(Infographics #3) Battery Making at a Glance

Jun 14, 2023 · (Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

Get Started

Lithium-ion Cylindrical Cell Manufacturing Process

Jul 25, 2023 · Proper recycling of lithium-ion batteries is important to reduce environmental pollution and conserve natural resources. In conclusion, the

Get Started

探秘圆柱锂电池PACK生产线:从电芯到能源模组的

Mar 24, 2025 · The cylindrical lithium battery PACK production line is the "unsung hero" of the new energy revolution, and Chintiyan (zbqt) Energy is its

Get Started

Square, Cylindrical, Soft Pack: Analysis of Manufacturing

Jun 10, 2025 · In the new energy era, lithium batteries, as the core power and storage units, are of undeniable importance. Among the many characteristics of lithium batteries, the packaging

Get Started

Cylindrical battery pack – design and structure

Jul 8, 2023 · Basic structure of cylindrical battery pack In the cylindrical battery pack design, the battery pack structure is various. It is mainly determined

Get Started

Cylindrical lithium battery: mature production process, high

May 29, 2015 · Production technology of cylindrical lithium battery is mature, the cost of battery pack assembly is low, battery yield and battery consistency is high. Due to the large heat

Get Started

Automotive battery pack manufacturing – a review of battery

Mar 1, 2020 · Automotive battery packs used for electromobility applications consist of a large number of individual battery cells that are interconnected. Interconnection of the battery cells

Get Started

Automatic Cylindrical Lithium

Discover our state - of - the - art fully automatic cylindrical lithium - battery pack production line. It offers unparalleled automation for maximum efficiency,

Get Started

Lithium Battery Production Line,Lithium Battery

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995,Lithium battery production line,Lithium battery lab pilot plant,battery

Get Started

Li Ion Battery Making Line,Li Ion Battery Making

Tmax is a comprehensive company that integrates the production of the Li Ion Battery Making Equipment,Li Ion Battery Production Machine. We are

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

Advanced Automatic Production Line for Large/Small Cylindrical

1: Keywords: Automated assembly line, multi-type battery production, laser welding, energy storage. 2: Introduction: This production line is mainly used for the post-application process of

Get Started

Advanced Lithium Battery Manufacturing Capabilities

Our automated small cylindrical pack assembly is built for volume, speed, and reliability — perfect for electronics, medical, and aerospace applications that demand compact power. Need

Get Started

EV Car Battery Assembly,Electric Bike Battery Assembly

Battery Pack Making Machine 2 in 1 for 18650/26650/32650 Lithium Battery Cells Sorting and Insulation Paper Sticking High Quality Automatic Double Side Lithium Battery Cell Spot

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process

Get Started

Cylindrical Battery Pack Machine: The Precision Engine

Feb 20, 2025 · A cylindrical battery pack machine is a specialized piece of equipment designed for the automated assembly of cylindrical battery cells into battery packs. These machines are

Get Started

18650 Battery Production Machine,Cylindrical

LiFePO4 Lithium Cylindrical Battery Pack Assembly Equipment Machine Line Fully Automatic Lithium-Ion Cylindrical Cell Production Line For All Types

Get Started

Lithium Battery PACK Production Line Processes

Here is an overview of the Lithium Battery PACK line: Cell Types. Cells are the basic units that make up the battery pack, mainly divided into: Prismatic Cells:

Get Started

The Production Process of Cylindrical Lithium

Mar 8, 2025 · Uncover the detailed production process of cylindrical lithium - battery packs. Learn about key steps like cell selection, grouping, module assembly, BMS integration, and more.

