manufacturers In The

Nov 30, 2024 · This article will discuss the top 10 lithium-ion battery manufacturers that play a major role in advancing lithium-ion products; CATL,

Get Started

Full Explanation of Lithium Battery Production

Aug 9, 2024 · What makes lithium-ion batteries so crucial in modern technology? The intricate production process involves more than 50 steps, from electrode

Get Started

Comprehensive Guide to Lithium Production:

Mar 5, 2024 · Lithium-polymer variants provide flexible, lightweight options for modern devices, while lithium iron phosphate batteries are valued for safety

Get Started

Advancing lithium-ion battery manufacturing: novel

Jun 15, 2024 · New production technologies for LIBs have been developed to increase efficiency, reduce costs, and improve performance. These technologies have resulted in significant

Get Started

Lithium is Driving the EV Boom: Demand to

3 days ago · In 2023, vehicles accounted for 80% of lithium-ion battery demand, a figure expected to rise significantly as EV adoption accelerates worldwide.

Get Started

How Lithium Batteries Are Made?The Science

Feb 18, 2025 · Discover how lithium-ion batteries are made, from key materials and production processes to the latest advancements in LFP, NMC, and solid

Get Started

Lithium: Sources, Production, Uses, and Recovery

Jul 11, 2013 · The demand for lithium has increased significantly during the last decade as it has become key for the development of industrial products,

Get Started

Review of Lithium as a Strategic Resource for

Oct 23, 2024 · Abstract and Figures This article presents a comprehensive review of lithium as a strategic resource, specifically in the production of batteries for

Get Started

Lithium: A review of applications, occurrence, exploration,

Sep 1, 2024 · Lithium, and Li-containing compounds and alloys are critical to several key technologies such as lithium-ion batteries which power all our modern electronic gadgets to

Get Started

Top 10 Lithium Battery Manufacturers in China

Jan 26, 2024 · 2025 China top 10 lithium battery manufacturers comparison. Production capacity, UN/IEC certifications, OEM services for EV and energy

Get Started

Advancing energy storage: The future trajectory of lithium-ion battery

Jun 1, 2025 · Lithium-ion batteries have substantially impacted portable electronics, electric vehicles (EVs), and grid-scale storage systems [4]. Their ability to store energy efficiently and

Get Started

Lithium''s Essential Role in EV Battery Chemistry

Nov 19, 2024 · The report says that at present lithium mining is highly concentrated, with over 90% sourced from Australia, Chile, and China. This

Get Started

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share of LIBs h

Get Started

Lithium-ion batteries and the future of sustainable energy: A

The necessity to move away from fossil fuels and diesel-based vehicles to curb their impact on climate change has significantly prompted advancement with electric cars and related battery

Get Started

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The chair "Production Engineering of E-Mobility Components" (PEM) of RWTH Aachen University has been active in the field of lithium-ion battery production technology for

Get Started

Lithium-Ion Battery Manufacturing: Industrial View on

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting with a brief overview of existing

Get Started

Lithium-ion battery demand forecast for 2030

Jan 16, 2023 · The global market for Lithium-ion batteries is expanding rapidly. We take a closer look at new value chain solutions that can help meet the

Get Started

Production of Lithium-Ion Batteries

Apr 24, 2024 · The basic materials for lithium-ion batteries include lithium (as lithium cobalt oxide, lithium iron phosphate, or other compounds), electrode

Get Started

Guide to the Industrialization of Lithium-Ion Batteries in

Sep 23, 2024 · The Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University conducts research in many areas including battery production, electric

Get Started

Review of Lithium as a Strategic Resource for

Oct 23, 2024 · This article presents a comprehensive review of lithium as a strategic resource, specifically in the production of batteries for electric

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · Electrolyte preparation involves: Solvent Selection: Choosing a solvent that ensures good ionic conductivity and stability. Salt Dissolution:

