Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Lithium-ion Battery North manufacturing optimizing manufacturing America, battery resource and pathways. cell utilization, faces emerging manufacturRegions global markets,

Get Started

Application Explanation of Ladder Lithium Battery-Corporate

We should guide enterprises in automobile production, battery production and comprehensive utilization to strengthen cooperation, form cross-industry joint communities through various

Get Started

Solutions for Manufacturing and Utilizing Lithium-ion

Apr 10, 2020 · This paper introduces a solution for the production of lithium-ion batteries, for which it is considered to be difficult to provide high-performance specifications in terms of both

Get Started

Essential Equipment for Lithium Battery Assembly: Tools,

Apr 24, 2025 · Lithium battery assembly requires specialized equipment for lithium battery assembly to maintain high precision and efficiency. Key tools include: Automated Assembly

Get Started

How Lithium Batteries Are Made?The Science

Feb 18, 2025 · Discover how lithium-ion batteries are made, from key materials and production processes to the latest advancements in LFP, NMC, and solid

Get Started

Dynamic lithium battery ladder use technology: difficult

Aug 7, 2025 · The platform includes three sets of systems, which are battery-core development and production data systems, battery pack research and development production data

Get Started

Towards the lithium-ion battery production network:

Jul 1, 2022 · To remedy this, we deploy a global production network (GPN) approach that highlights the increasing intersection of battery manufacturing with the automotive and power

Get Started

Comprehensive analysis of lithium battery ladder utilization

Jun 27, 2019 · Profitable: The use of lithium batteries for ladder utilization and resource recycling can still be commercialized, because in recent years, the automotive industry has been heavily

Get Started

Dynamic lithium battery ladder use technology: difficult

Mar 22, 2025 · The platform includes three sets of systems, which are battery-core development and production data systems, battery pack research and development production data

Get Started

Ultimate Guide to Equipment for Lithium Battery Assembly

Jan 23, 2025 · Lithium battery assembly equipment refers to the machinery and tools used in the production and assembly of lithium-ion batteries. This equipment is essential for ensuring the

Get Started

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Festo offers high-precision automation components for battery manufacturing with pneumatic and electric actuators, valves, and handling systems to improve electrode coating,

Get Started

LITHIUM-ION BATTERY CELL PRODUCTION PROCESS

Apr 22, 2025 · Recent technology developments will reduce the material and manufacturing costs of lithium-ion battery cells and further enhance their performance characteristics. With the help

Get Started

Ladder electrodialysis: Efficient up-concentration of lithium

Jan 28, 2025 · High-concentration ladder compartment solution disrupted the hydration layer of ions during the ED process. The development of lithium extraction technology from salt lakes

Get Started

Current and future lithium-ion battery

Apr 23, 2021 · Here in this perspective paper, we introduce state-of-the-art manufacturing technology and analyze the cost, throughput, and energy

Get Started

Dynamic lithium battery ladder use technology: difficult

The platform includes three sets of systems, which are battery-core development and production data systems, battery pack research and development production data systems, battery packs

Get Started

Advanced New Energy Lithium Battery PACK

Discover the state-of-the-art automated assembly production line system for lithium battery packs, designed for new energy applications. This 16-meter

Get Started

From Raw Materials to Finished Product: The

Nov 10, 2024 · In the lithium-ion battery pack production plant, there is a vast amount of lithium battery science to know, combined with the huge

Get Started

Dynamic lithium battery recycling ladder utilization depth

Aug 19, 2025 · And the recovered lithium ion battery is subjected to technical extraction, and many materials can be used for secondary use. The recycling of the dynamic lithium-ion

Get Started

Sustainable battery manufacturing in the future

Oct 11, 2023 · Lithium-ion battery manufacturing is energy-intensive, raising concerns about energy consumption and greenhouse gas emissions amid surging global demand. New

Get Started

The most comprehensive analysis of ladder utilization and

Apr 8, 2022 · Sir, you can summarize the following four points: the national ministries and commissions advocate the first step-by-step utilization, and then conduct resource recovery;

