Su-vastika : The future of home energy storage

Sep 2, 2023 · A LiFePO4 cylindrical cell is a type of lithium iron phosphate (LiFePO4) battery that has a cylindrical shape. Cylindrical cells are the most common type of LiFePO4 cell and are

Get Started

BYD Blade Battery: Advantages and

Jul 24, 2025 · BYD blade battery is an innovative battery. Can it really disrupt the EV industry? This guide comprehensively analyzes the Pros and Cons of BYD

Get Started

Breaking Down the Cost of an EV Battery Cell

Jan 6, 2025 · The average cost of EV batteries has fallen by 89% since 2010. What makes up the cost of a single EV battery cell?

Get Started

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

Get Started

Cylindrical vs Prismatic LiFePO4 Battery Cells

Jul 16, 2024 · Lithium Iron Phosphate (LiFePO4) batteries are increasingly popular across various industries, from electric vehicles to renewable energy

Get Started

A Comprehensive Guide to LiFePO4 Cells

Jan 19, 2024 · LiFePO4 cells, short for Lithium Iron Phosphate cells, are a type of rechargeable battery. They belong to the broader family of lithium-ion batteries

Get Started

Pricing phosphates for LFP battery production

As iron phosphate (FePO 4) is the key intermediary between the phosphate and LFP sectors, we developed an analysis to understand the cost structure of

Get Started

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Recent trends indicate a slowdown, including a slight cost increase in LiBs in 2022. This study employs a high-resolution bottom-up cost model, incorporating factors such as

Get Started

The Rise of Lithium Iron Phosphate (LFP): Cost

Nov 30, 2020 · The main cost contributors to a lithium ion battery cell are the cathode, the anode, the separator, and the electrolyte. For LFP, these four

Get Started

Understanding the Differences Between

Mar 18, 2025 · Choosing the right lithium battery cell impacts performance, cost and safety. Cylindrical cells have a stable structure and offer relatively high

Get Started

Cost modeling for the GWh-scale production of modern lithium

We estimate the full, levelized, and marginal cell costs of four distinct cell chemistry combinations, including a nickel-rich cathode combined with either a graphite or silicon-blended graphite

Get Started

The Role of Lithium Iron Phosphate (LiFePO4) in

Apr 18, 2025 · Discover how lithium iron phosphate (LiFePO4) enhances battery performance with long life, safety, cost efficiency, and eco-friendliness.

Get Started

Comparison of Lithium Iron Phosphate (LiFePO₄) Battery Cell

6 days ago · Pouch Cells Structure and Manufacturing: Pouch cells consist of active lithium iron phosphate material encapsulated within a flexible pouch made of polymer and aluminum,

Get Started

Lithium Iron Phosphate

Lithium iron phosphate Lithium iron phosphate, a stable three-dimensional phospho-olivine, which is known as the natural mineral triphylite (see olivine structure in Figure 9 (c)), delivers 3.3–3.6

Get Started

Lithium-Ion 32140 Energy Cells

Lithium Werks'' Lithium Iron Phosphate battery technology offers thermal-stable chemistry, faster charging, consistent output, low capacity loss over time, and

Get Started

Reliable Power: LiFePO4 Battery & LiFePO4 cells

Aug 14, 2025 · Source top-tier lithium iron phosphate solutions from an industry-leading manufacturer. Our A-grade LiFePO4 cells and custom battery packs

Get Started

Investigation on Levelized Cost of Electricity for

Jun 23, 2024 · Given the above background, this paper aims to study the levelized cost of the electricity model for lithium iron phosphate battery energy

Get Started

LiFe-Shenzhen Melasta Battery Co., Ltd

Jul 4, 2023 · LiFePO4 is the formula name of Lithium Iron Phosphate, also known as LFP. The nominal voltages of this battery chemistry are 3.2V. It replaced

Get Started

33140 3.2V 15Ah LiFePO4 Battery Cell for Energy

Experience reliable power and energy independence with the 33140 3.2V 15Ah LiFePO4 battery cell. This high-capacity cylindrical lithium iron phosphate

Get Started

Lithium Iron Phosphate (LiFePO4): A

Nov 20, 2024 · Lithium iron phosphate (LiFePO4) is a critical cathode material for lithium-ion batteries. Its high theoretical capacity, low production cost,

Get Started

Electric vehicle economics: How lithium-ion

Nov 5, 2024 · Electric vehicle economics: How lithium-ion cell costs impact EV prices Lithium prices have fallen significantly, putting the cost of cells at 7.5%

Get Started

Industrial preparation method of lithium iron

Industrial preparation method of lithium iron phosphate (LFP) Lithium iron phosphate (LiFePO4) has the advantages of environmental friendliness, low

Get Started

[LiFePO4 Battery Types] Cylindrical vs. Prismatic

Oct 22, 2024 · LiFePO4 batteries, or lithium iron phosphate batteries, are increasingly recognized for their remarkable safety, longevity, and versatility.

