EV Battery Smart Factory Solutions

Lyric Robot specializes in the customization and R&D, manufacturing and sales of high-end, intelligent and automated equipment. Lyric Robot is committed to providing integrated

Get Started

CN109693936A

The present invention relates to technical field of electronic communication, and in particular to a kind of the cylindrical lithium battery automatic charging device and method of wearable smart

Get Started

5V 50A 8-Channel Large Cylindrical Prismatic Electric Car Lithium

Oct 21, 2024 · 5V 50A 8-Channel Large Cylindrical Prismatic Electric Car Lithium-Ion Battery Cell Automatic Cycle Charging and Discharging Tester Analyzer, Find Details and Price about

Get Started

Lithium Battery Production Line,Lithium Battery

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995,Lithium battery production line,Lithium battery lab pilot plant,battery

Get Started

Lithium Battery Production & Intelligent Equipment | Mikrouna

Founded in 1998, Mikrouna is a leading high-tech enterprise specializing in vacuum automation and intelligent equipment. Holding over 180 patents, Mikrouna offers isolated glove boxes,

Get Started

Cylindrical Prismatic Pouch Li-ion Cell Automatic Cycle Charging

Lithium Battery Charge Discharge Testing and Balance Maintenance Machine DT50W-16 can be applicable for the capacity test, auto-cycle charge and discharge test, capacity grading and

Get Started

32140 33140 Cylindrical Lithium Ion Battery Pack

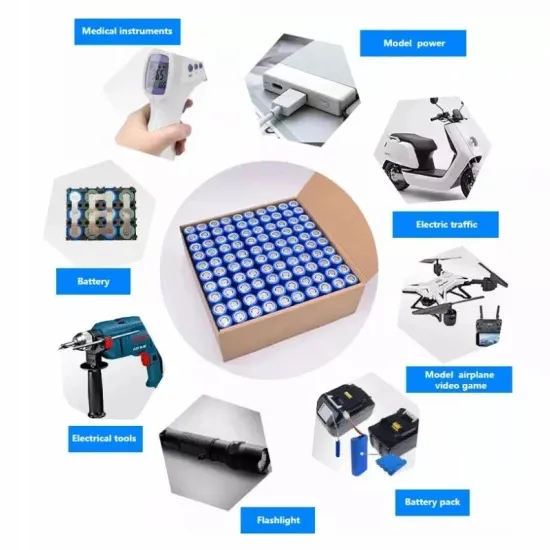

Cylindrical lithium battery pack is widely used in power tools, smart homes, electric vehicles, photovoltaic energy storage, intelligent lighting, mobile

Get Started

512 Channels 5V 5A Lithium Battery Cylindrical

512 Channels 5V 5A Lithium Battery Cylindrical Cell Charging Discharging Testing Machine Description Li-ion battery charging and discharging test

Get Started

Cylindrical Batteries Charging And Discharging Machine

Cylindrical Batteries Charging And Discharging Machine Cylindrical Batteries Charging And Discharging Machine Single Channels Battery Charge and Discharge Machine8 Channels

Get Started

The 5 Best Battery Cyclers of 2025

This is where battery cyclers, also known as battery analyzers or testers, come into play. These devices simulate the real-world charge and discharge cycles

Get Started

18650 Cylindrical Lithium Battery Fully Automatic Battery

18650 Cylindrical Lithium Battery Fully Automatic Battery Pack Production Line Equipment 1. Suitable for batteries: The entire production line is suitable for 18650 21650 21700 26650

Get Started

Cylindrical Battery Helium Charging Equipment, Factory

Highlight cylindrical battery laser welding equipment battery automatic production line cylindrical lithium battery laser welding equipment Condition New Compatible battery 50AH~280AH

Get Started

BK-3256L/5 5V5A Lithium Battery Cylindrical Cell

BK-3256L/5 256CH 5V5A Lithium ion battery automatic charge discharge test and formation grading machine Model:BK-3256L/5 Ⅰ.Equipment compose: The

Get Started

Automatic Cylindrical Pack Assembly Production Line

The aging cabinet is mainly used for testing the charging and discharging cycle of finished lithium batteries.30V 10A charge 20A discharge/ 70V 5A 10A/ 70V 10A 20A/ 85V 10A 20A/ 100V 10A

Get Started

Automatic Cylindrical Lithium Battery Sorter Machine Industrial Equipment

The company now has a variety of specifications and models of machinery and equipment, various series of cylindrical lithium battery paste accessories equipment, cylindrical lithium

Get Started

Li-ion Cylindrical – Alium Batteries

Aug 16, 2025 · Lithium-ion Battery Manufacturing As a professional Lithium Iron Battery manufacturer, Alium has manufacturing centers for batteries and

