Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · Cylindrical batteries have been explored as promising grid energy storage device, due to their high safety margin and low capital/maintenance costs. However, the practical

Get Started

Prismatic vs Cylindrical Batteries: Which Powers

Oct 15, 2024 · Dive into the battle of prismatic vs cylindrical batteries—size, energy, cost, and performance. Discover what''s powering the future of EVs

Get Started

Cylindrical Lithium Technologies

5 days ago · High Energy Formula contributes to Cylindrical Lithium''s long-lasting endurance in mid- and high-drain applications, such as cameras, where the

Get Started

Full Explanation of Lithium Battery Production

Aug 9, 2024 · What makes lithium-ion batteries so crucial in modern technology? The intricate production process involves more than 50 steps, from electrode

Get Started

The Three Major Li-ion Battery Form Factors:

Aug 16, 2023 · With lithium-ion batteries ever-rising in demand, it''s important to brush up on this battery''s three major form factors. Recently, we discussed the

Get Started

Thermal management characteristics of a novel cylindrical lithium

Oct 1, 2024 · Abstract To improve the thermal performance of large cylindrical lithium-ion batteries at high discharge rates while considering economy, a novel battery thermal management

Get Started

The Science of Cylindrical Cells: Understanding

Oct 11, 2024 · Cylindrical cells, also known as cylindrical lithium-ion batteries, are a type of rechargeable battery that are commonly used in various electronic

Get Started

Prismatic Cells vs. Cylindrical Cells: What is the

Apr 25, 2022 · There are three main types of lithium-ion batteries: cylindrical cells, prismatic cells, and pouch cells. In the EV industry, the most promising

Get Started

Prismatic vs Cylindrical vs Pouch Cells Comparison

Jan 4, 2024 · Diving into the dynamic world of battery technology, this article unravels the distinctive characteristics and applications of Cylindrical,

Get Started

Comparison on Thermal Runaway and Critical

Nov 15, 2024 · This review on the critical characteristics of cylindrical batteries under thermal failure and thermal abuse provides a reference for solving intrinsic safety issues for lithium-ion

Get Started

Cylindrical Cell manufacturing line

Apr 11, 2025 · What is a Cylindrical Cell Manufacturing Line? A Cylindrical Cell Manufacturing Line is an advanced industrial setup designed to mass-produce cylindrical lithium-ion batteries.

Get Started

Comparison of Different Packaging Methods for Lithium-ion Batteries

Digital products mainly use soft pack batteries, cylindrical batteries as cost-effective products to fill the market share. This article explains the lithium-ion battery packaging form, together with the

Get Started

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · The type of battery cell (pouch, prismatic, or cylindrical) is the foundation of your battery''s performance, reliability, and safety. Whether you''re powering an RV, marine vessel,

Get Started

Understanding Cylindrical Lithium-Ion Battery Sizes and

Feb 19, 2025 · Cylindrical lithium-ion batteries play a crucial role in the energy storage solutions of modern devices. From powering smartphones to electric vehicles, these batteries are

Get Started

Design, Properties, and Manufacturing of

Jun 3, 2023 · This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim

Get Started

Three Types of Lithium Battery Packaging and

As lithium batteries continue to dominate consumer electronics, electric vehicles (EVs), and energy storage systems, their packaging design plays a crucial

Get Started

Analysis of manufacturing processes of lithium batteries with

May 12, 2025 · Among the many characteristics of lithium batteries, the external form of packaging shape actually contains complex technical considerations and process logic. The

Get Started

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Get Started

Large and Small Cylindrical PACK Automated

Discover our automated assembly line tailored for 32135/40140 cylindrical lithium batteries, featuring high automation, precision, and compatibility. With key

Get Started

Understanding Cylindrical Lithium-Ion Battery

Feb 19, 2025 · In today''s technology-driven world, cylindrical lithium-ion batteries are more than just a power source—they are a fundamental component in

Get Started

BU-301a: Types of Battery Cells

Apr 24, 2019 · Some consumer Li-ion cells include the Charge Interrupt Device (CID) that physically and irreversibly disconnect the cell when activated to an

Get Started

How To Assembly Cylindrical Battery Pack?