Get Started

Power cell "ladder utilization" has become a high-frequency

Jul 30, 2019 · Zhangchunyu, director of the second division of the BYD Battery Group, pointed out that at this stage, BYD is taking the example of a comprehensive recovery of lithium iron

Get Started

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Get Started

Lithium‐based batteries, history, current status,

Oct 7, 2023 · The operational principle of the rechargeable battery is centered on a reversible redox reaction taking place between the cathode (positive

Get Started

Li Jianhao: Decomited Lithium Battery Reservoir Ladder

Mar 28, 2025 · المحدودة was invited to discuss the future of energy storage and development with nearly 400 industrial studies. Li Jinchen, general manager of the company, delivered a speech

Get Started

Several major powered lithium battery factory ladder

The recycling process of the power lithium-ion battery is currently important for power lithium-ion battery manufacturers using electric vehicle manufacturers'' sales networks, recycling waste

Get Started

Li Jianhao: Decomited Lithium Battery Reservoir Ladder Using

May 27, 2025 · iFlowPowerToday, my report is the "decommissioning dynamic lithium-ion battery reservoir ladder utilization solution and example analysis". Let me say a few questions, this

Get Started

Dynamic lithium-ion battery ladder utilization and recycling:

May 27, 2025 · After the product is eliminated, it will be used in the field of clean power, and then used for Home energy storage. Swums Technology combines dynamic lithium-ion battery

Get Started

Ladder electrodialysis: Efficient up-concentration of lithium

Jan 28, 2025 · In 2022, China''s lithium battery production reached 23.928 billion units, and it is expected to increase to 38.679 billion units by 2027. Lithium may be obtained from either

Get Started

Dynamic lithium-ion battery ladder utilization and recycling:

Aug 2, 2025 · With the rise of new energy vehicles, the ladder of the dynamic lithium-ion battery has become a problem that must face. In the case of the dynamic lithium-ion battery, the

Get Started

Li-ion cell manufacturing: A look at processes

Jun 10, 2021 · The production of the lithium-ion battery cell consists of three main stages: electrode manufacturing, cell assembly, and cell finishing. Each of

Get Started

In-Depth Analysis of Lithium Battery Manufacturing Processes

Aug 15, 2025 · Explore the detailed process of lithium battery manufacturing 🔋. Learn about materials, production techniques, environmental impacts, and future innovations 🌿.

Get Started

6 FAQs about [Lithium battery production using ladder tools]

What are the production steps in lithium-ion battery cell manufacturing?

Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and cell finishing (formation) based on prismatic cell format. Electrode manufacturing starts with the reception of the materials in a dry room (environment with controlled humidity, temperature, and pressure).

How are lithium ion battery cells manufactured?

The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode manufacturing and cell finishing process steps are largely independent of the cell type, while cell assembly distinguishes between pouch and cylindrical cells as well as prismatic cells.

How are lithium ion batteries processed?

Conventional processing of a lithium-ion battery cell consists of three steps: (1) electrode manufacturing, (2) cell assembly, and (3) cell finishing (formation) [8, 10]. Although there are different cell formats, such as prismatic, cylindrical and pouch cells, manufacturing of these cells is similar but differs in the cell assembly step.

How is the quality of the production of a lithium-ion battery cell ensured?

The production parameter settings are adjusted until the specification values are restored. The products produced during this time are sorted according to the severity of the error. In summary, the quality of the production of a lithium-ion battery cell is ensured by monitoring numerous parameters along the process chain.

How can a local battery manufacturing system help a battery plant?

Local manufacturers will scale up and cover the entire machinery for a battery plant through collaborations, from producing electrodes to the final cell formation. Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system.

What are the benefits of lithium ion battery manufacturing?

The benefit of the process is that typical lithium-ion battery manufacturing speed (target: 80 m/min) can be achieved, and the amount of lithium deposited can be well controlled. Additionally, as the lithium powder is stabilized via a slurry, its reactivity is reduced.