Get Started

Winnergy 18650 Cylindrical Lithium Battery Pack

Jul 2, 2025 · Turnkey Solution for 18650 32700 Lithium Battery Pack Charging Sorting Sticking Welding Testing Machines for Semi automatic Production

Get Started

Cylindrical Prismatic Pouch Li-ion Cell Automatic

Jul 6, 2025 · Lithium Battery Charge Discharge Testing and Balance Maintenance Machine DT50W-16 can be applicable for the capacity test, auto-cycle charge

Get Started

Top 10 lithium battery production equipment

Jul 29, 2023 · In the field of lithium battery intelligent manufacturing, the equipment is suitable for square aluminum case lithium batteries, soft

Get Started

18650 Battery Pack Assembly Machine,18650

High-Efficiency Semi-Automatic Cylindrical Pack Production Plant Detailed flowchart for Li-ion battery pack assembling with Cylindrical cells Important

Get Started

Lithium Battery Pack Equipment New Energy Battery Pack Automatic

Cylindrical lithium battery PACK equipment New energy lithium battery energy storage pack automatic line equipment manufacturers cylindrical battery packaging production line cell

Get Started

Cylindrical lithium battery automatic tray type forming equipment

The overall appearance of the equipment is sky blue, and the color of the tray is black with PP flame retardant material 14. Each group of the equipment is installed with a fixed tray that can

Get Started

Shanghai ShiNeng Electrical Equipment Co., Ltd.

Integrate constant current, constant voltage, and automatic shutdonw technologies into the entire charging process, It has the advantages of high degree of automation, easy operation, High

Get Started

Batterymaking : Lithium Ion Battery

Tmax is a battery manufacturing equipment and Li ion battery materials supplier with over 20 years of Lithium Ion battery industry experience and professional

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated Equipment

Discover our advanced cylindrical lithium battery production line designed for manufacturing 18650, 21700, and other cylindrical battery models. Our fully automated equipment covers

Get Started

BK-3512/E 5V5A 18650 21700 26650 Lithium

This equipment capable implement 5V5A 18650 21700 26650 lithium battery cell charge discharge testing,capacity and sorting testing,current,voltage

Get Started

Cylindrical Lithium Battery Pack Assembly Plant Equipments

Tmax is a professional Cylindrical Lithium Battery Pack Assembly Plant Equipments for EV Bike/Energy Storage/ Solar Light Battery Assembly,Battery Pack Assembly Plant supplier from

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated Equipment

The cylindrical lithium battery production line is designed for manufacturing 18650, 21700, and other models of cylindrical lithium-ion batteries. This production line covers the entire process

Get Started

Cycle Performance / Formation Testing for

High accuracy lithium battery charging and discharging formation equipment,lithium battery cycle life tester,automated testing solution for lithium battery

Get Started

Automatic Cylindrical Cell Insulation Paper

Automatic Cylindrical Cell Insulation Paper Sticking Machine Lithium Battery Pasting Barley Paper Equipment Contact Person:Louis Yang Email:

Get Started

Battery Pack Assembly Equipment Manufacturer, Battery Test Equipment

Founded in 2011, WinAck Battery has always focused on the R&D and production of battery pack assembly equipment and battery testing equipment. More professional, we can provide

Get Started

Battery Pack Assembly Machine | Battery Pack Manufacturers | Battery

Tmax is the most professional battery pack manufacturers,we offer high quality battery pack assembly machine and battery assembly machine for battery research and manufacturing.

Get Started

Energy Storage Battery Charging And

Jul 1, 2025 · SMALL CYLINDRICAL LITHIUM PACK AUTOMATED ASSEMBLY LINE APOLLO INVERTER WITH ESS B SERIES LiFePO4 BATTERY lithium

Get Started

5 FAQs about [Cylindrical lithium battery automatic charging equipment]

What is a cylindrical lithium-ion battery?

A cylindrical lithium-ion battery is a type of lithium-ion battery with a cylindrical shape using a metal can as its packaging material.

What are the different types of lithium-ion battery cells?