Get Started

MAZDA NEWSROOM|Mazda to build Module Pack Plant for Cylindrical Lithium

Jan 6, 2025 · Mazda to build Module Pack Plant for Cylindrical Lithium-ion Batteries for Automotive Use in Iwakuni City, Yamaguchi Prefecture HIROSHIMA, Japan - Mazda Motor

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated

Discover our advanced cylindrical lithium battery production line designed for manufacturing 18650, 21700, and other cylindrical battery models. Our fully automated equipment covers

Get Started

Li-ion Cylindrical – Alium Batteries

Aug 16, 2025 · Lithium-ion Battery Manufacturing As a professional Lithium Iron Battery manufacturer, Alium has manufacturing centers for batteries and

Get Started

32140 33140 Cylindrical Lithium Ion Battery Pack

Cylindrical lithium battery pack is widely used in power tools, smart homes, electric vehicles, photovoltaic energy storage, intelligent lighting, mobile

Get Started

Battery Manufacturing Process: Materials,

Jul 3, 2024 · The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units. This

Get Started

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Here we summarize the cylindrical battery types, capacity, voltage, etc., so you can have a more comprehensive understanding of

Get Started

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · Among the many characteristics of lithium batteries, the external form of packaging shape actually contains complex technical considerations and process logic. The

Get Started

【New message】Innovative Polymer Battery Solutions

GeB: Your dedicated cylindrical lithium battery manufacturer with 16 years of focus. We provide innovative custom solutions for your unique power requirements.

Get Started

Large and Small Cylindrical PACK Automated

Automated assembly line, cylindrical battery production, laser welding, energy storage. 2:Introduction: This production line is mainly used for the back-end

Get Started

Battery Pack Automated Assembly Production Line

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique

Get Started

Batterymaking : Lithium Ion Battery

Tmax is a battery manufacturing equipment and Li ion battery materials supplier with over 20 years of Lithium Ion battery industry experience and professional

Get Started

Lithium Battery Equipment | Battery Manufacturing Machines | Battery

Commercial manufacturing and R&D lithium battery equipment solutions,and battery assembly equipment manufacturers. Vast selection of in stock battery manufacturing machines to

Get Started

Cylindrical Cell manufacturing line

Apr 11, 2025 · A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries. It combines specialized machinery, automation

Get Started

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The speech delivered information on cylindrical batteries currently being developed by LG Energy Solution. Here''s what Kwan-soo Lee working

Get Started

Cylindrical Cell manufacturing Plant

Apr 18, 2025 · Understanding the Cylindrical Cell Manufacturing Plant:Driving Mass Production of High-Quality Batteries The Cylindrical Cell Manufacturing Plant is a large-scale industrial

Get Started

The production of lithium-ion cells

Jan 25, 2023 · There are, however, other formats, such as the 2170 or, again, the one most recently adopted by Tesla, the pioneer of lithium batteries for electric

Get Started

6 FAQs about [Cylindrical lithium battery production battery pack]

What is a lithium battery pack?

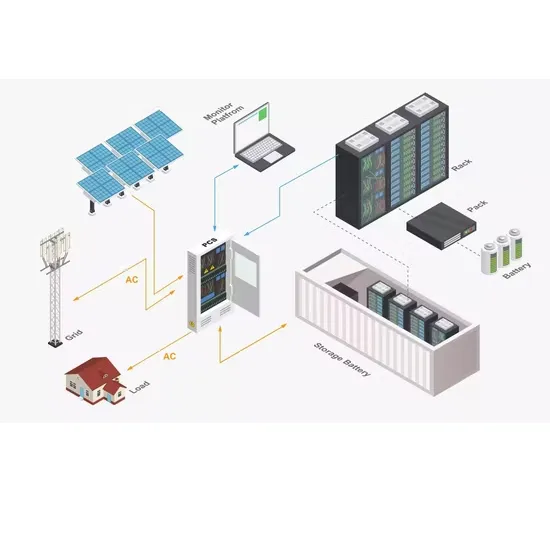

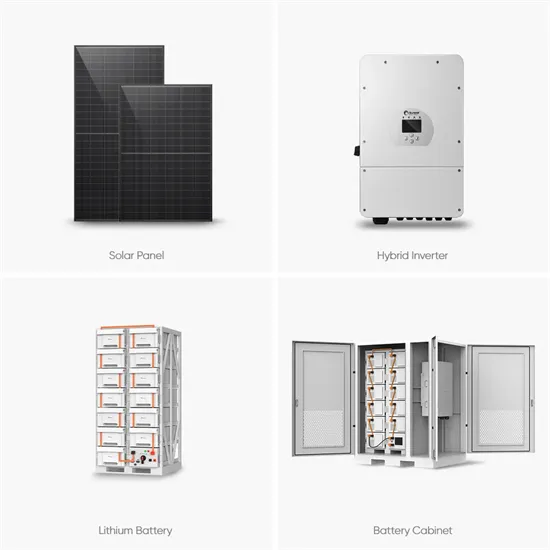

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What are the production processes of a battery pack?

