Battery Manufacturing Basics from CATL''s Cell

Jun 13, 2021 · A summary of CATL''s battery production process collected from publicly available sources is presented. The 3 main production stages and 14

Get Started

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · The story of cylindrical lithium-ion battery cells traces back to the 1990s, when researchers pioneered the development of rechargeable lithium

Get Started

Algiers battery welding piece production process

Decoding the Lithium Battery Cell Production Process . In the realm of lithium battery manufacturing, understanding the intricate production process is vital. Let''''s delve into each

Get Started

Inside the World of Battery Cell Manufacturing

Jun 24, 2024 · This guide to battery cell manufacturing explores the process from procurement to final assembly. We also shed light on the trends shaping the

Get Started

Algeria Outlines Three Strategic Pillars to Launch

2 days ago · ️ BY: Dr. Hana Saada Algiers, Algeria | Algeria has set forth a clear roadmap to anchor its ambition of becoming a regional leader in electric

Get Started

Cylindrical battery laboratory manufacturing factory

Our cylindrical battery laboratory manufacturing factory is equipped with advanced equipment and technology for battery development, optimization, large-scale production testing, and validation.

Get Started

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Get Started

(PDF) Lithium-ion Battery Cell Production

Feb 6, 2019 · Abstract The first brochure on the topic "Production process of a lithium-ion battery cell" is dedicated to the production process of the lithium

Get Started

Battery Manufacturing | Bosch Manufacturing Solutions | BMG

5 days ago · With over 15 years of experience in battery manufacturing, we specialize in Cell to Pack Manufacturing and Cell Technology solutions for battery modules and packs. Our

Get Started

LEAD Cylindrical Lithium Battery Manufacturing Turnkey

End-to-end cylindrical Lithium lon battery production Line solutions from LEAD — increasing efficiency, precision, and scalability in battery production.

Get Started

Design, Properties, and Manufacturing of

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim

Get Started

Li-ion Cylindrical – Alium Batteries

Aug 16, 2025 · Lithium-ion Battery Manufacturing As a professional Lithium Iron Battery manufacturer, Alium has manufacturing centers for batteries and

Get Started

Current and future lithium-ion battery

Apr 23, 2021 · LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature technologies

Get Started

Lithium Cell Manufacturing Line

Dec 12, 2024 · Lithium Cell Manufacturing Line: Key to Efficient and Scalable Battery Production A lithium cell manufacturing line is a specialized production facility designed to manufacture

Get Started

18650 Battery Production Machine,Cylindrical

LiFePO4 Lithium Cylindrical Battery Pack Assembly Equipment Machine Line Fully Automatic Lithium-Ion Cylindrical Cell Production Line For All Types

Get Started

Algiers lithium battery cascade utilization equipment

Xingmao Machinery has a service team for Africa Lithium battery recycling and cascade utilization equipment customers, which can provide reliable Lithium battery recycling and cascade

Get Started

EVE Energy and Germany''s KBS sign strategic supply

Apr 10, 2025 · By providing zero-carbon power solutions for high-end European logistics equipment, the two parties will jointly build an industrial ecosystem covering technology R&D,

Get Started

Cylindrical Lithium Battery Production Line: Fully Automated Equipment

Discover our advanced cylindrical lithium battery production line designed for manufacturing 18650, 21700, and other cylindrical battery models. Our fully automated equipment covers

Get Started

Lithium-ion Battery Production

DJK specializes in providing comprehensive solutions for lithium-ion battery (LiB) manufacturing. We offer a wide range of equipment and technologies for

Get Started

Promising prospects for lithium industry development in

Apr 9, 2025 · ALGIERS- Algerian scientific researcher, Prof Karim Zaghib, stressed Tuesday in Algiers the promising prospects for the development of the lithium industry in Algeria, through

Get Started

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · LIB industry has established the manufacturing method for consumer electronic batteries initially and most of the mature technologies have been transferred to current state-of

Get Started

Algeria Lithium Ion Battery Market (2025-2031)

Algeria Lithium Ion Battery market currently, in 2023, has witnessed an HHI of 8936, Which has increased slightly as compared to the HHI of 2823 in 2017. The market is moving towards

Get Started

Digatron Systems

Turn-key production plant for the complete formation and finishing process of Pouch, Cylindrical and Prismatic lithium cells. A kit of machines to build lithium cylindrical cells, from electrode