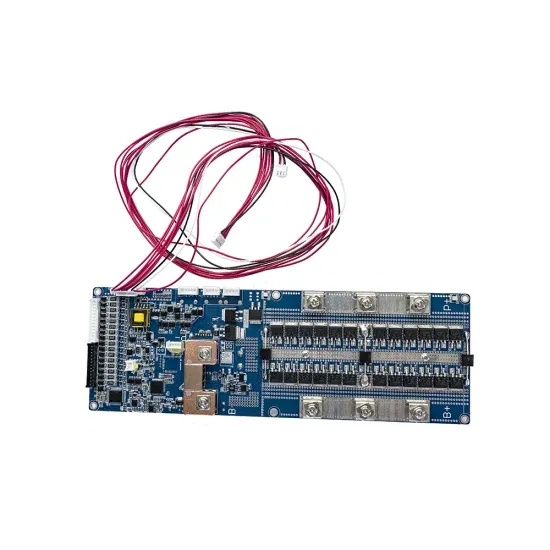

Among the various types of lithium-ion battery cells, LCO (Lithium Cobalt Oxide), NMC (Nickel Manganese Cobalt), and LFP (Lithium Iron Phosphate) are some of the most commonly used chemistries, each offering unique advantages and trade-offs in terms of structure, performance, cost, and manufacturing requirements.

What are lithium-ion batteries used for?

In the rapidly evolving world of energy storage, lithium-ion batteries have become the dominant choice for applications ranging from electric vehicles (EVs) to portable electronics.

What is czb5c series Charger?

The CZB5C series charger organically combines magnetic leakage transformer, silicon controlled rectifier technology and microcomputer control technology to achieve optimized Wsa+Pulse charging characteristics.. The CZC7 series automatic charger has two models:CZC7 with fixed charging parameters and CZC7A with adjustable charging parameters...

Are Chargers & dischargers qualified export products?

Chargers and dischargers have been confirmed as qualified export products by the national commodity inspection department and exported to more than a dozen countries and regions such as Europe, America, Australia, and Southeast Asia. A self-built warehouse with sufficient inventory of conventional parts further shortens the customization cycle.

Related Articles

-

Algiers cylindrical lithium battery equipment manufacturing

Algiers cylindrical lithium battery equipment manufacturing

-

Colombia cylindrical lithium battery equipment

Colombia cylindrical lithium battery equipment

-

Ukrainian CRRC lithium battery energy storage equipment

Ukrainian CRRC lithium battery energy storage equipment

-

Moscow lithium battery cylindrical battery

Moscow lithium battery cylindrical battery

-

Bamako cylindrical lithium battery supplier

Bamako cylindrical lithium battery supplier

-

Does the lithium iron phosphate battery have a cylindrical shape

Does the lithium iron phosphate battery have a cylindrical shape

-

Nanya cylindrical lithium battery pack

Nanya cylindrical lithium battery pack

-

Cylindrical lithium battery model classification

Cylindrical lithium battery model classification

-

Cost structure of cylindrical lithium iron phosphate battery

Cost structure of cylindrical lithium iron phosphate battery

-

Cylindrical lithium battery expansion

Cylindrical lithium battery expansion

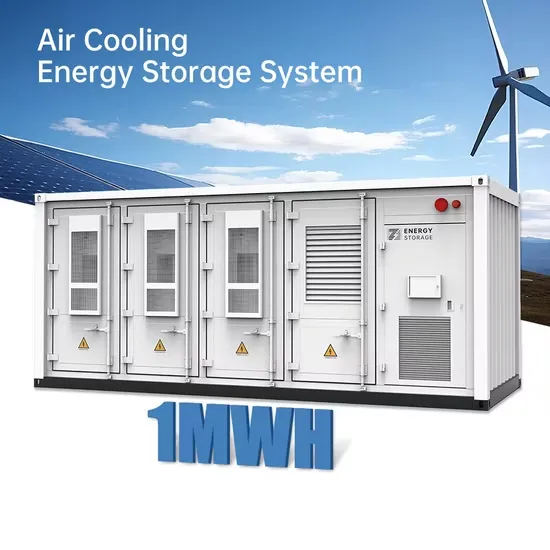

Commercial & Industrial Solar Storage Market Growth

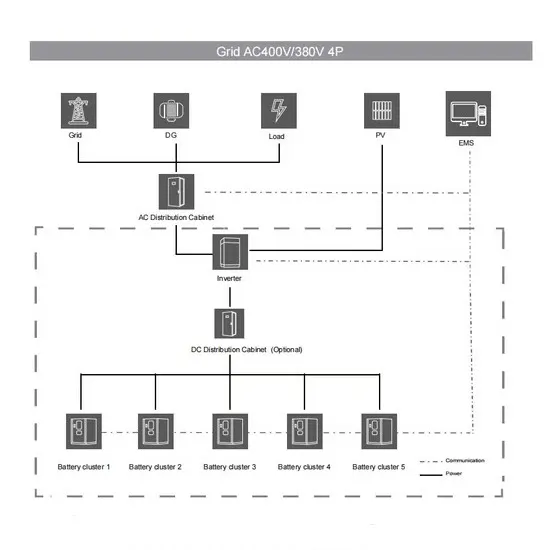

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.