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

What are the components of a battery pack?

Busbars and Soft Connections: For electrical connections between cells. Protection Board: Includes the Battery Management System (BMS), responsible for battery protection and monitoring. Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices.

Why should you choose our automated battery pack assembly line?

Our automated battery pack assembly line is highly standardized and suitable for over 90% of cylindrical battery products on the market. It features unique double-sided cross spot welding equipment for one-time welding, reducing costs and simplifying ope

What is a battery test equipment?

Environmental Test Equipment: For testing the environmental adaptability of batteries. Aging Test Equipment: To assess battery life and stability. BMS Test Equipment: For testing the functions and performance of the battery management system. These devices ensure that the lithium battery PACK meets performance and safety standards.

Related Articles

-

Cylindrical lithium battery production in Nicosia

Cylindrical lithium battery production in Nicosia

-

Main points for lithium battery pack production

Main points for lithium battery pack production

-

Nanya cylindrical lithium battery pack

Nanya cylindrical lithium battery pack

-

French lithium battery pack wholesale

French lithium battery pack wholesale

-

Congo Lithium Battery Production Company

Congo Lithium Battery Production Company

-

Lithium battery pack balancing time

Lithium battery pack balancing time

-

El Salvador low rate lithium battery pack

El Salvador low rate lithium battery pack

-

How many times should the lithium battery pack be balanced

How many times should the lithium battery pack be balanced

-

Poor resistance of lithium battery pack

Poor resistance of lithium battery pack

-

Juba 12v lithium battery pack

Juba 12v lithium battery pack

Commercial & Industrial Solar Storage Market Growth

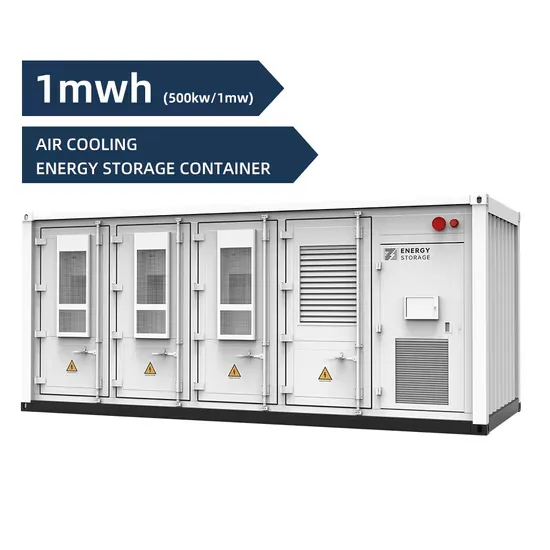

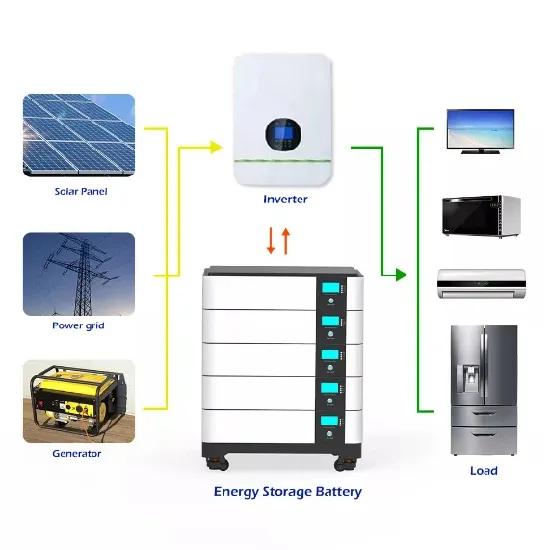

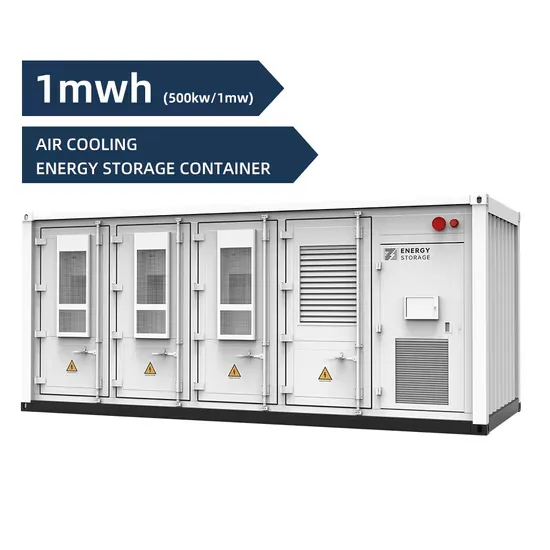

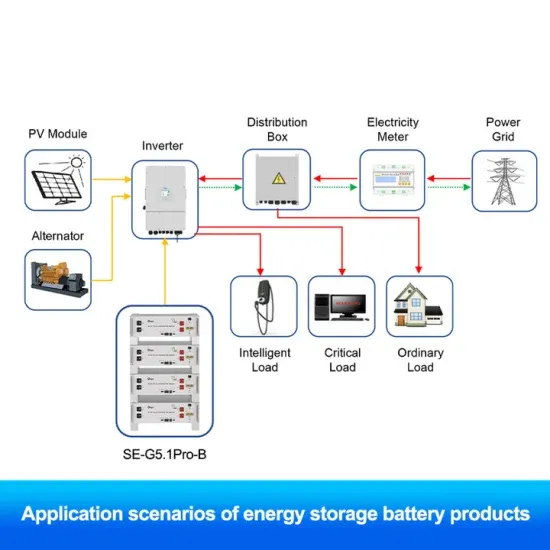

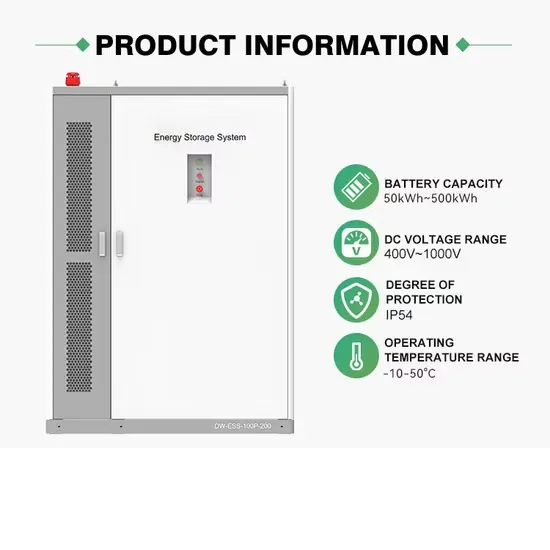

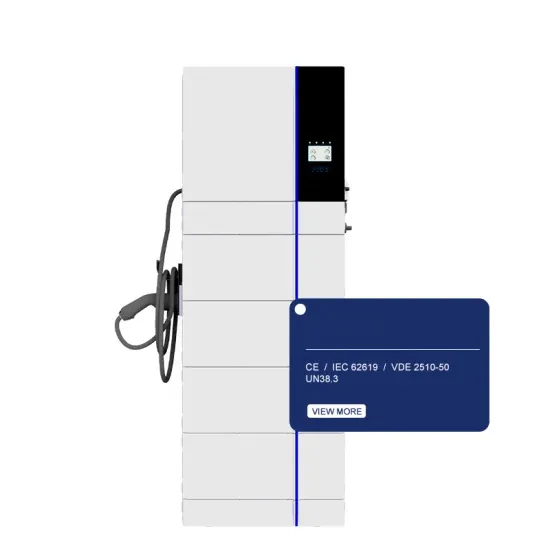

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.