Current and future lithium-ion battery manufacturing

Apr 23, 2021 · LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature technologies have been transferred to current state-of

Get Started

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Here we summarize the cylindrical battery types, capacity, voltage, etc., so you can have a more comprehensive understanding of

Get Started

Li-ion Cylindrical – Alium Batteries

Aug 16, 2025 · Lithium-ion Battery Manufacturing As a professional Lithium Iron Battery manufacturer, Alium has manufacturing centers for batteries and

Get Started

Nicosia Energy Storage Lithium Battery Cluster: Powering the

But here''s the kicker – intermittency issues still cause 17% of potential green energy to go unused [3]. That''s where the Nicosia lithium battery cluster comes in, offering storage capacities

Get Started

Li-ion Cylindrical – Alium Batteries

Aug 16, 2025 · With a highly automated cylindrical battery cell production line and a PACK flexible automated production line, with excellent cell and PACK

Get Started

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Get Started

Cylindrical Cell manufacturing Plant

Apr 18, 2025 · Understanding the Cylindrical Cell Manufacturing Plant:Driving Mass Production of High-Quality Batteries The Cylindrical Cell Manufacturing Plant is a large-scale industrial

Get Started

Which Lithium Battery Company is Good in Nicosia? Your

You''re a solar energy startup in Nicosia trying to power smart homes across Cyprus. Your secret weapon? Lithium batteries that last longer than your morning Greek coffee. But which lithium

Get Started

圆柱形锂离子电池的设计、特性和制造——概述,Batteries

Jun 3, 2023 · Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview Battery cells are the main components of a battery system for electric vehicle

Get Started

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · What''s the difference between pouch, prismatic, and cylindrical cells in lithium batteries? Read our guide to find the right battery cell type for your system.

Get Started

Lithium-ion Cylindrical Cell Manufacturing Process

Jul 25, 2023 · Proper recycling of lithium-ion batteries is important to reduce environmental pollution and conserve natural resources. In conclusion, the

Get Started

Cylindrical Cell manufacturing line

Apr 11, 2025 · What is a Cylindrical Cell Manufacturing Line? A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries.

Get Started

Eve Energy plant in Malaysia sees 1st battery

Feb 17, 2025 · Eve Energy has started production at its Malaysian plant, marking a milestone for the Chinese lithium battery maker in overseas markets. The

Get Started

MAZDA NEWSROOM|Mazda to build Module Pack Plant for Cylindrical Lithium

Jan 6, 2025 · Mazda to build Module Pack Plant for Cylindrical Lithium-ion Batteries for Automotive Use in Iwakuni City, Yamaguchi Prefecture HIROSHIMA, Japan - Mazda Motor

Get Started

(PDF) Lithium-ion Battery Cell Production

Feb 6, 2019 · Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

Get Started

Nicosia lithium battery energy storage

Here, we focus on the lithium-ion battery (LIB), a "type-A" technology that accounts for >80% of the grid-scale battery storage market, and specifically, the market-prevalent battery

Get Started

Top 10 Lithium Battery Companies Dominate

Dec 9, 2024 · Discover the 2024 top 10 lithium battery companies by EV battery installations. Explore industry leaders driving innovation and sustainability.

Get Started

【New message】Innovative Polymer Battery Solutions

When your application demands precision, reliability, and a battery built specifically for its needs, trust the 16 years of focused expertise at GeB. Contact GeB today to explore how our custom

Get Started

The production of lithium-ion cells

Jan 25, 2023 · Correct assembly of the cells that make up a lithium battery, whether such cells are prismatic, cylindrical or of the pouch type, is therefore

Get Started

Future of Lithium-Ion Batteries: Cylindrical,

Apr 18, 2025 · The cylindrical lithium-ion battery boasts mature production technology with high yields. Models like 14650, 17490, 18650, 21700, and

Get Started

(Infographics #3) Battery Making at a Glance

Jun 14, 2023 · (Infographics #3) Battery Making at a Glance The manufacturing process of lithium-ion batteries consists largely of 4 big steps of electrode

Get Started

Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Get Started

PRODUCTION PROCESS OF A LITHIUM-ION

Apr 19, 2023 · Cost‐savings in lithium‐ion battery production are crucial for promoting widespread adoption of Battery Electric Vehicles and achieving

Get Started

Complete Guide to Cylindrical Cell

Apr 7, 2024 · Part 1. Cylindrical cell history Cylindrical cells have a long history. Since the introduction of dry batteries, batteries have been cylindrical in

Get Started

The Production Process of Cylindrical Lithium

Mar 8, 2025 · Uncover the detailed production process of cylindrical lithium - battery packs. Learn about key steps like cell selection, grouping, module assembly, BMS integration, and more.