Get Started

Li-ion Lab Battery Equipment and Battery Assembly Machine

AOT Electronics Technology Co.,LTD was set up as a manufacturer in 2006. AOT has been focused on product development and operations of lithium battery and its surrounding, we

Get Started

Battery Lab Equipment for Lithium-ion Manufacturing | Targray

Aug 18, 2025 · Targray Battery Lab Equipment is supplied to lithium-ion battery developers for the production of various energy storage technologies. Our catalog offers customized high efficient

Get Started

Top Lithium Battery Manufacturers in 2025: Who

Mar 12, 2025 · In 2025, a mix of Chinese, South Korean, and Japanese giants dominate the lithium battery landscape. Companies like CATL, BYD, LG

Get Started

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Get Started

Batterymaking : Lithium Ion Battery

Tmax is a battery manufacturing equipment and Li ion battery materials supplier with over 20 years of Lithium Ion battery industry experience and professional

Get Started

Cylindrical Cell Manufacturing Equipment Solutions | Targray

Aug 16, 2025 · Cylindrical Cell Manufacturing can be broken down into 4 stages: Electrode preparation, Cell assembly, Case formation & sealing, and battery testing.

Get Started

13 Largest Battery Manufacturers In The World

Aug 7, 2025 · We present the largest, most influential battery manufacturers, exploring their market positions & strategies that have enabled them to