Get Started

Explore LFP Battery Raw Material: LFP Cathode

Jan 30, 2024 · Lithium iron phosphate is an important cathode material for lithium-ion batteries. Due to its high theoretical specific capacity, low manufacturing

Get Started

Lithium batteries fundamentals | Nordkyn Design

Feb 21, 2021 · Lithium Iron Phosphate (LiFePO 4, sometimes also referred to as LFP) and Lithium Titanate Oxide (LTO) are by far the most robust types of

Get Started

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Get Started

What Is the Lithium Iron Phosphate Battery Price?

Jun 17, 2024 · Know about Lithium iron phosphate battery prices from a manufacturing perspective to popular brands. Explore current price per kWh

Get Started

Battery cost forecasting: a review of methods

May 20, 2021 · Within this transformation, battery costs are considered a main hurdle for the market-breakthrough of battery-powered products. Encouraged

Get Started

Lifecycle Cost Analysis of Lithium Iron Phosphate Batteries

Aug 8, 2025 · Battery composition and manufacturing process optimization: Improving the composition and manufacturing process of lithium iron phosphate batteries can significantly

Get Started

6 FAQs about [Cost structure of cylindrical lithium iron phosphate battery]

Do material prices affect the cost structure of a lithium-ion battery cell?

By discussing different cell cost impacts, our study supports the understanding of the cost structure of a lithium-ion battery cell and confirms the model’s applicability. Based on our calculation, we also identify the material prices as a crucial cost factor, posing a major share of the overall cell cost.

How are materials costs of lithium ion batteries calculated?

The breakdown covers 25 categories (e.g., lithium, nickel, graphite), across 10 different battery chemistries (e.g., NCA, NMC, LFP and others, chart below). Materials costs of lithium ion batteries can be calculated by comparing our mass balances above with the costs of different input commodity prices.

What is a lithium ion battery data-file?

This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested. This data-file disaggregates the materials used in lithium ion batteries and their costs.

How much does a lithium ion battery cost?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost, marginal cost and actual pricing). This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested.

What is a battery chemistry cost model?

It calculates battery cell and pack costs for different cell chemistries under a specified production volume within a pre-defined factory layout and production process. The model is frequently used, adapted, or extended by various authors 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18.

How much does a Lib battery cost?

The average LiB cell cost for all battery types in their work stands approximately at 470 US$.kWh −1. A range of 305 to 460.9 US$.kWh −1 is reported for 2010 in other studies [75, 100, 101]. Moreover, the generic historical LiB cost trajectory is in good agreement with other works mentioned in Fig. 6, particularly, the Bloomberg report .