Get Started

Cylindrical Cell Manufacturing

Jun 20, 2025 · Cylindrical Cell Manufacturing: A Detailed OverviewLith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the

Get Started

BATTERY CELL PRODUCTION IN EUROPE: STATUS QUO

Jul 1, 2024 · Battery cell production Europe nd battery market are also becoming noticeable in Europe. In Europe, ACC, AESC, CATL, LG Energy Solution, Northvolt, Samsung SDI and SK

Get Started

Full Explanation of Lithium Battery Production

Aug 9, 2024 · What makes lithium-ion batteries so crucial in modern technology? The intricate production process involves more than 50 steps, from electrode

Get Started

6 FAQs about [Cylindrical lithium battery production in Nicosia]

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

How many times does a lithium phosphate battery cycle?

The lithium iron phosphate high-power LFP cell cycles more than 7000 times. Power-type lithium iron phosphate battery cells cycle more than 5000 times. NCM cells cycle more than 1500 times. LiFePO4 battery cells with more than 12 years calendar life. NCM battery with more than 10 years calendar life.

What is the potential for Battery Integration Technology?

However, the potential for battery integration technology has not been depleted. Increasing the size and capacity of the cells could promote the energy density of the battery system, such as Tesla 4680 cylindrical cells and BMW 120 Ah prismatic cells.

Are lithium-ion batteries a viable energy storage solution?

Lithium-ion batteries (LIBs) have become one of the main energy storage solutions in modern society. The application fields and market share of LIBs have increased rapidly and continue to show a steady rising trend. The research on LIB materials has scored tremendous achievements.

Related Articles

-

Cylindrical lithium battery production battery pack

Cylindrical lithium battery production battery pack

-

Stacked lithium battery cylindrical battery

Stacked lithium battery cylindrical battery

-

Croatia cylindrical lithium battery customization

Croatia cylindrical lithium battery customization

-

Cylindrical lithium battery expansion

Cylindrical lithium battery expansion

-

What is the function of cylindrical lithium battery

What is the function of cylindrical lithium battery

-

Azerbaijan cylindrical lithium battery customization

Azerbaijan cylindrical lithium battery customization

-

Cylindrical lithium battery into the box

Cylindrical lithium battery into the box

-

Cylindrical lithium battery automatic charging equipment

Cylindrical lithium battery automatic charging equipment

-

Lithium battery wholesale cylindrical

Lithium battery wholesale cylindrical

-

Italian Milan cylindrical lithium battery millivolt

Italian Milan cylindrical lithium battery millivolt

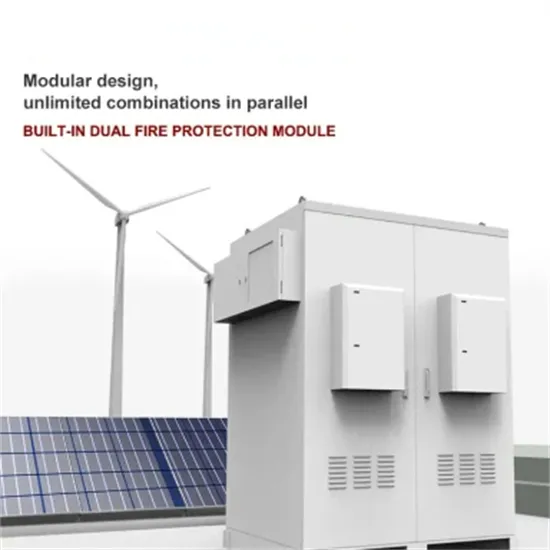

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.