Get Started

Towards the lithium-ion battery production network:

Jul 1, 2022 · The increasing role of electricity as an energy carrier in decarbonising economies is driving a growing demand for electrical energy storage in the form of battery systems. Two

Get Started

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The ''Production Process of a Lithium-Ion Battery Cell'' guide pro-vides a comprehensive overview of the production of different battery cell formats, from electrode

Get Started

The Manufacturing Process of Lithium Batteries Explained

Sep 18, 2024 · Lithium battery manufacturing encompasses a range of processes designed to produce efficient and reliable energy storage solutions. The demand for lithium batteries has

Get Started

Ten major challenges for sustainable lithium-ion batteries

Jun 19, 2024 · Summary Lithium-ion batteries offer a contemporary solution to curb greenhouse gas emissions and combat the climate crisis driven by gasoline usage. Consequently, rigorous

Get Started

Frontiers | Editorial: Lithium-ion batteries:

Dec 13, 2024 · Lithium-ion batteries (LIBs) are critical to energy storage solutions, especially for electric vehicles and renewable energy systems (Choi and

Get Started

6 FAQs about [Main production areas of lithium batteries for electric tools]

What are the production steps in lithium-ion battery cell manufacturing?

Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and cell finishing (formation) based on prismatic cell format. Electrode manufacturing starts with the reception of the materials in a dry room (environment with controlled humidity, temperature, and pressure).

How can a local battery manufacturing system help a battery plant?

Local manufacturers will scale up and cover the entire machinery for a battery plant through collaborations, from producing electrodes to the final cell formation. Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system.

What are the raw materials for battery production?

The raw materials for battery production, including lithium-ion battery manufacturing, are critical for ensuring high-quality output. The foundation of any battery is its raw materials. These materials’ quality and properties significantly impact the final product’s performance and longevity. Typical raw materials include:

How are lithium ion batteries made?

State-of-the-Art Manufacturing Conventional processing of a lithium-ion battery cell consists of three steps: (1) electrode manufacturing, (2) cell assembly, and (3) cell finishing (formation) [8, 10].

How is the quality of the production of a lithium-ion battery cell ensured?

The production parameter settings are adjusted until the specification values are restored. The products produced during this time are sorted according to the severity of the error. In summary, the quality of the production of a lithium-ion battery cell is ensured by monitoring numerous parameters along the process chain.

How battery manufacturing technology is evolving in parallel to market demand?

Hence, battery manufacturing technology is evolving in parallel to the market demand. Contrary to the advances on material selection, battery manufacturing developments are well-established only at the R&D level . There is still a lack of knowledge in which direction the battery manufacturing industry is evolving.