Get Started

Related Articles

-

Colombia cylindrical lithium battery equipment

Colombia cylindrical lithium battery equipment

-

Cylindrical lithium battery manufacturing in South Sudan

Cylindrical lithium battery manufacturing in South Sudan

-

Cylindrical lithium battery expansion

Cylindrical lithium battery expansion

-

Bhutan custom made cylindrical lithium battery

Bhutan custom made cylindrical lithium battery

-

Large cylindrical 10ah lithium battery

Large cylindrical 10ah lithium battery

-

Cylindrical lithium battery into the box

Cylindrical lithium battery into the box

-

Lithium battery wholesale cylindrical

Lithium battery wholesale cylindrical

-

Croatia cylindrical lithium battery customization

Croatia cylindrical lithium battery customization

-

Lithium Cylindrical Battery

Lithium Cylindrical Battery

-

26500 cylindrical lithium battery

26500 cylindrical lithium battery

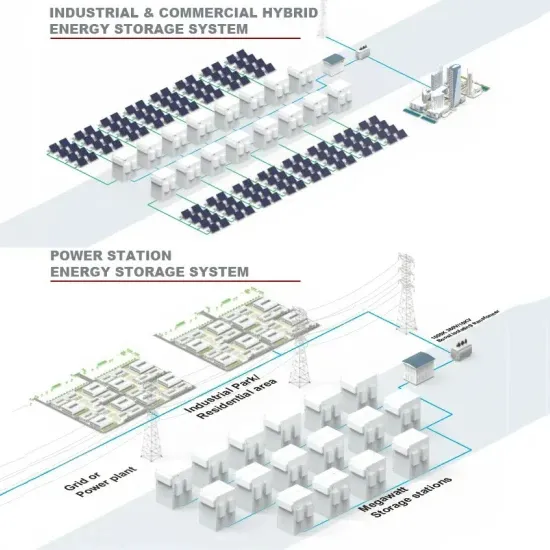

Commercial & Industrial Solar Storage Market Growth

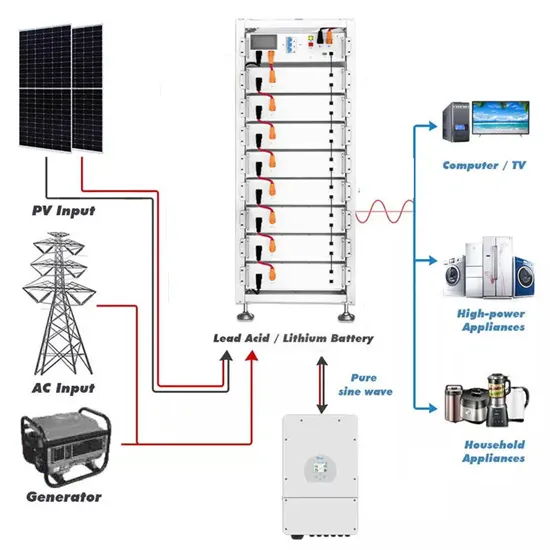

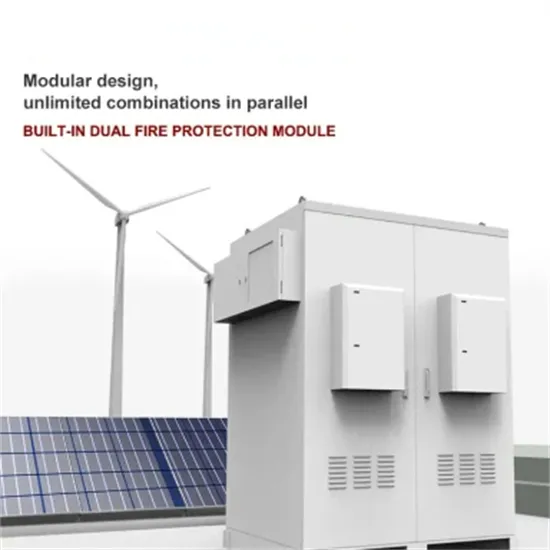

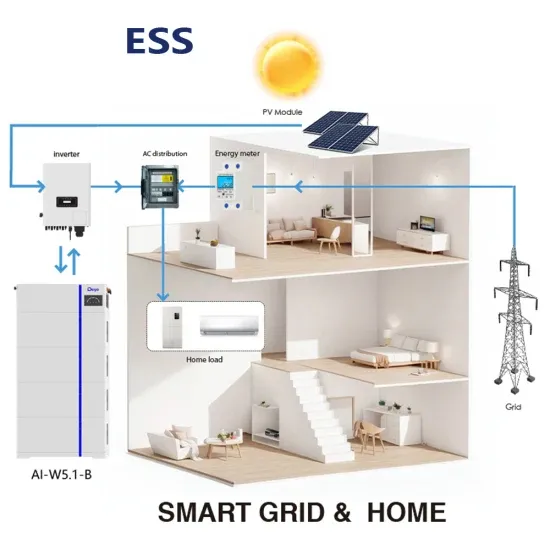

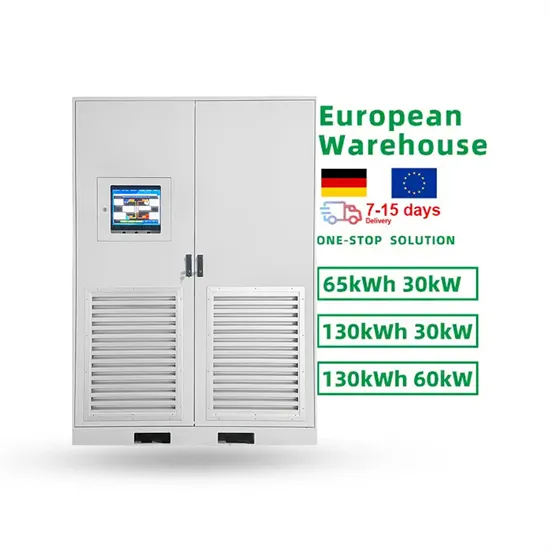

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

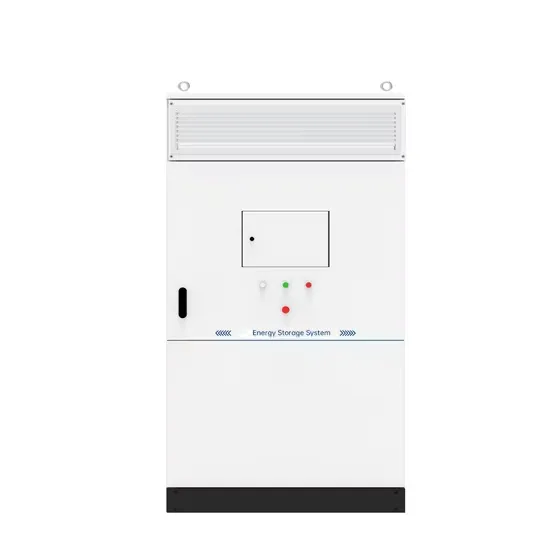

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.