1) Product Description Battery pack spot welder is used to weld nickel sheets with many lithium batteries into a group pack, which is suitable for battery pack

Get Started

EV Battery Cell Formats for Lithium Metal

Jan 16, 2024 · There are several ways to package EV battery cells – cylindrical, prismatic and pouch. Each offers unique tradeoffs, and there is currently no clear winner among the three

Get Started

Cylindrical Cell Battery Assembly Line

2 days ago · Mainly used for automatic bottom pad flushing, cell detection, battery core insertion into steel shell, automatic bottom welding, automatic top sheet

Get Started

Prismatic vs Cylindrical Battery Cells: What''s the

Explore the depths of prismatic and cylindrical battery cells. Dive into a comprehensive guide comparing cost, design, and application in modern tech.

Get Started

Liquid-immersed thermal management to cylindrical lithium-ion batteries

Apr 30, 2024 · Immersed thermal management shows distinct advantages while cooling the lithium-ion battery modules. This work conducts numerical-experimental studies to analyze the

Get Started

Cylinder Cell Automatic Assembly Line Equipment for Lithium Ion Battery

Jul 29, 2025 · CYLINDER CELL AUTOMATIC ASSEMBLY LINE It is mainly used for cylindrical lithium battery automatic putting of the bottom insulator, battery core detection, putting battery

Get Started

Core collapse in cylindrical Li-ion batteries

Dec 15, 2024 · The phenomena of core collapse observed in cylindrical lithium-ion batteries offer valuable insights that apply to other battery formats by revealing fundamental principles of

Get Started

EV Battery Cell Formats for Lithium Metal

Jan 16, 2024 · Despite these drawbacks, the cylindrical cell is still prevalent due to some of its unique advantages. For example, as lithium-ion batteries age,

Get Started

CYLINDRICAL

Jul 1, 2024 · Abstract—The advancement of new energy vehicles has led to more demanding standards for detecting defects in cylindrical coated lithium batteries. The current research

Get Started

Prismatic Cells and Cylindrical Cells Compared

Feb 24, 2025 · There are three main varieties of lithium-ion batteries, namely prismatic, cylindrical, and pouch types. The first two battery types seem to be forging ahead of pouch

Get Started

Easy lithium box technology, a new way of building cylindrical

Mar 7, 2022 · Hi, I''ve been studying lithium tech since 2005 and I want to materialize an easy box technology for LiFePO4 and eventually Li-ion cells, to build for small vehicles. It''s also a tool to

Get Started

6 FAQs about [Cylindrical lithium battery into the box]

Are cylindrical batteries suitable for lithium-metal batteries?

Ultimately, we don’t believe cylindrical formats are suitable for lithium-metal battery cells. Despite what the name might suggest, the prismatic battery cell is essentially a rectangular metal box. The individual layers of the battery are either stacked like a deck of cards or wound up and then pressed flat to fit into the cell casing.

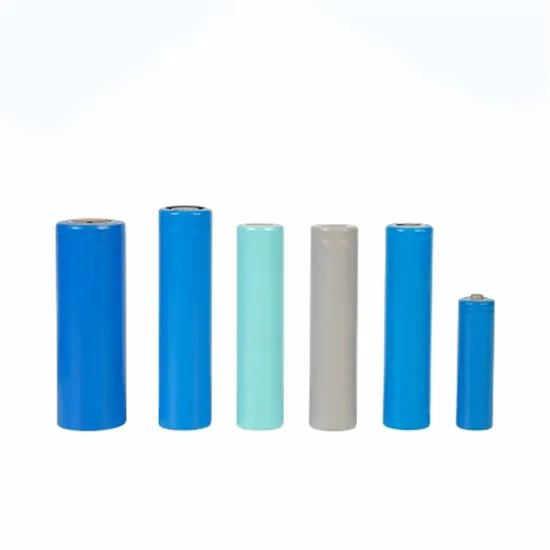

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

What is a cylindrical battery?

This durability is why many industries use cylindrical cells in power tools, electric vehicles, and battery banks that experience rough handling or frequent travel. Prismatic cells (rectangular lithium batteries) are encased in a rigid aluminum or steel shell. The shell provides solid protection for stationary or gently handled applications.

What are the naming rules for lithium ion batteries?

The naming rules for cylindrical lithium-ion battery cells follows a standardized format based on the cell’s dimensions, and usually represented by a five-digit code, where each digit provides specific information about the cell’s dimensions. Here’s a breakdown of the representation: What does 18650 means?