Related Articles

-

Does the assembly of lithium batteries for electric tools need to be balanced

Does the assembly of lithium batteries for electric tools need to be balanced

-

New uses for lithium batteries in power tools

New uses for lithium batteries in power tools

-

How many volts are there in a 21vf lithium battery for electric tools

How many volts are there in a 21vf lithium battery for electric tools

-

Production of outdoor energy storage lithium batteries

Production of outdoor energy storage lithium batteries

-

Lithium battery production using ladder tools

Lithium battery production using ladder tools

-

How long does it usually take to charge a lithium battery for electric tools

How long does it usually take to charge a lithium battery for electric tools

-

Korean electric three-point lithium battery pack

Korean electric three-point lithium battery pack

-

Will lithium batteries be used for energy storage

Will lithium batteries be used for energy storage

-

Burundi energy storage power station bans lithium batteries

Burundi energy storage power station bans lithium batteries

-

Can lithium batteries be connected to photovoltaic panels

Can lithium batteries be connected to photovoltaic panels

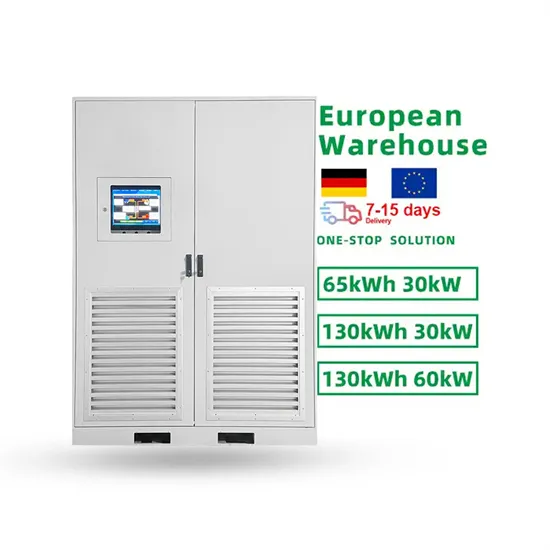

Commercial & Industrial Solar Storage Market Growth

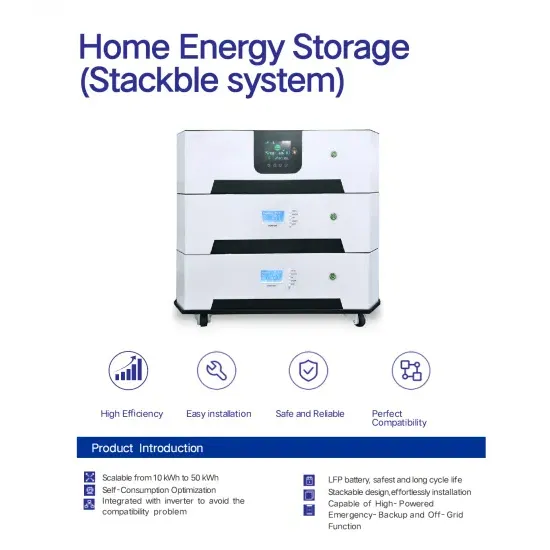

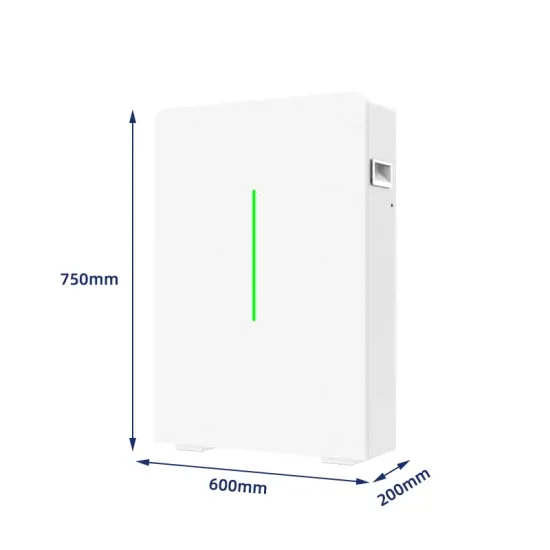

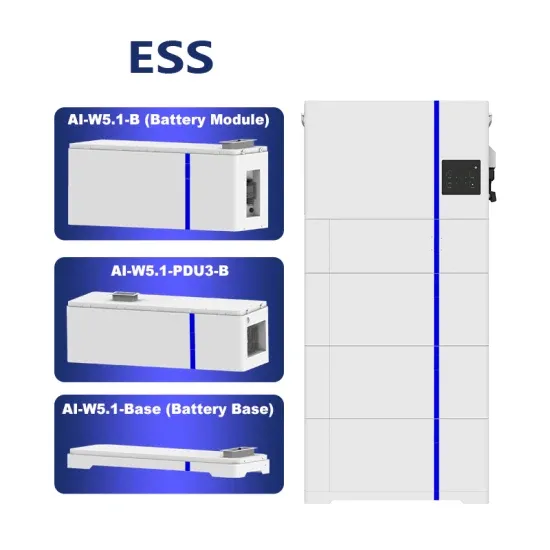

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.