Related Articles

-

How long does it usually take to charge a lithium battery for electric tools

How long does it usually take to charge a lithium battery for electric tools

-

Cylindrical lithium battery production in Nicosia

Cylindrical lithium battery production in Nicosia

-

Produce 12v40ah battery pack using lithium battery

Produce 12v40ah battery pack using lithium battery

-

Lithium battery container production line manufacturer

Lithium battery container production line manufacturer

-

Cylindrical lithium battery production battery pack

Cylindrical lithium battery production battery pack

-

Home energy storage lithium battery production

Home energy storage lithium battery production

-

Tripoli lithium battery station cabinet production line

Tripoli lithium battery station cabinet production line

-

Energy Storage ESS Base Station Lithium Battery Production

Energy Storage ESS Base Station Lithium Battery Production

-

Bridgetown Tools Lithium Battery Price

Bridgetown Tools Lithium Battery Price

-

Energy storage lithium battery manufacturer quotation list

Energy storage lithium battery manufacturer quotation list

Commercial & Industrial Solar Storage Market Growth

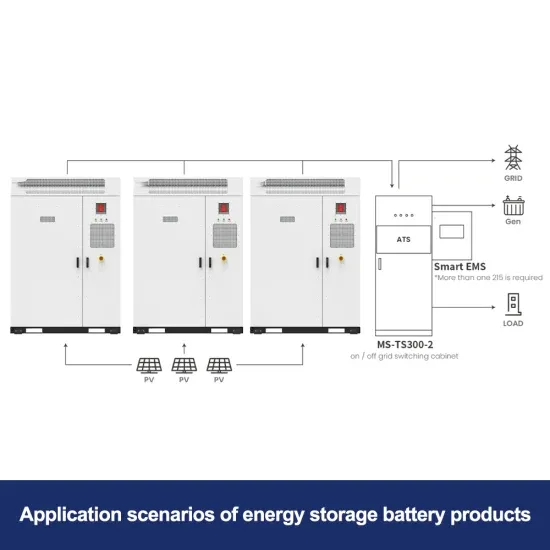

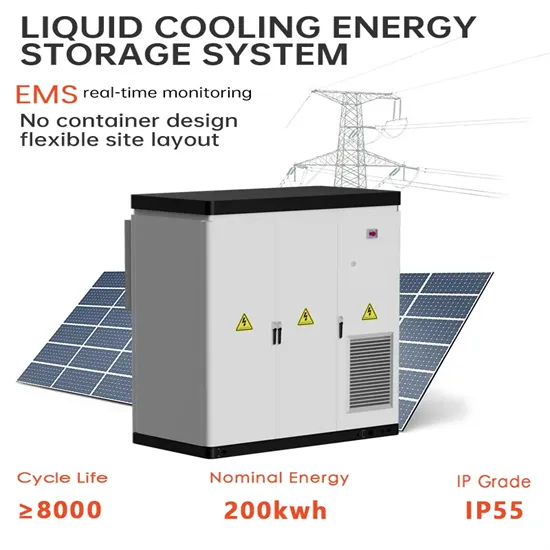

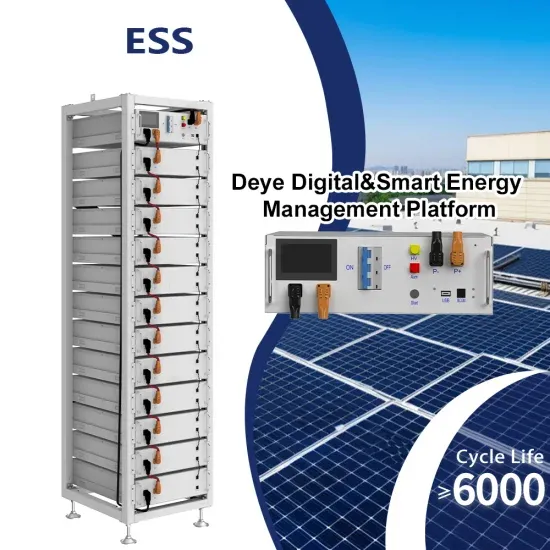

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.