What is the difference between a lithium-metal and a conventional lithium-ion battery?

The most crucial difference between a lithium-metal cell and a conventional lithium-ion battery is that the cell expands as lithium plates directly on the separator of a lithium-metal cell. As such, the overall cell is thicker when fully charged.

Related Articles

-

Cylindrical lithium battery into the box

Cylindrical lithium battery into the box

-

Cost structure of cylindrical lithium iron phosphate battery

Cost structure of cylindrical lithium iron phosphate battery

-

Cylindrical lithium battery automatic charging equipment

Cylindrical lithium battery automatic charging equipment

-

Italian Milan cylindrical lithium battery millivolt

Italian Milan cylindrical lithium battery millivolt

-

Bhutan custom made cylindrical lithium battery

Bhutan custom made cylindrical lithium battery

-

26500 cylindrical lithium battery

26500 cylindrical lithium battery

-

Huawei cylindrical lithium battery procurement channels

Huawei cylindrical lithium battery procurement channels

-

Cambodia small cylindrical lithium iron phosphate battery

Cambodia small cylindrical lithium iron phosphate battery

-

4V 2600mh cylindrical lithium battery price

4V 2600mh cylindrical lithium battery price

-

Roman cylindrical lithium battery price

Roman cylindrical lithium battery price

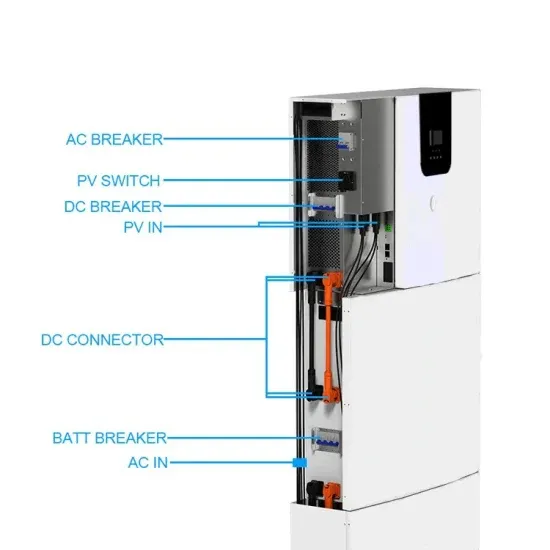

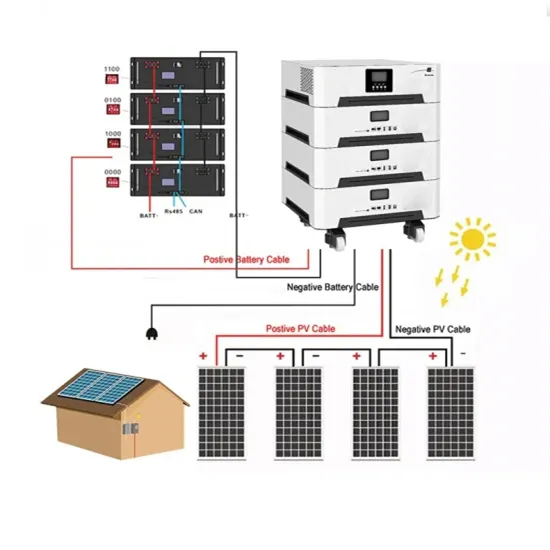

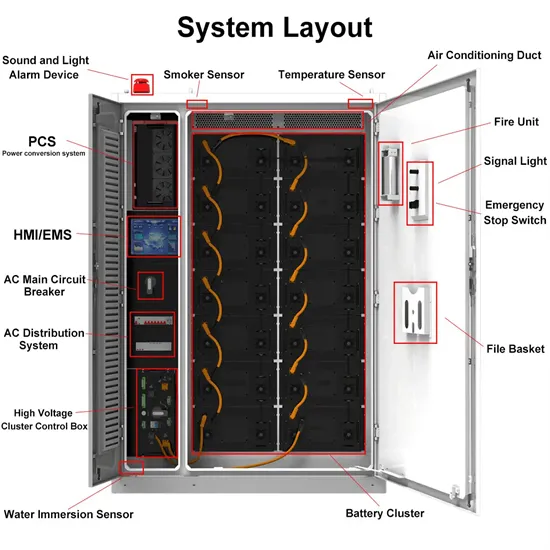

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.