Related Articles

-

Ct200 cylindrical lithium iron phosphate battery

Ct200 cylindrical lithium iron phosphate battery

-

Honiara cylindrical lithium iron phosphate battery

Honiara cylindrical lithium iron phosphate battery

-

Is the cylindrical battery a lithium iron phosphate battery

Is the cylindrical battery a lithium iron phosphate battery

-

Bissau cylindrical lithium iron phosphate battery import

Bissau cylindrical lithium iron phosphate battery import

-

Does the lithium iron phosphate battery have a cylindrical shape

Does the lithium iron phosphate battery have a cylindrical shape

-

Energy storage lithium iron phosphate battery station cabinet for sale

Energy storage lithium iron phosphate battery station cabinet for sale

-

Chad lithium iron phosphate battery pack wholesale

Chad lithium iron phosphate battery pack wholesale

-

How much does a cylindrical lithium battery cost in Tehran

How much does a cylindrical lithium battery cost in Tehran

-

Cote d Ivoire energy storage lithium iron phosphate battery

Cote d Ivoire energy storage lithium iron phosphate battery

-

Lithium iron phosphate battery for base stations

Lithium iron phosphate battery for base stations

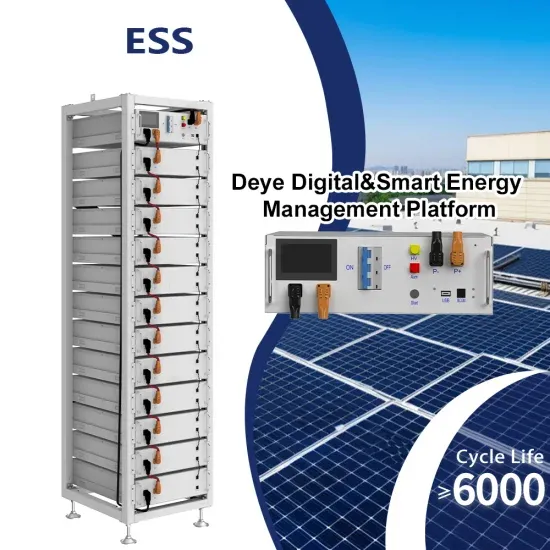

Commercial & Industrial Solar Storage Market Growth

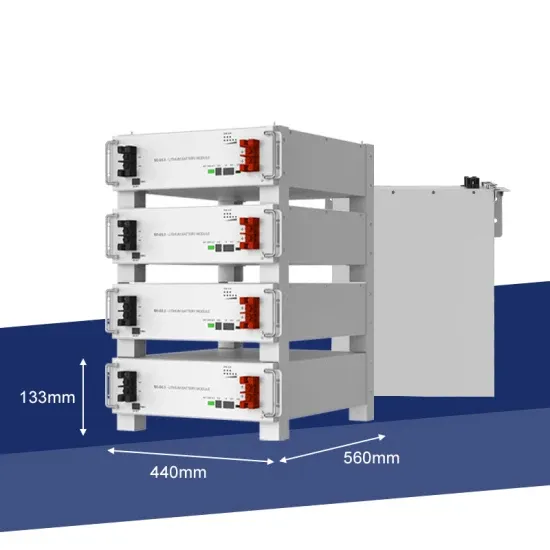

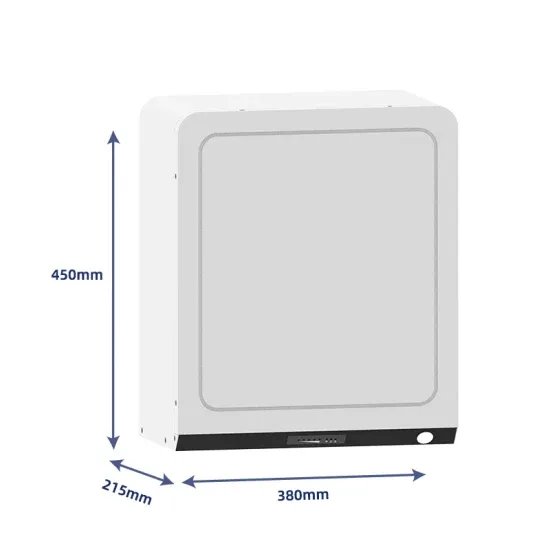

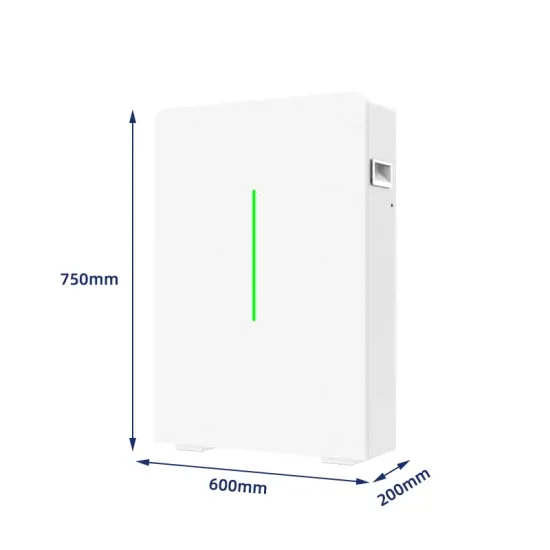

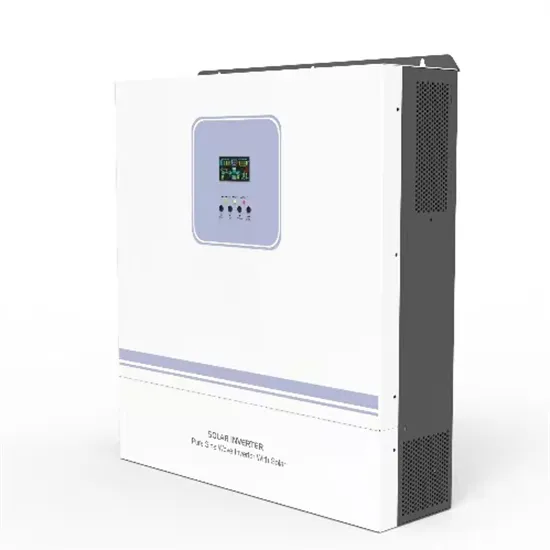

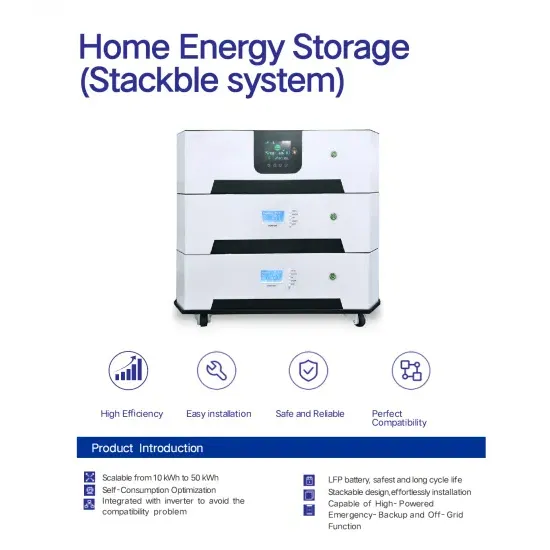

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.